Worm-type graphite-filled structure wear-resistant plate and preparation method thereof

A wear-resistant plate and graphite technology, which is applied in the field of wear-resistant plate manufacturing, can solve the problems of low oil content, reduced mechanical strength of wear-resistant materials, and high friction coefficient, and achieves the effect of high oil content and good self-lubricating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

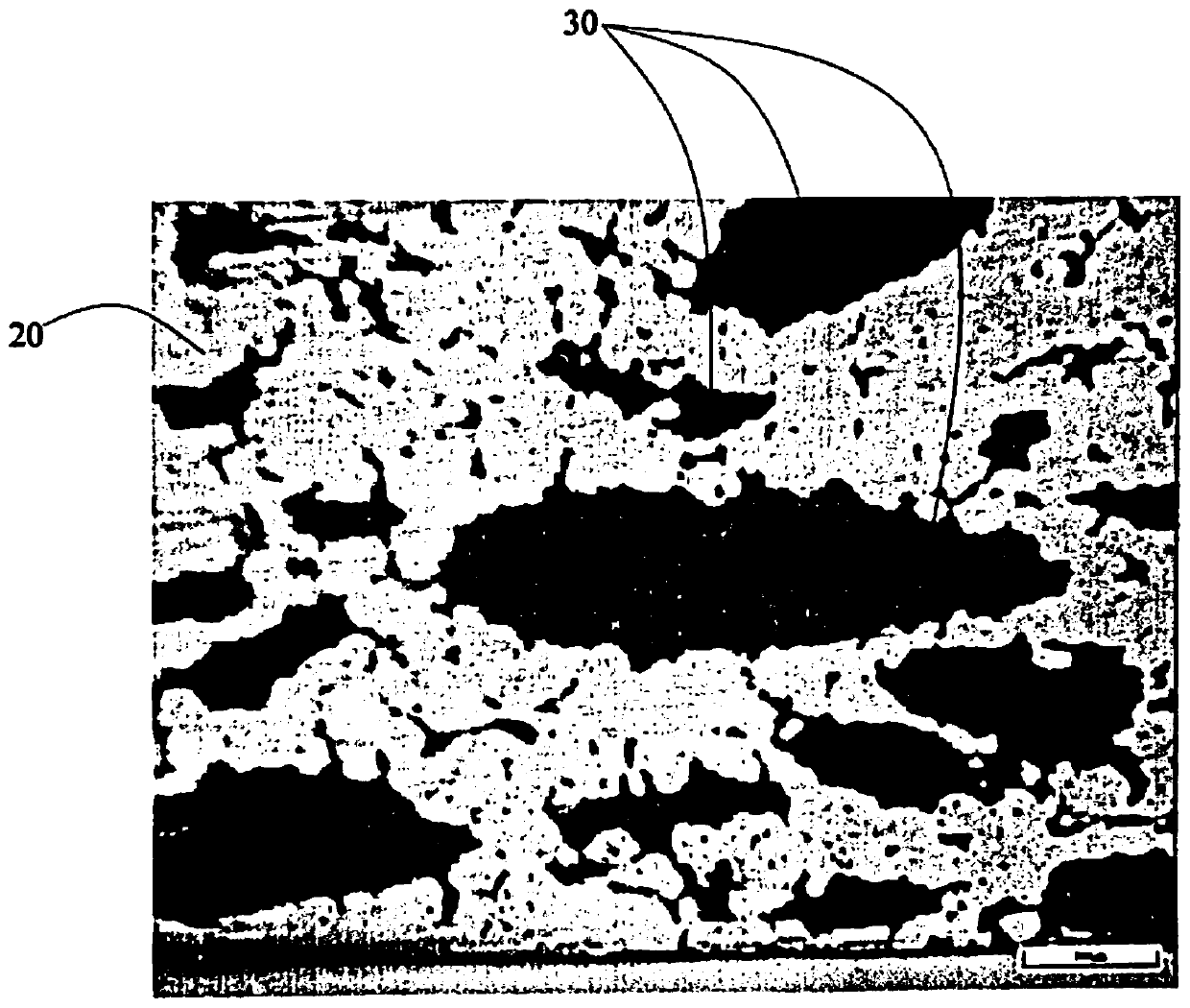

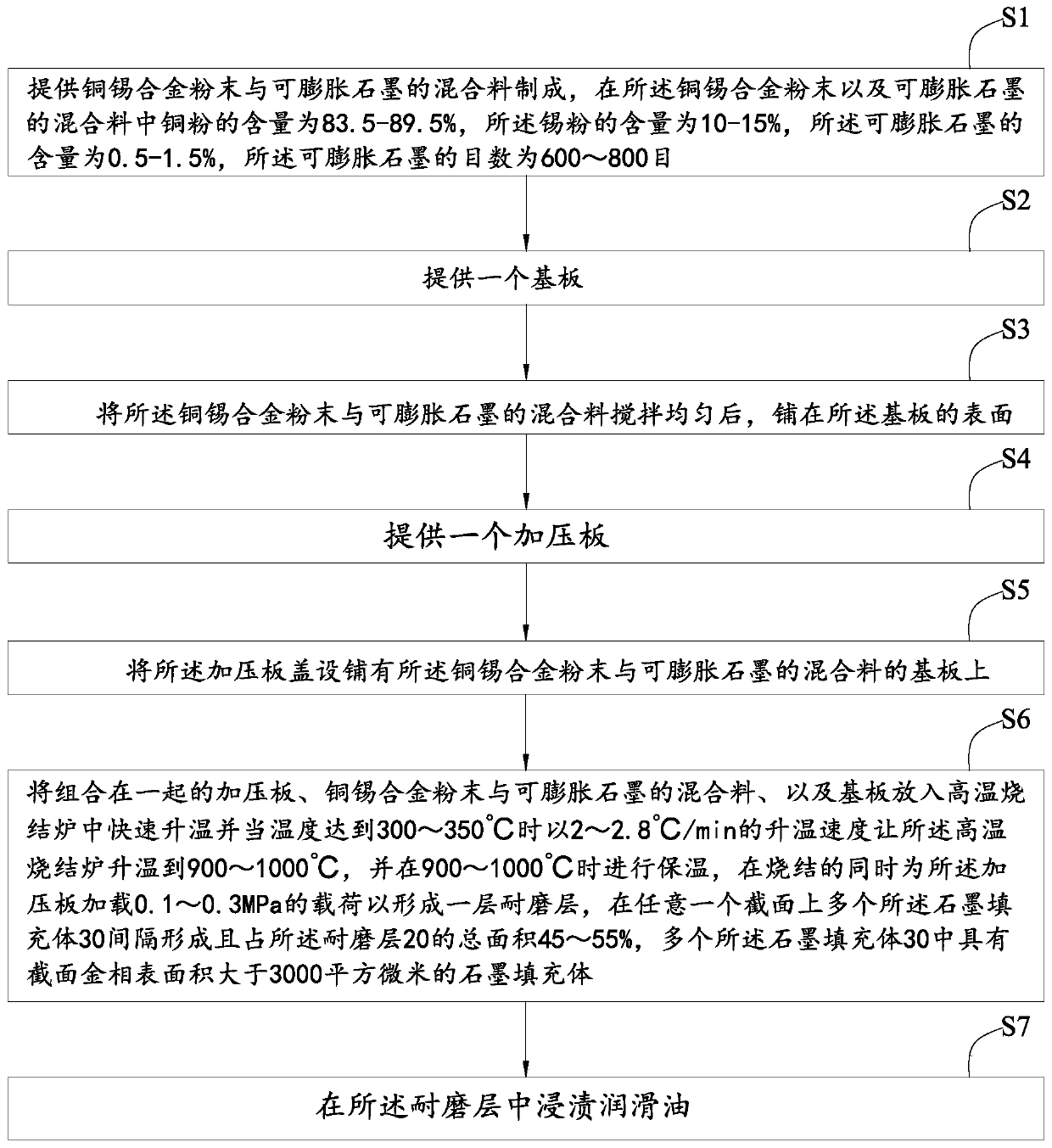

[0033] Such as image 3 As shown, the present invention also provides a method for preparing the worm-type graphite-filled structure wear-resistant plate, which includes the following steps:

[0034] S1: It is made by providing a mixture of copper-tin alloy powder and expandable graphite. The content of copper powder in the mixture of copper-tin alloy powder and expandable graphite is 83.5-89.5%, and the content of tin powder is 10% ~15%, the content of the expandable graphite is 0.5-1.5%, and the mesh number of the expandable graphite is 600-800 mesh;

[0035] S2: provide a substrate 10;

[0036] S3: spread the mixture of the copper-tin alloy powder and the expandable graphite evenly on the surface of the substrate 10;

[0037] S4: a pressure plate is provided; the pressure plate can be made of metal material;

[0038] S5: Covering the pressure plate on the substrate 10 covered with the mixture of the copper-tin alloy powder and expandable graphite;

[0039] S6: Put the c...

Embodiment

[0042] Provide the mixture of copper-tin alloy powder and expandable graphite, the content of copper powder in the mixture of copper-tin alloy powder and expandable graphite is 87%, the content of tin powder is 12%, the The content of expandable graphite is 1.0%, and the mesh number of the expandable graphite is 600-800 mesh; strictly follow the heating curve to raise the temperature of the high-temperature sintering furnace to 930 at a rate of 2.5°C / min after reaching 350°C ℃, and a load of 0.25 MPa is applied to the pressurized plate while sintering to obtain the worm-type graphite-filled structure wear-resistant plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com