A kind of preparation method of corundum-zirconium mullite breathable brick with high thermal shock resistance

A technology of zirconium mullite and thermal shock resistance, which is applied in the field of preparation of high thermal shock resistance corundum-zirconium mullite breathable bricks, can solve the problems of unfavorable smelting operations, fracture damage, high porosity, etc., and achieve heat resistance Excellent peeling performance, simple and feasible process, high blowing success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

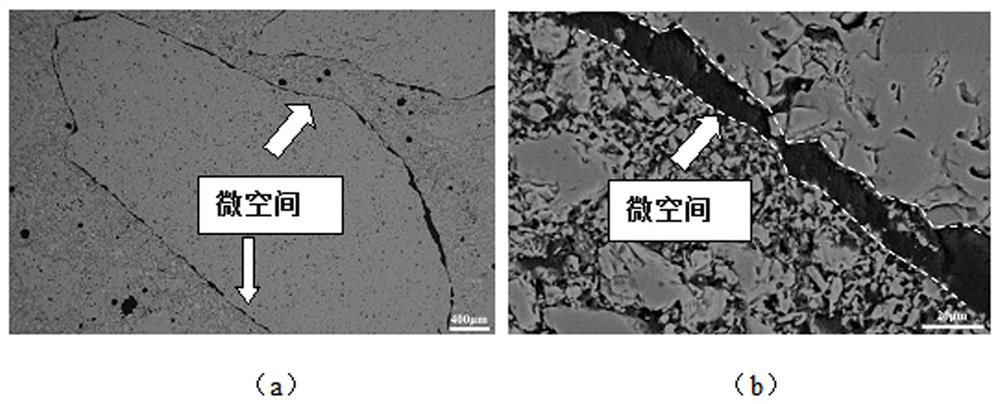

Image

Examples

Embodiment 1

[0025] Use absolute ethanol and phenolic resin solution to make a coating solution with a phenolic resin solution content of 40% according to the mass ratio of 60:40, respectively immerse 6-3mm and 3-1mm corundum particles in the resin solution, and use a filter screen to The particles are filtered out, and the solution is recovered and recycled; the filtered particles are placed in a tray and dried in an oven at 110°C for 10 hours to obtain coated corundum particles of 6-3mm and 3-1mm respectively. In parts by mass, put 8 parts of corundum powder, 8 parts of zirconium mullite powder, 5 parts of silica micropowder, 6 parts of alumina micropowder, 3 parts of hydrated alumina powder, and 0.2 parts of high-efficiency dispersant (additional) into a ball mill jar , and dry mixed evenly to obtain mixed powder A, which is ready for use; 30 parts of 6-3mm coated corundum particles, 25 parts of 3-1mm coated corundum particles, 5 parts of 1-0.5mm corundum particles, 10 parts of 0.5-0.09m...

Embodiment 2

[0029]Use absolute ethanol and phenolic resin to make a coating solution with a phenolic resin solution content of 30% according to the mass ratio of 70:30, completely immerse 6-3mm corundum particles in the resin solution, filter the particles out with a filter, and recover the solution Then use it again; put the filtered particles into a tray and dry them in an oven at 110°C for 16 hours to obtain 6-3mm coated corundum particles. In terms of parts by mass, put 9 parts of corundum powder, 8 parts of zirconium mullite powder, 4 parts of silica micropowder, 4 parts of alumina micropowder, 5 parts of hydrated alumina, and 0.3 parts of high-efficiency dispersant (additional) into a ball mill tank, Dry mix evenly to obtain mixed powder A, ready to use. Add 30 parts of 6-3mm coated corundum particles, 25 parts of 3-1mm corundum particles, 10 parts of 1-0.5mm corundum particles, 5 parts of 0.5-0.09mm zirconium mullite particles into the mixer and stir for 1-3min, then put Add the m...

Embodiment 3

[0033] Use absolute ethanol and phenolic resin solution to make a coating solution with a phenolic resin solution content of 70% according to the mass ratio of 30:70, respectively immerse 3-1mm and 1-0.5mm corundum particles in the coating solution completely, filter The particles are filtered out with a net, and the solution is recovered for reuse; the filtered particles are placed in a stainless steel tray and dried in an oven at 110°C for 12 hours to obtain coated corundum particles of 3-1mm and 1-0.5mm respectively. In terms of parts by mass, put 10 parts of corundum powder, 6 parts of zirconium mullite powder, 4 parts of silica micropowder, 8 parts of alumina micropowder, 2 parts of hydrated alumina, and 0.3 parts of high-efficiency dispersant (additional) into a ball mill jar, Dry mix evenly to obtain mixed powder A, ready to use. Add 30 parts of 6-3mm corundum particles, 25 parts of 3-1mm coated corundum particles, 10 parts of 1-0.5mm coated corundum particles, and 5 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com