Continuous production system and production method of polysiloxane

A technology of polysiloxane and production system, applied in the field of continuous production system of polysiloxane, can solve the problems of high viscosity, yellowing of cross-linking, insufficient stirring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

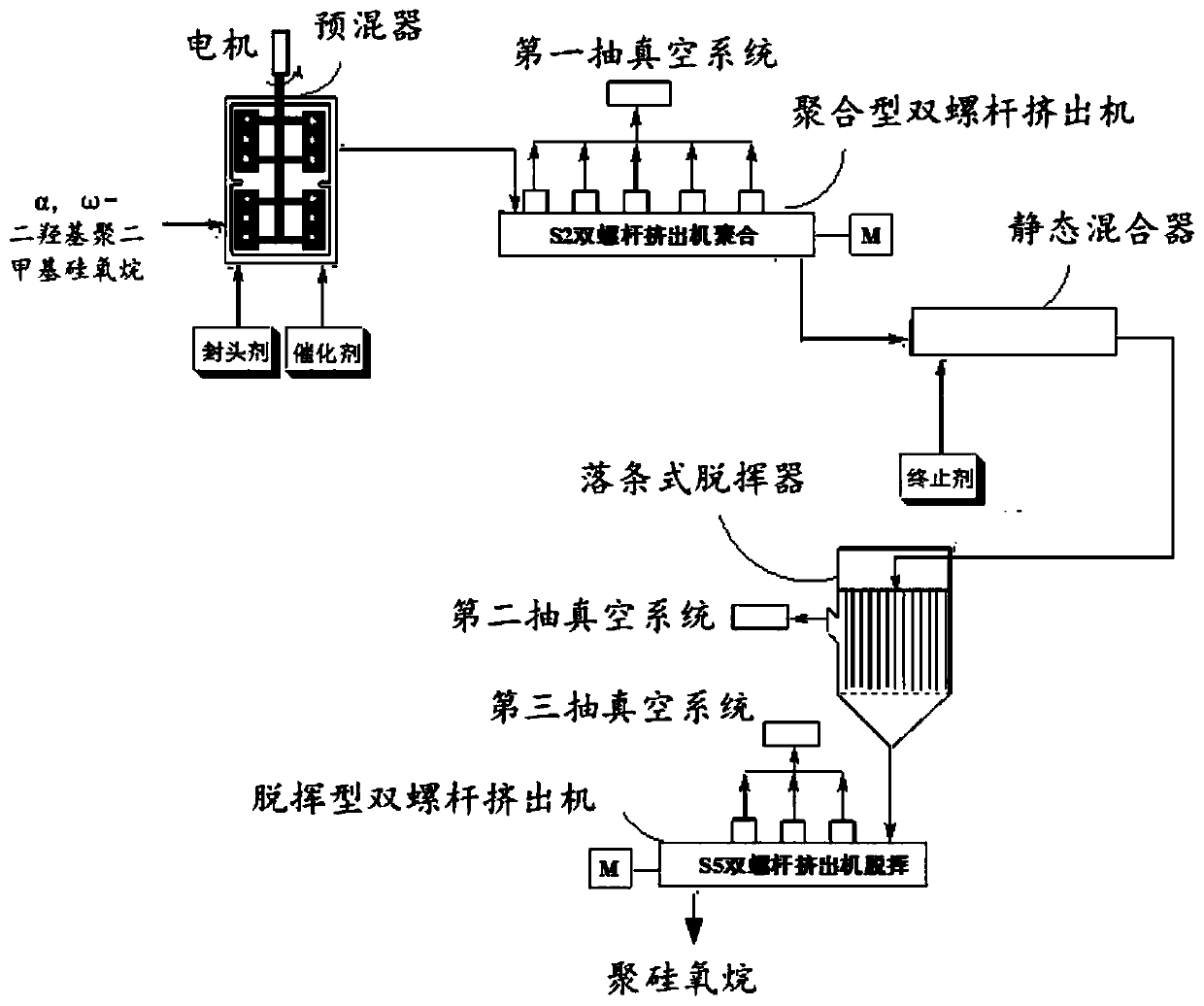

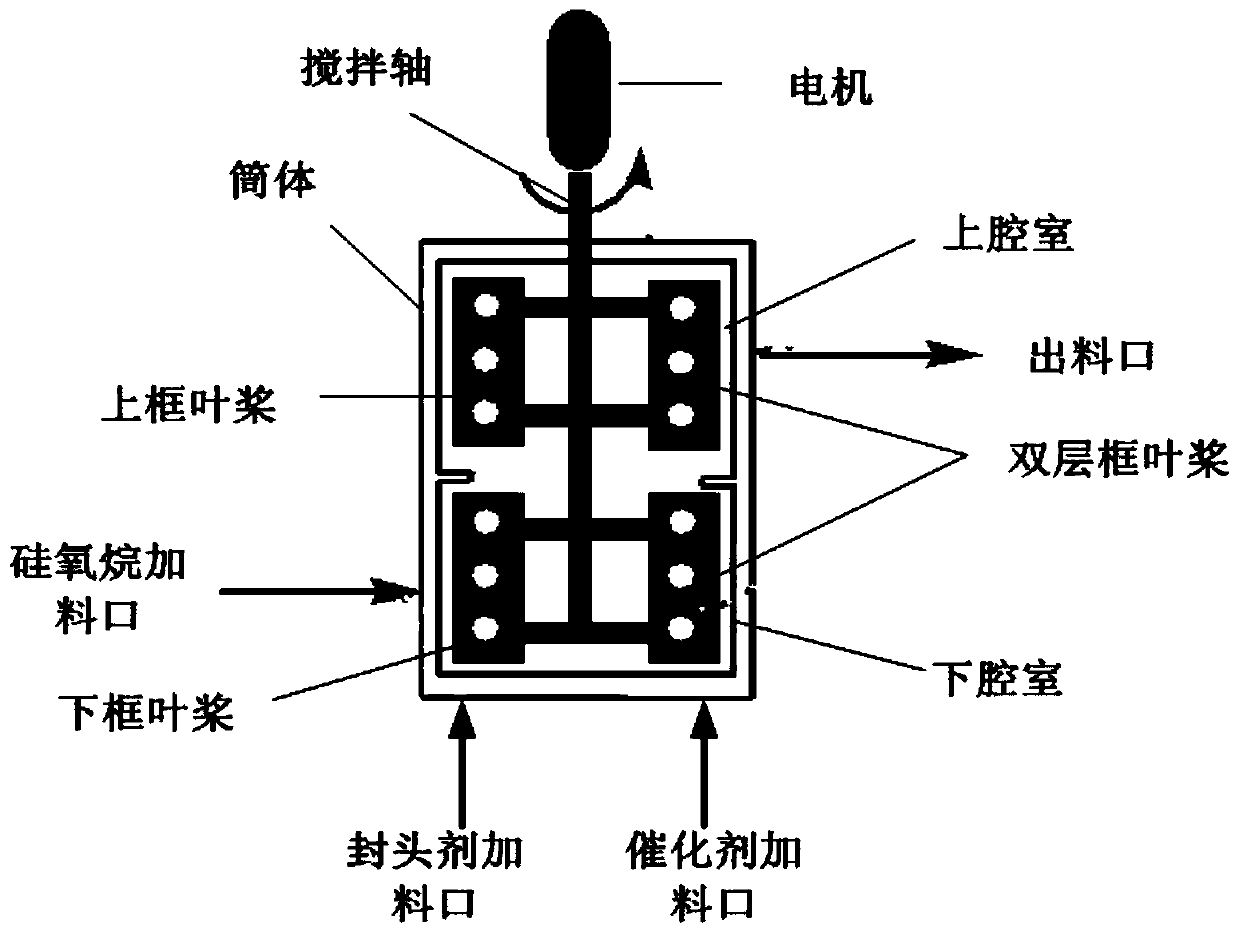

[0142] This embodiment provides a figure 1 The continuous production system of polysiloxane shown includes:

[0143] premixer;

[0144] A polymeric twin-screw extruder connected to the outlet of the premixer;

[0145] A first vacuum pump connected to the exhaust port of the polymeric twin-screw extruder;

[0146] A static mixer connected to the outlet of the polymerization type twin-screw extruder;

[0147] A drop strip type devolatilizer connected to the discharge port of the static mixer;

[0148] The second vacuum pump that links to each other with the vacuum port of described drop bar type devolatilizer;

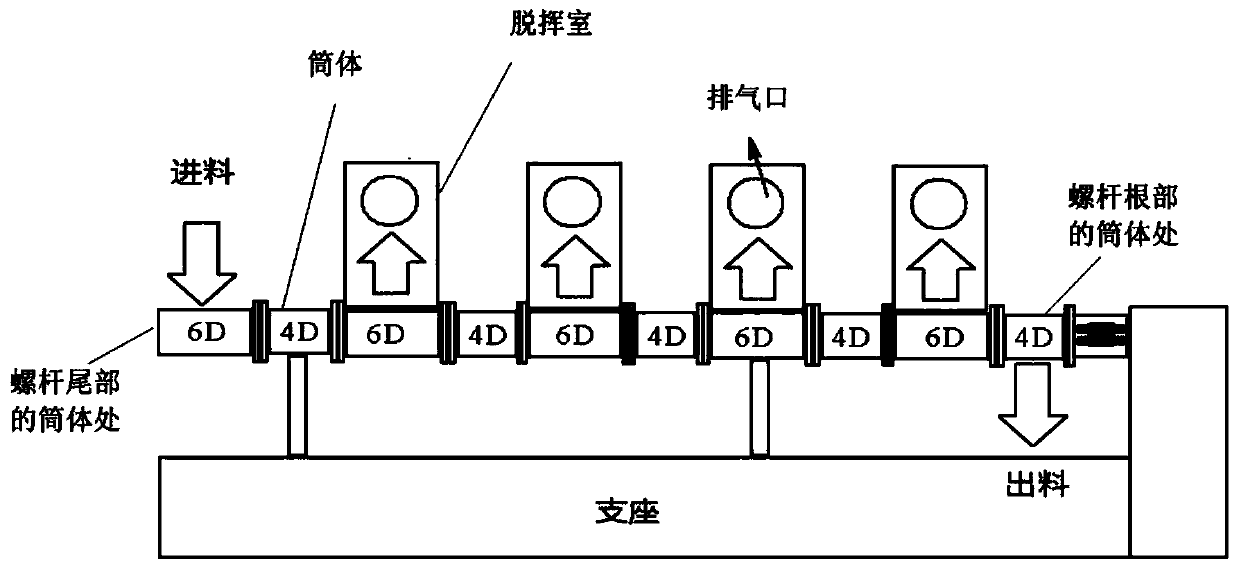

[0149] The devolatilization type twin-screw extruder that links to each other with the discharge port of described drop bar type devolatilizer;

[0150] The third vacuum pump connected with the vacuum port of the devolatilization type twin-screw extruder;

[0151] A cooling device connected to the outlet of the devolatilization type twin-screw extruder;

[0152] A...

Embodiment 2

[0180] This embodiment provides a figure 1 The continuous production system of polysiloxane shown includes:

[0181] premixer;

[0182] A polymeric twin-screw extruder connected to the outlet of the premixer;

[0183] A first vacuum pump connected to the exhaust port of the polymeric twin-screw extruder;

[0184] A static mixer connected to the outlet of the polymerization type twin-screw extruder;

[0185] A drop strip type devolatilizer connected to the discharge port of the static mixer;

[0186] The second vacuum pump that links to each other with the vacuum port of described drop bar type devolatilizer;

[0187] The devolatilization type twin-screw extruder that links to each other with the discharge port of described drop bar type devolatilizer;

[0188] The third vacuum pump connected with the vacuum port of the devolatilization type twin-screw extruder;

[0189] A cooling device connected to the outlet of the devolatilization type twin-screw extruder;

[0190]A ...

Embodiment 3

[0208] This embodiment provides a figure 1 The continuous production system of polysiloxane shown includes:

[0209] premixer;

[0210] A polymeric twin-screw extruder connected to the outlet of the premixer;

[0211] A first vacuum pump connected to the exhaust port of the polymeric twin-screw extruder;

[0212] A static mixer connected to the outlet of the polymerization type twin-screw extruder;

[0213] A drop strip type devolatilizer connected to the discharge port of the static mixer;

[0214] The second vacuum pump that links to each other with the vacuum port of described drop bar type devolatilizer;

[0215] The devolatilization type twin-screw extruder that links to each other with the discharge port of described drop bar type devolatilizer;

[0216] The third vacuum pump connected with the vacuum port of the devolatilization type twin-screw extruder;

[0217] A cooling device connected to the outlet of the devolatilization type twin-screw extruder;

[0218] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com