Bombyx mori artificial feed feeding device

A technology of artificial feed and cutting device, which is applied in animal husbandry and other directions, can solve the problems of uneven growth and development of silkworms, low slicing efficiency, uneven slicing, etc., and achieves controllable slice thickness, high cutting efficiency, and improved income. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

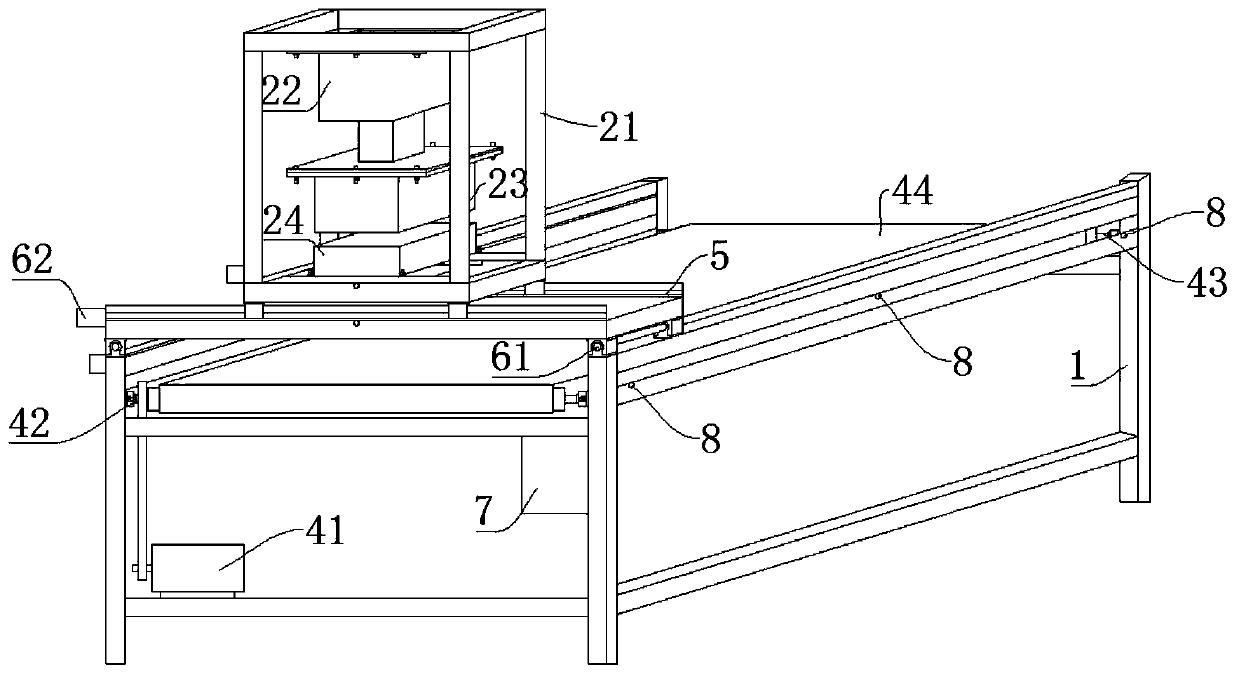

[0021] Such as Figure 1~2 As shown, a silkworm artificial feed feeding device includes a frame 1, a transmission device and a slicing device, the transmission device is installed on the frame 1, and the transmission device includes a transmission motor 41, a front roller 42, a rear roller 43 and a conveyor belt 44 , the front roller 42 and the rear roller 43 are arranged side by side and rotated respectively on the frame 1, the transmission motor 41 is connected to the front roller 42, and the conveyor belt 44 is arranged between the front roller 42 and the rear roller 43, The conveying device moves the feed receiving plane horizontally to increase the feed receiving surface and reduce the feed sticking caused by the extrusion of the feed strength.

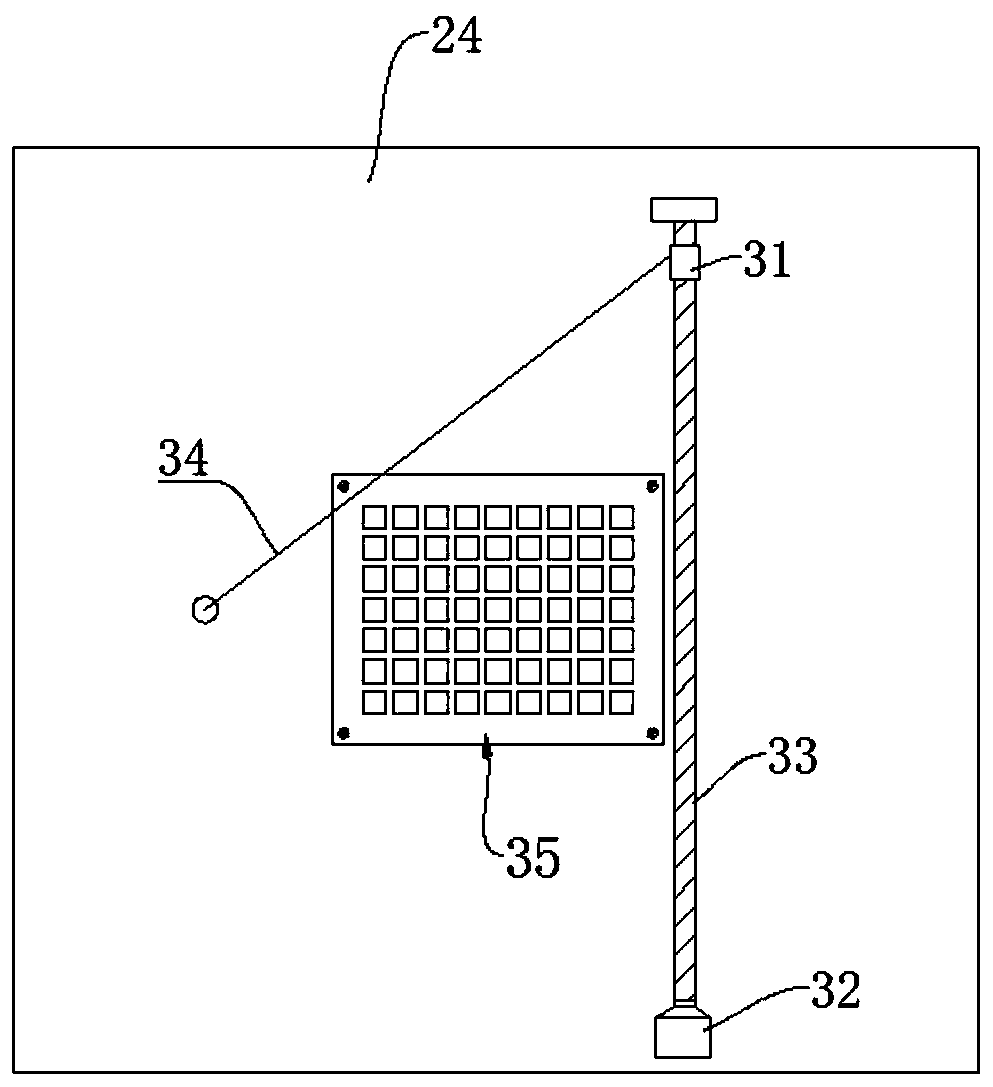

[0022] The slicing device is installed above the conveying device. The slicing device includes a support 21, a feeding device and a material cutting device. A feeding device is installed above the support 21. The feeding device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com