Assembly line of packing box

An assembly line and packaging box technology, applied in the field of packaging, can solve problems such as affecting assembly quality, paper being susceptible to moisture and deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

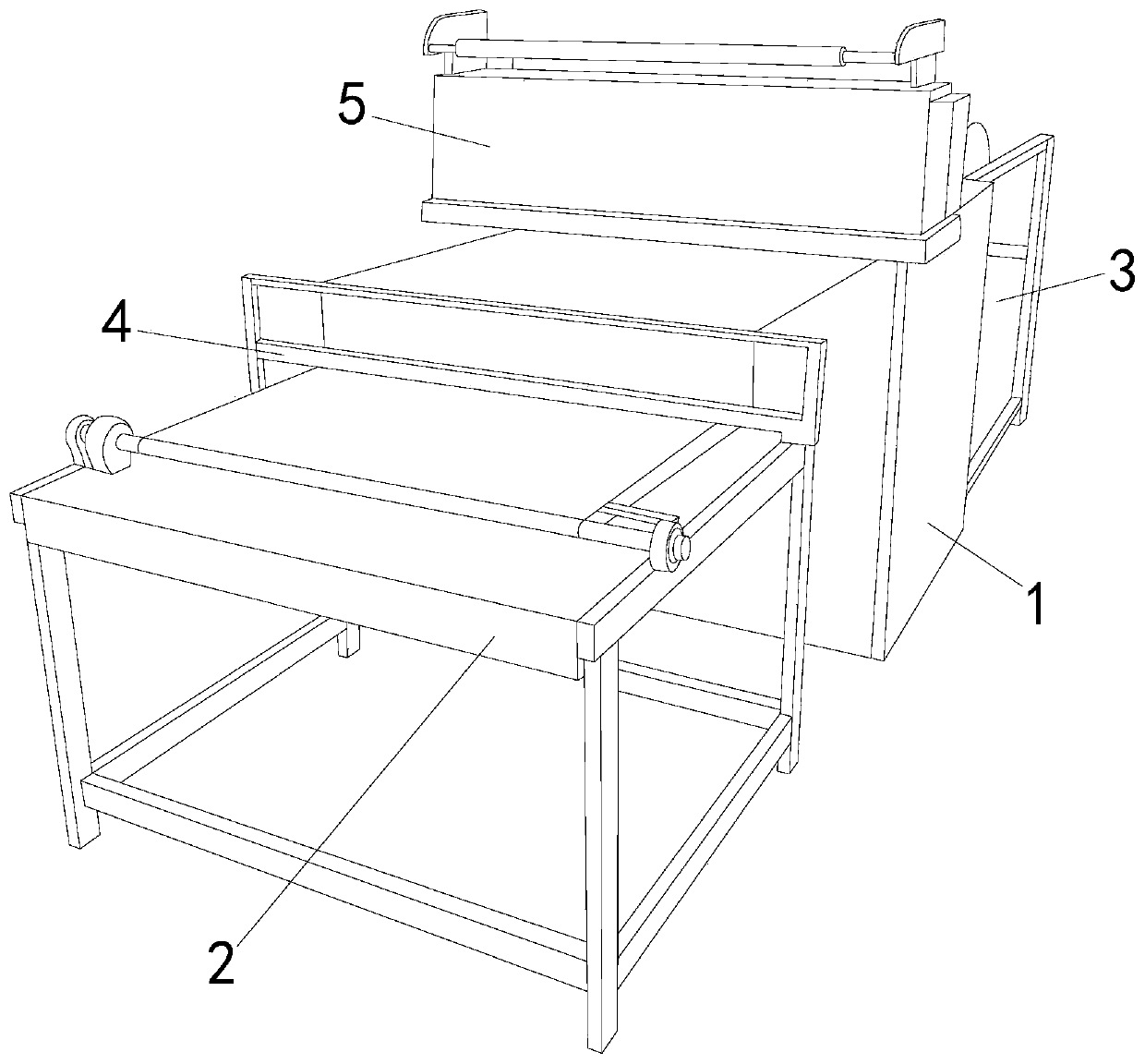

[0023] see figure 1 , the present invention provides an assembly line for packaging boxes, the structure of which includes: a body 1, an output platform 2, an input platform 3, an elevated shelf 4, and a welt moisture-proof mechanism 5, and the two ends of the body 1 are respectively provided with an output platform 2 and the input table 3, the top surface of the output table 2 is provided with a whole elevated frame 4 and it is located on the side of the welt moisture-proof mechanism 5, the bottom of the welt moisture-proof mechanism 5 is attached to the fuselage 1, and the fuselage 1 is the main structure of the assembly line equipment , which is a rectangular box structure as a whole, which is used to carry the mechanical components and electronic circuits required for the operation of the equipment. It can also be used to carry the weight of the welt moisture-proof mechanism 5 to maintain its structural stability. Its height is flush with the input platform 3 but higher t...

Embodiment 2

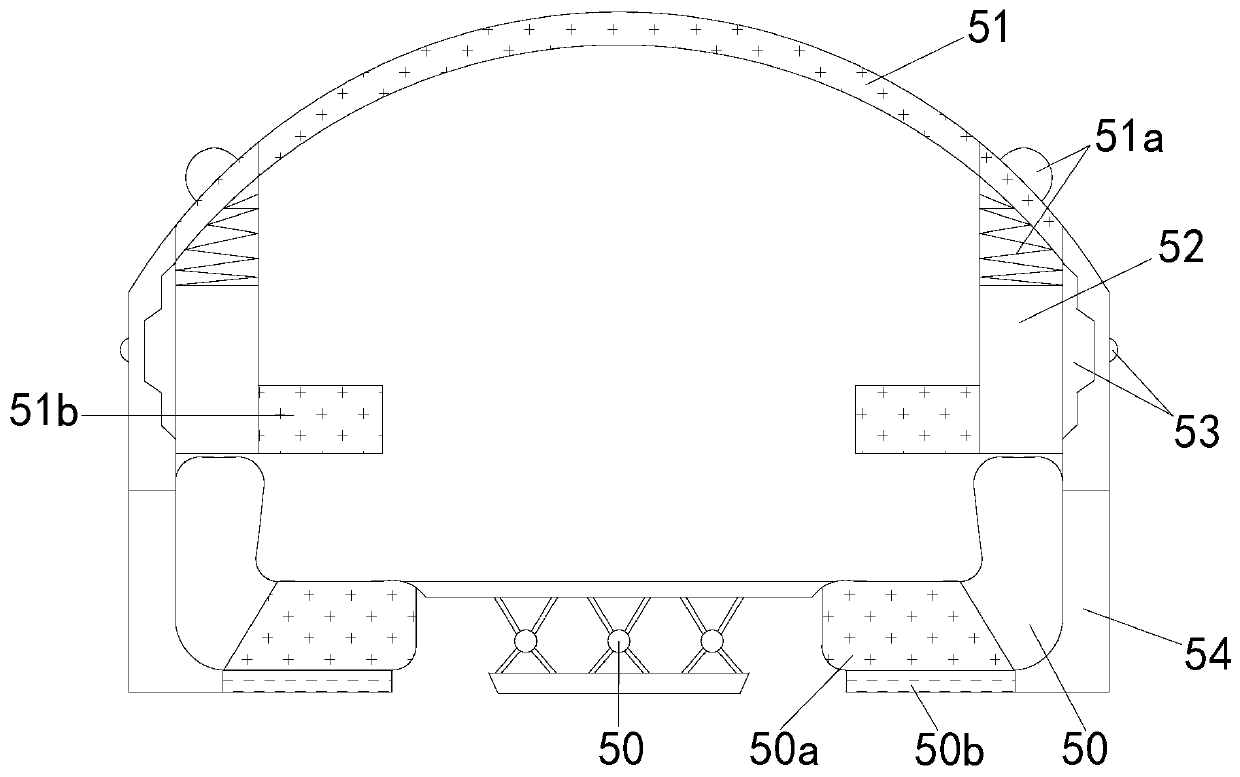

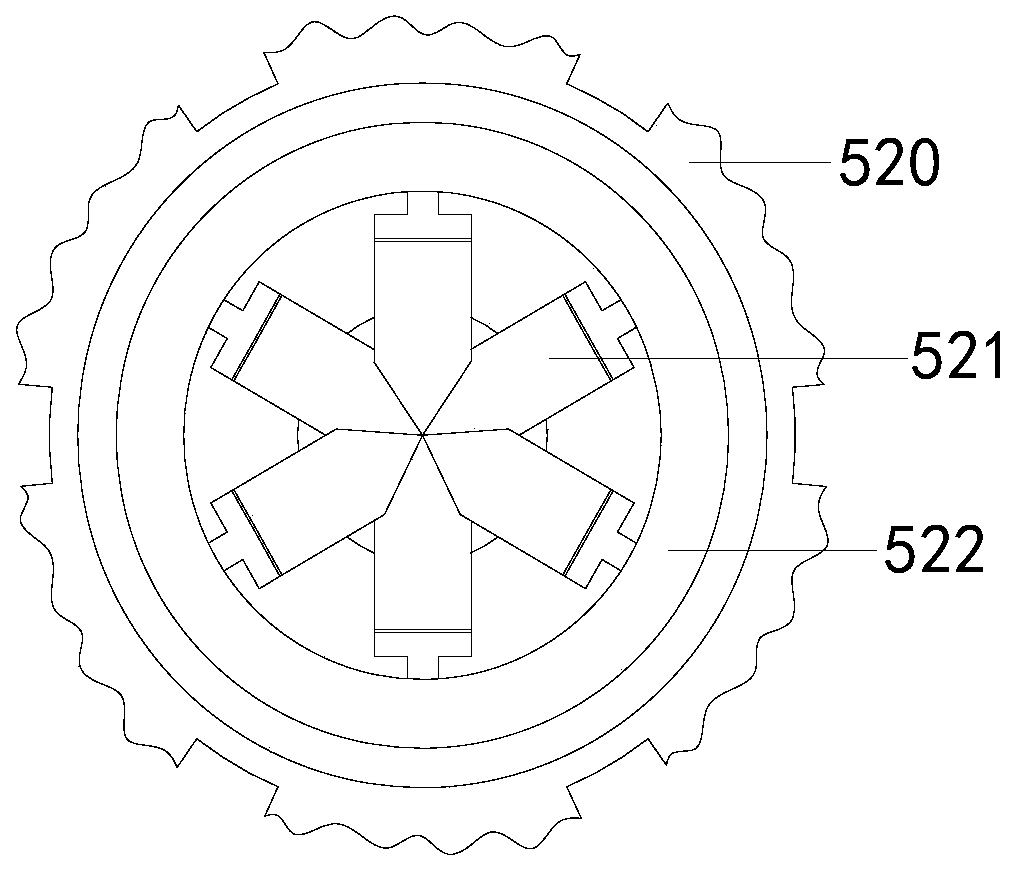

[0029] The description of the second embodiment drawn in conjunction with the first embodiment, combined with figure 2 and Figure 5 , the position above the cross truss 50 is provided with an arched magnetic top 51, the bottom ends of both sides of the arched magnetic top 51 are connected to the adjustment tooth plate 53 through the counterweight ring 52, the adjustment tooth plate 53 is located at the top of the paper drying rack 54 and the two are connected to each other. One side of the support 540 is provided with a hot air chamber 541 and the two are connected to each other. The side of the hot air chamber 541 is connected to the winding column 542. The magnetic repulsion force generated by the N-pole magnetic plate 51b and its reaction will form a downward pressure on the paper surface, and at the same time, the bottom and edge of the paper are close to the paper drying rack 54, and the electric heating tube 540b heats and conducts heat to the hot air chamber 541, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com