Environment-friendly multifunctional garbage recycling machine

A multi-functional, recycling machine technology, applied in garbage collection, trash cans, household appliances, etc., can solve problems such as carbonated beverage splashing, electrode surface wall thickness thinning, oxygen absorption corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

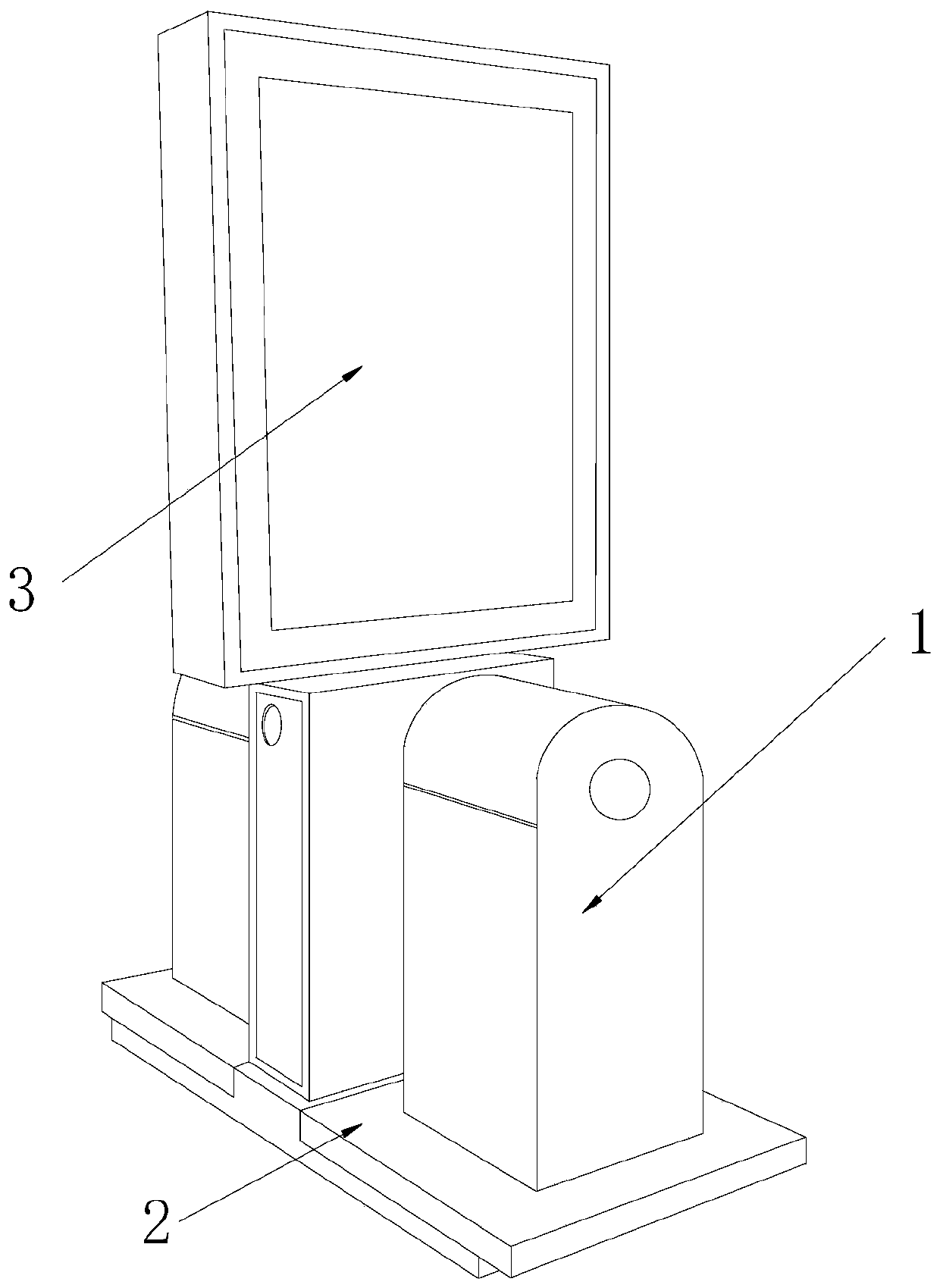

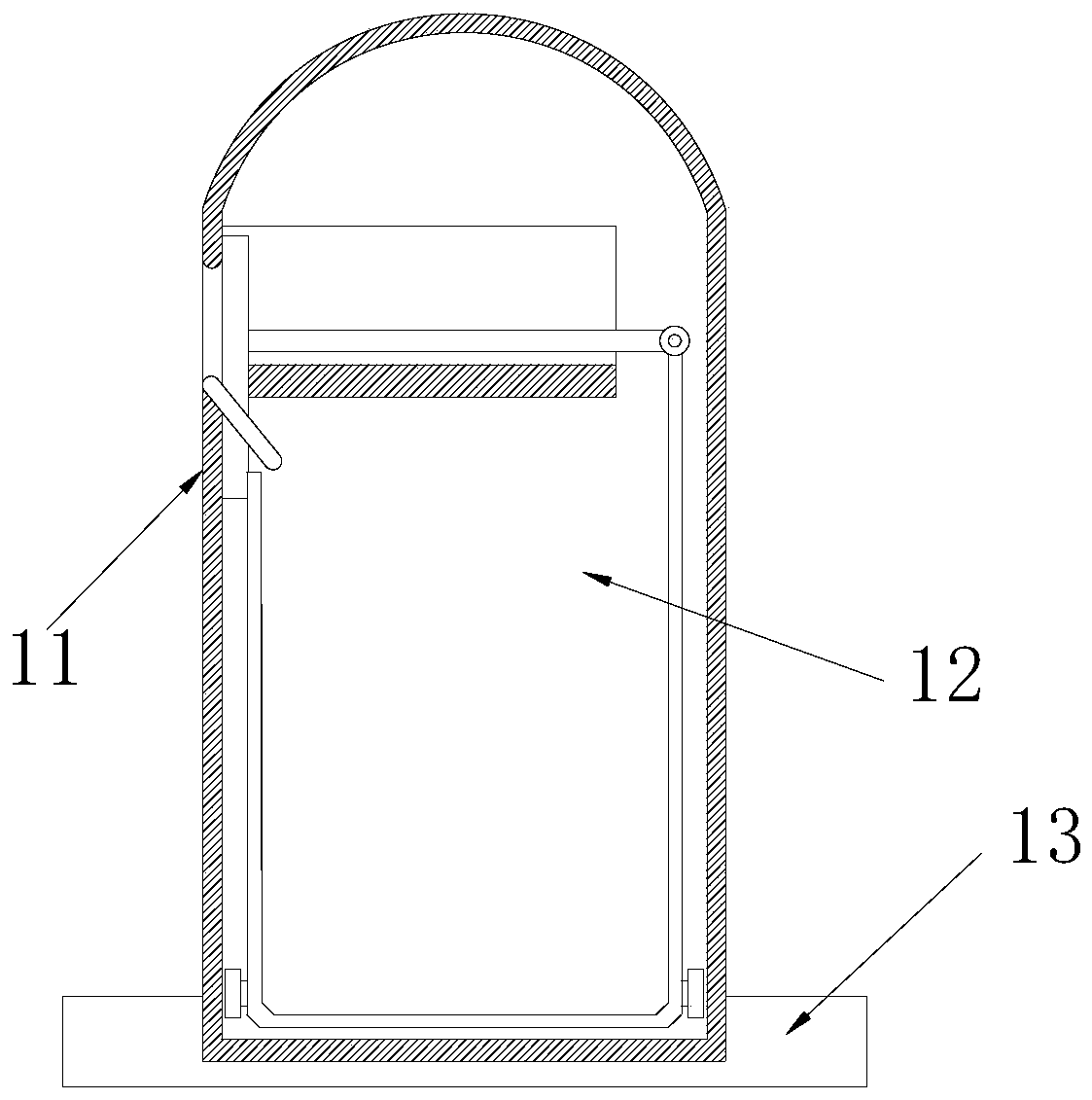

[0027] as attached figure 1 to attach Figure 5 Shown:

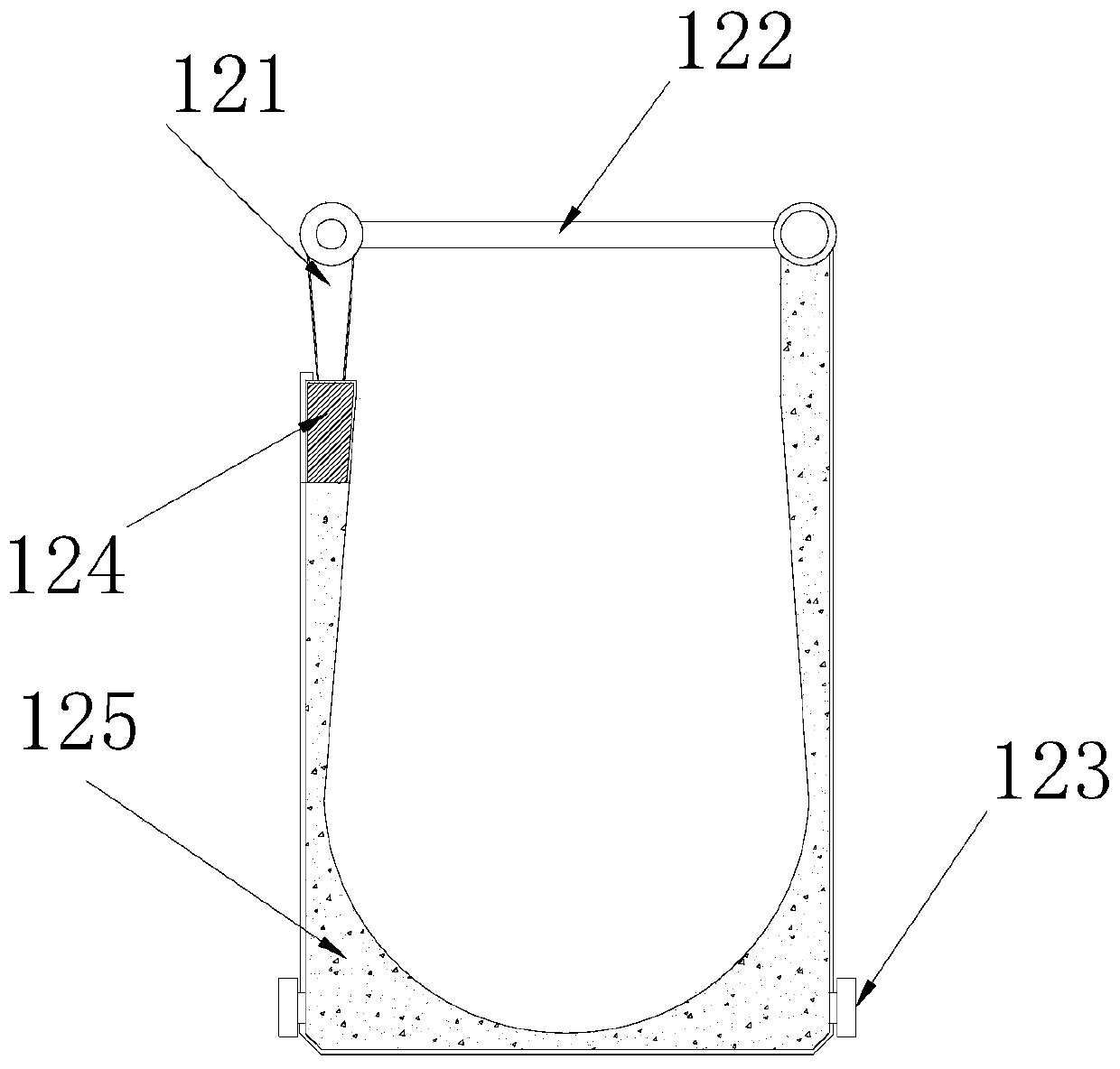

[0028] The present invention provides an environment-friendly multifunctional garbage recycling machine, the structure of which includes a recycling mechanism 1, a power supply base 2, and a display screen 3. The recycling mechanism 1 is embedded and installed on the upper end surface of the power supply The middle section of the upper side is welded to the lower end surface of the display screen 3, and the left and right sides of the display screen 3 are provided with a recovery mechanism 1; the recovery mechanism 1 includes a sleeve 11, a storage bucket 12, a connecting seat 13, and the sleeve 11 The storage bucket 12 is nested and connected to the outer end surface of the storage bucket 12. The storage bucket 12 is located directly above the connection seat 13. The connection seat 13 is embedded and installed directly below the sleeve 11 and connected to the power supply base 2. The connection between the left side ...

Embodiment 2

[0037] as attached Figure 6 To attach Figure 8 As shown: the sleeve 11 includes a limit block 111, a throwing port 112, a gate 113, an anti-collision strip 114, and a sliding rail 115, and the limit block 111 is embedded and installed on the inner left end surface of the sleeve 11. The throwing port 112 is embedded and engaged on the inner end surface of the sleeve 11, the gate 113 is movably engaged and installed on the outer end surface of the sleeve 11, and the anti-collision strip 114 is embedded and installed on the inner wall of the sleeve 11, and is located on the sliding Above the rail 115, the sliding rail 115 is located directly below the throwing opening 112, and the diameter of the limiting block 111 adopts an arc shape gradually increasing from right to left, and can be effectively connected with the movable closing block 121.

[0038] Wherein, the limiting block 111 includes an arc-shaped plate 11a, a diversion groove 11b, an intercepting block 11c, and an inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com