A biological trickling filter tower for organic waste gas treatment and its use method

A technology of biological trickling filter tower and organic waste gas, which is applied in separation methods, chemical instruments and methods, air quality improvement, etc., and can solve problems such as plugging packing and affecting purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

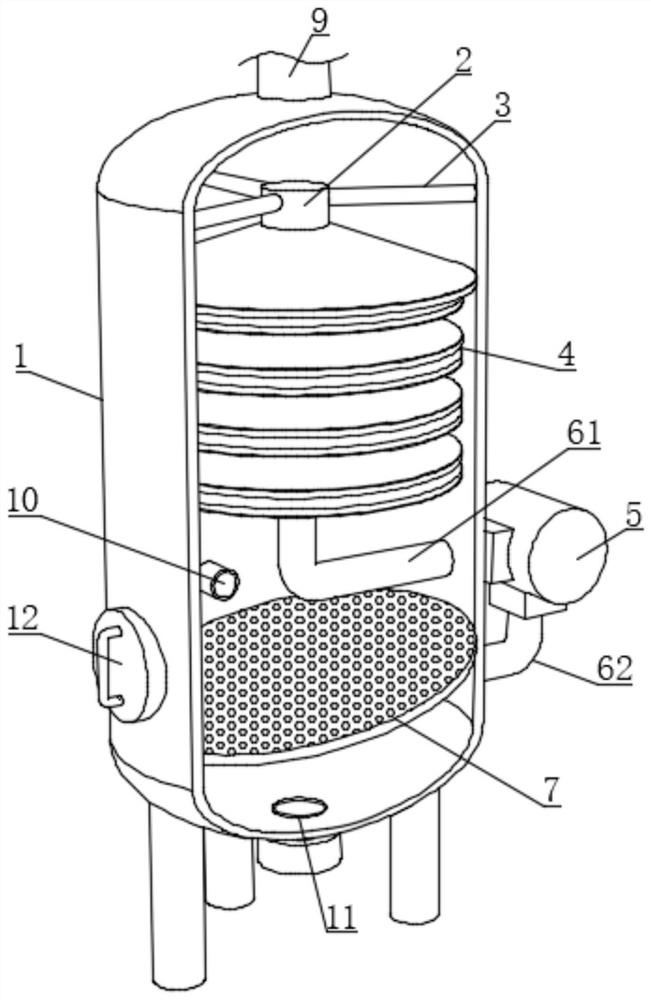

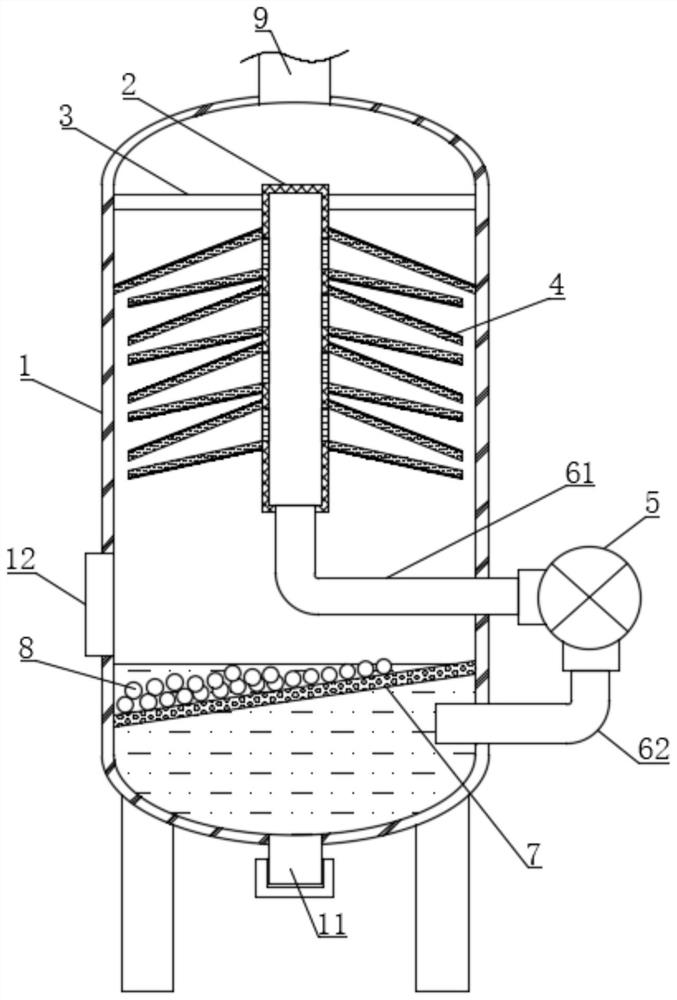

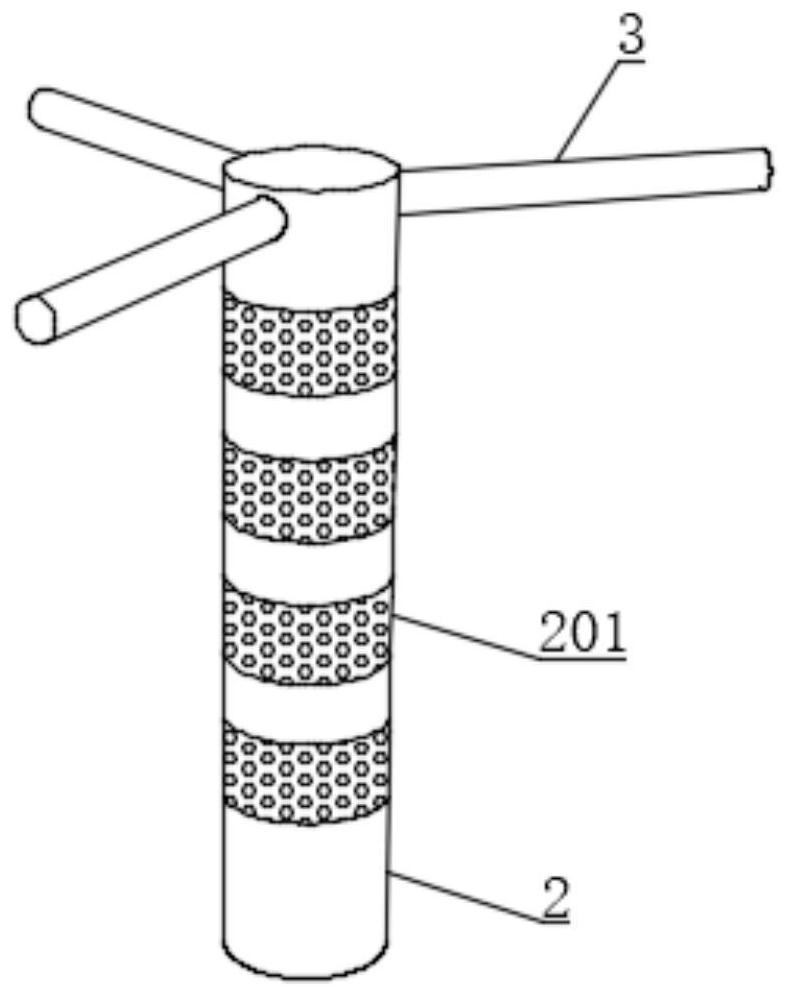

[0043] see figure 1 and figure 2 , a biological trickling filter tower for organic waste gas treatment, comprising a tower body shell 1 and a circulation pump 5, the upper end of the tower body shell 1 is fixedly connected with an outlet pipe 9, and the outer end of the tower body shell 1 is fixedly connected with an air inlet pipe 10 The lower end of the tower body shell 1 is fixedly connected with a drain pipe 11, and the outer end of the drain pipe 11 is threadedly connected with a pipe cover, and the inside of the tower body shell 1 is filled with a nutrient solution, which is the nutrient solution required for microbial growth and The mixed solution of clear water, the inside of the tower shell 1 is provided with a guide tube 2, and a plurality of evenly distributed fixed rods 3 are fixedly connected between the outer end of the guide tube 2 and the inner wall of the tower shell 1, and the fixed rods 3 To fix the role of the guide tube 2, the outer end of the guide tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com