Assembly and method for acoustically influencing toothed wheels

A technology of gears and components, applied to components with teeth, belts/chains/gears, gear teeth, etc., can solve problems such as increased noise and achieve the effect of reducing noise levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

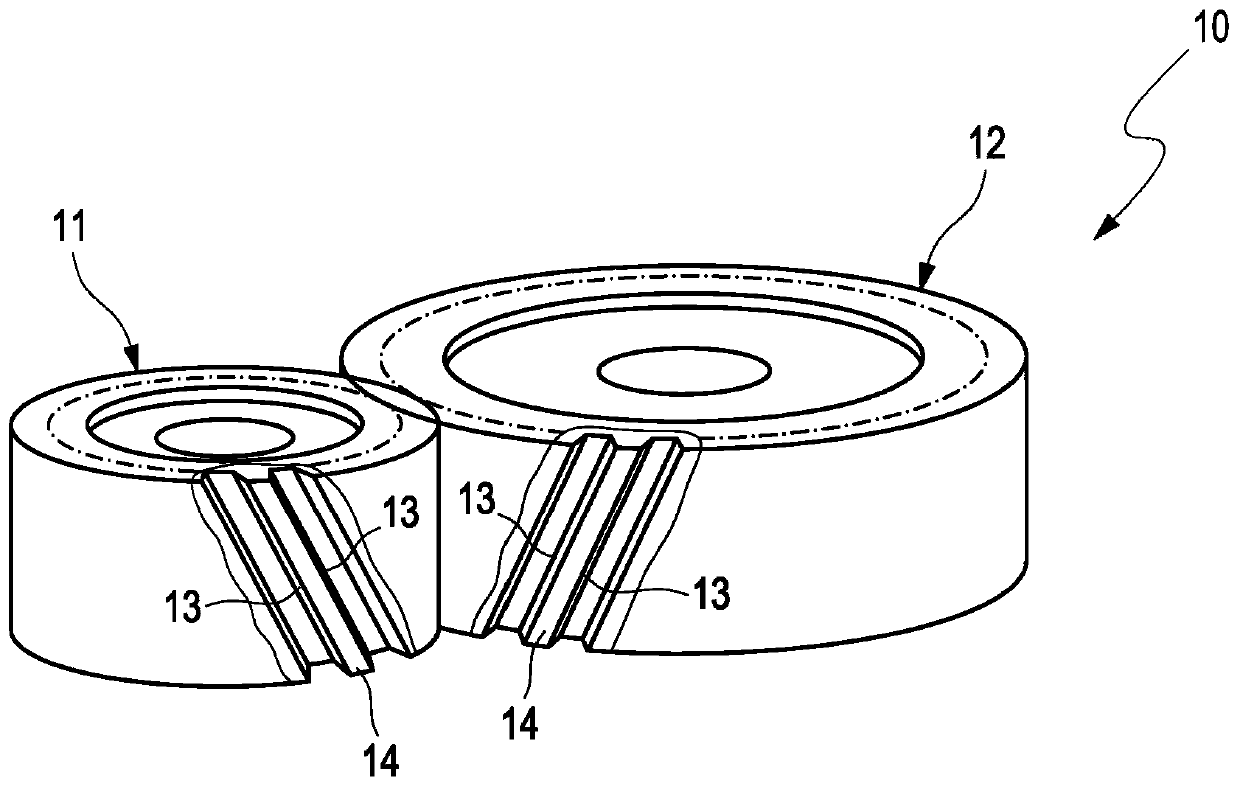

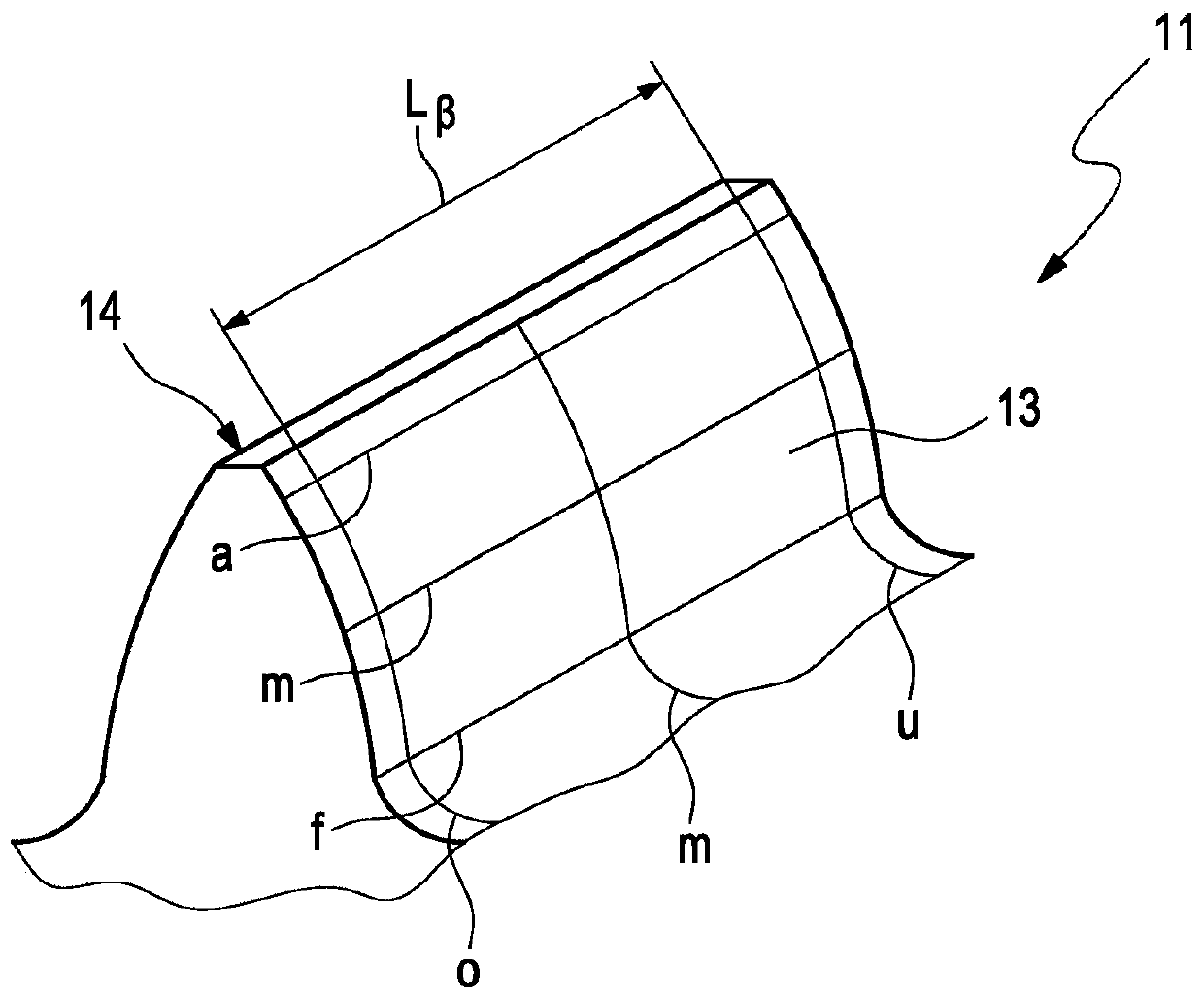

[0034] exist figure 1 A schematic diagram of the arrangement of an embodiment of an assembly 10 according to the present invention is shown in FIG. 1 , which includes a first gear 11 and a second gear 12 , as an example of a helical gear. Here, both the first gear wheel 11 and the second gear wheel 12 have teeth 14 . The teeth 14 each have a tooth flank 13 here. At least one tooth flank 13 of a tooth 14 of the first gearwheel 11 can mesh with a tooth flank 13 of a tooth 14 of the second gearwheel 12 . According to the invention, when the tooth flanks 13 of the teeth 14 of the first gearwheel 11 mesh into the tooth flanks 13 of the teeth 14 of the second gearwheel 12, there is formed—not at figure 1 Shown in - a contact line or a contact area forming an acute or obtuse angle with the corrugation axis of the tooth flank 13 of the tooth 14 of the first gear 11 and / or the second gear 12 . In this case, the contact line or the contact zone is formed based on the configuration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com