Pogo pin probe slotting necking machine and working method thereof

A technology of closing machine and probe, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve problems such as low efficiency, increased burden, waste of labor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

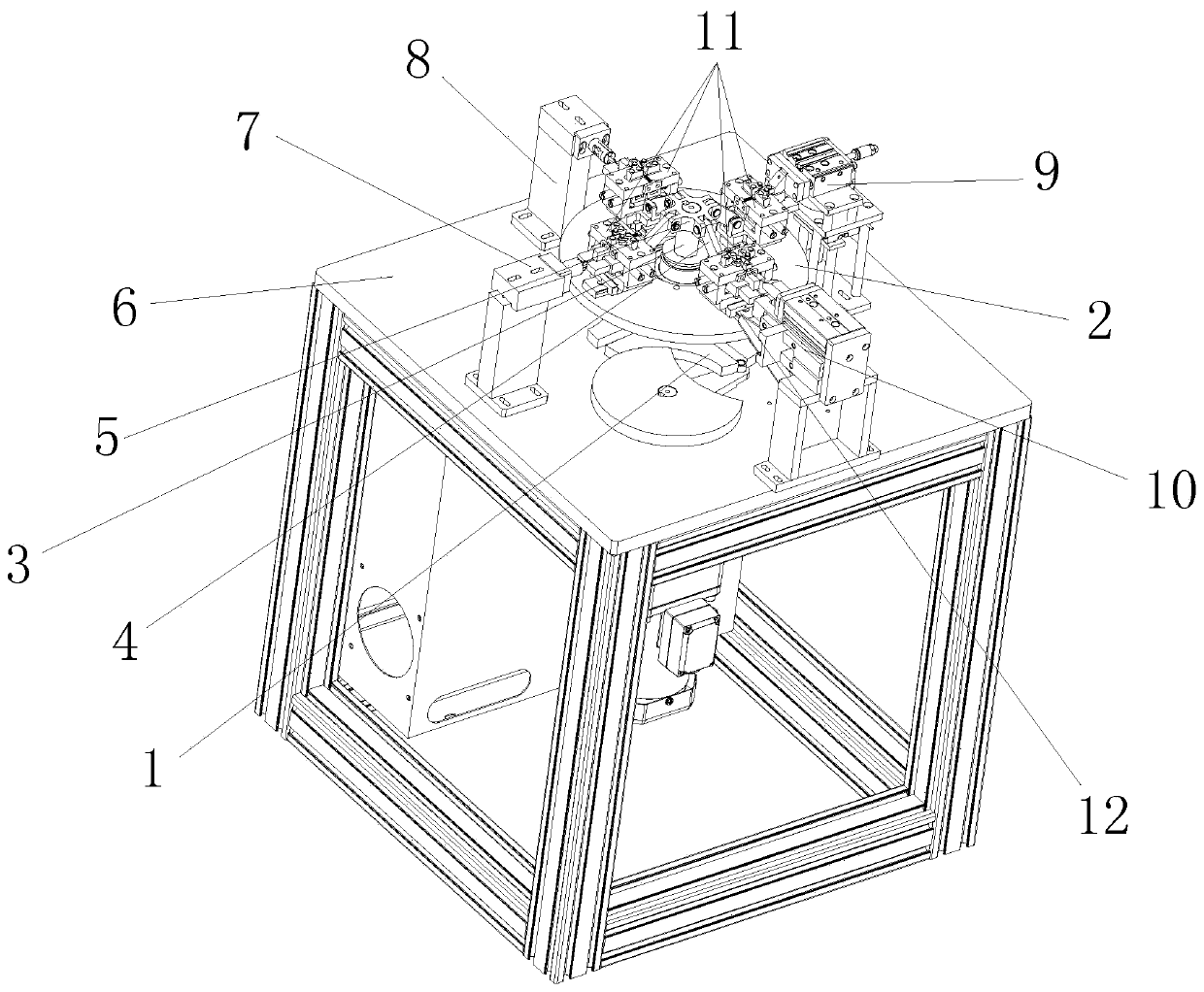

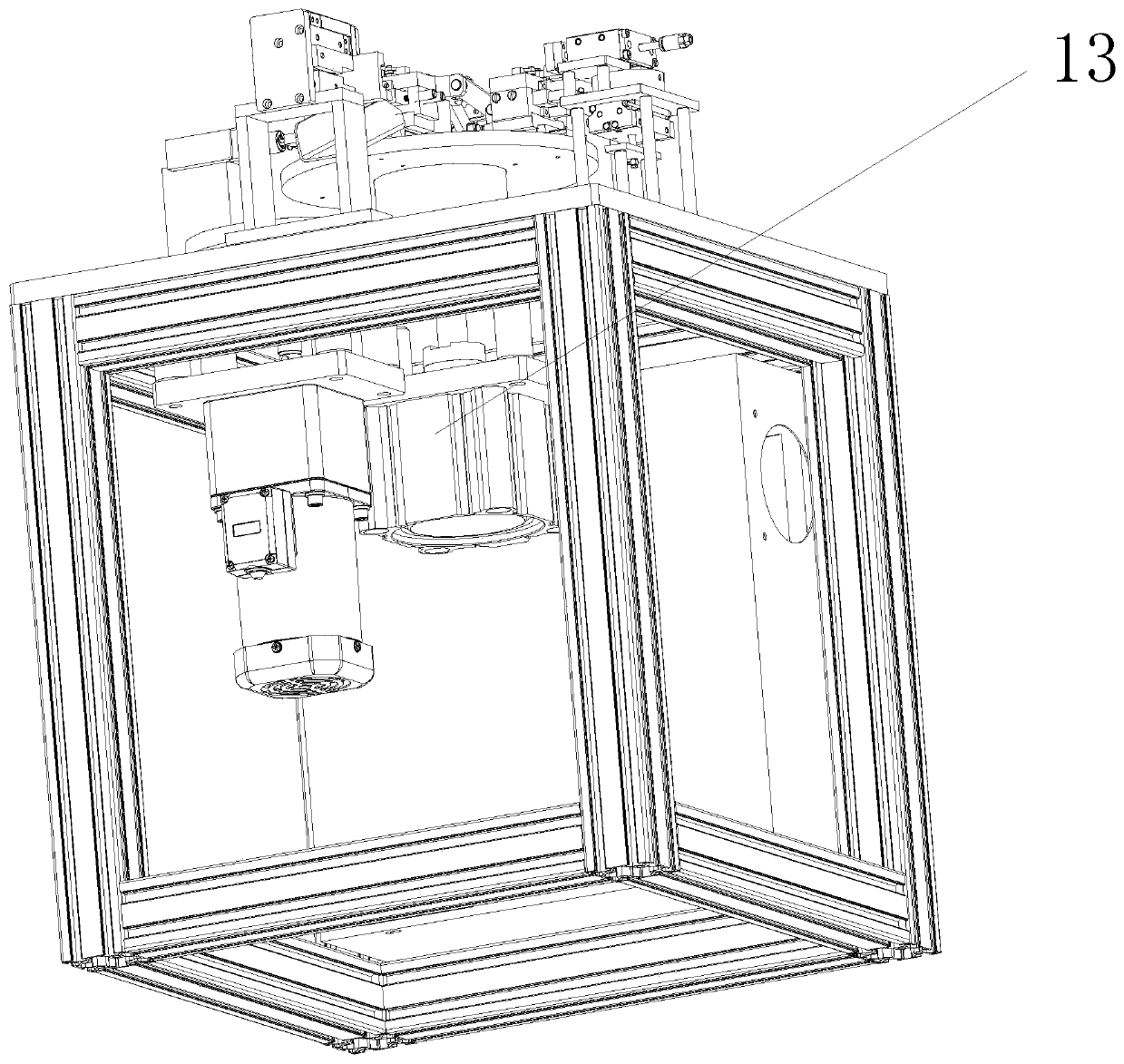

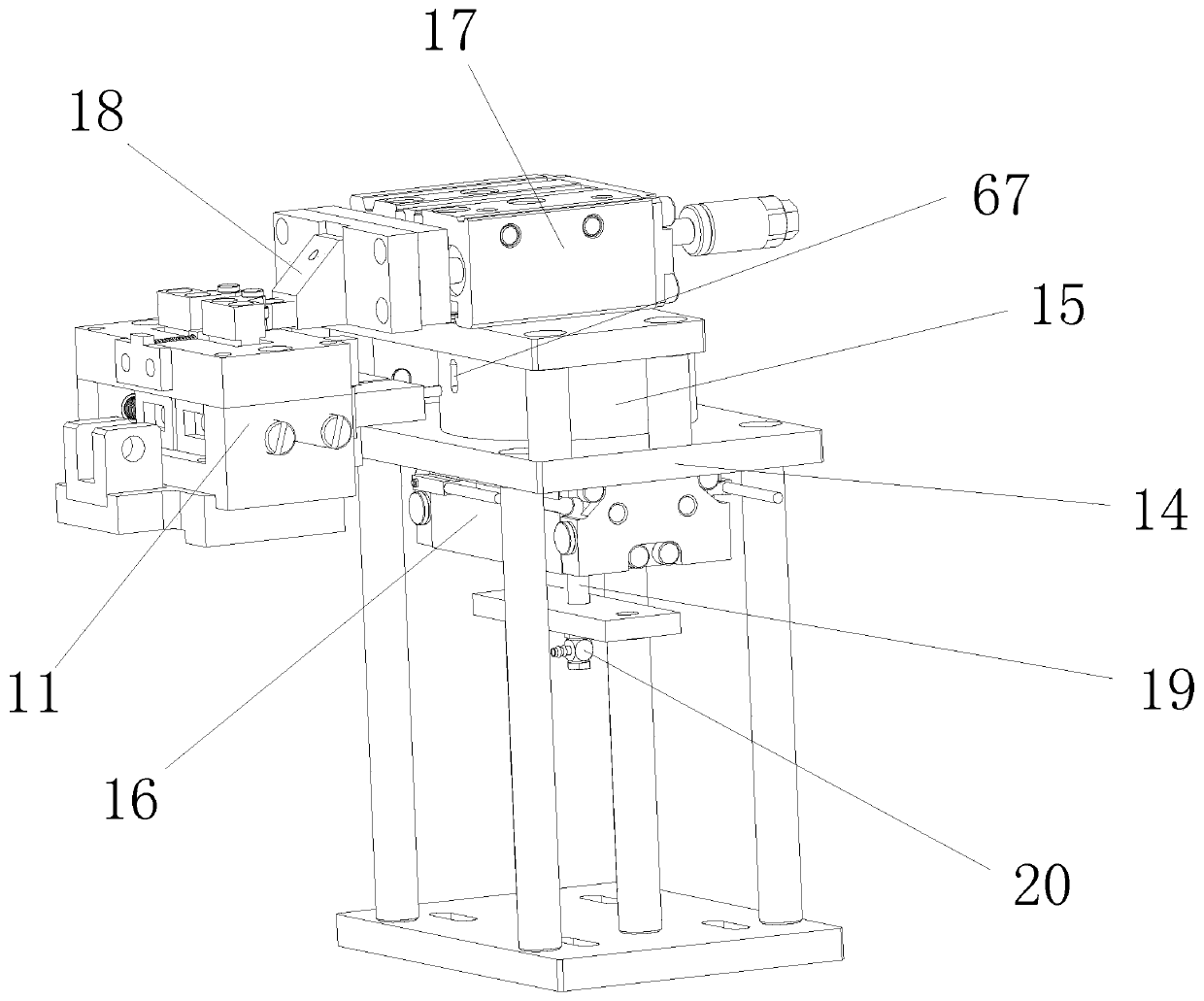

[0047] Such as figure 1 , 2, 8 and 9, a pogo pin probe slotting and closing machine includes a frame 6, a turntable 2 arranged on the frame 6, a lifting cylinder 13 and an intermittent rotation mechanism 1 for driving the turntable 2 to rotate intermittently, The intermittent rotating mechanism 1 is an existing sheave intermittent mechanism. When the intermittent rotating mechanism 1 starts, it can drive the turntable 2 to rotate intermittently on the frame 6. The intermittent rotating mechanism 1 can drive the turntable 2 to rotate 90 degrees every time it is started. Four clamping mechanisms 11 for clamping the workpiece 26 are arranged at intervals on the top. The lifting rod 3 is connected to the piston rod of the lifting cylinder 13, and the end of the lifting rod 3 away from the lifting cylinder 13 is provided with a clamping mechanism 11 to cooperate with the clamping mechanism 11. The rotary frame 5, the clamping mechanism 11 includes a clamping seat 28 slidably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com