A continuous production system and production method of polysiloxane

A production system and technology of polysiloxane, which is applied in the field of continuous production system of polysiloxane, can solve problems such as high volatile content, insufficient stirring, and poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

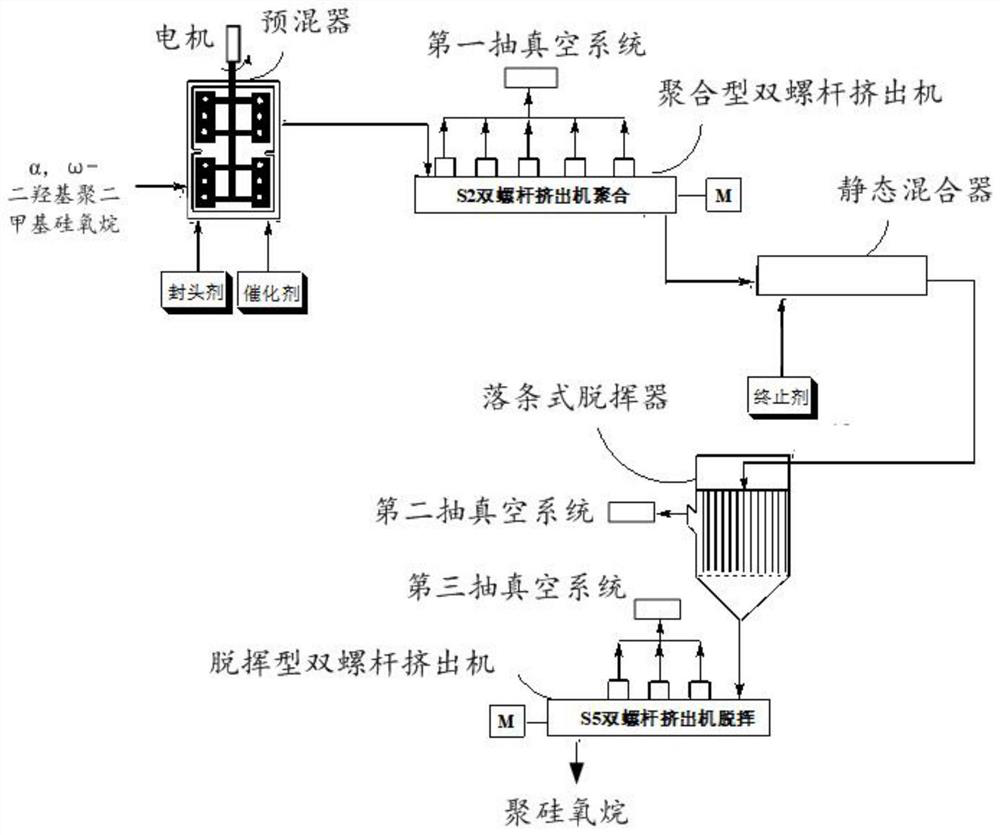

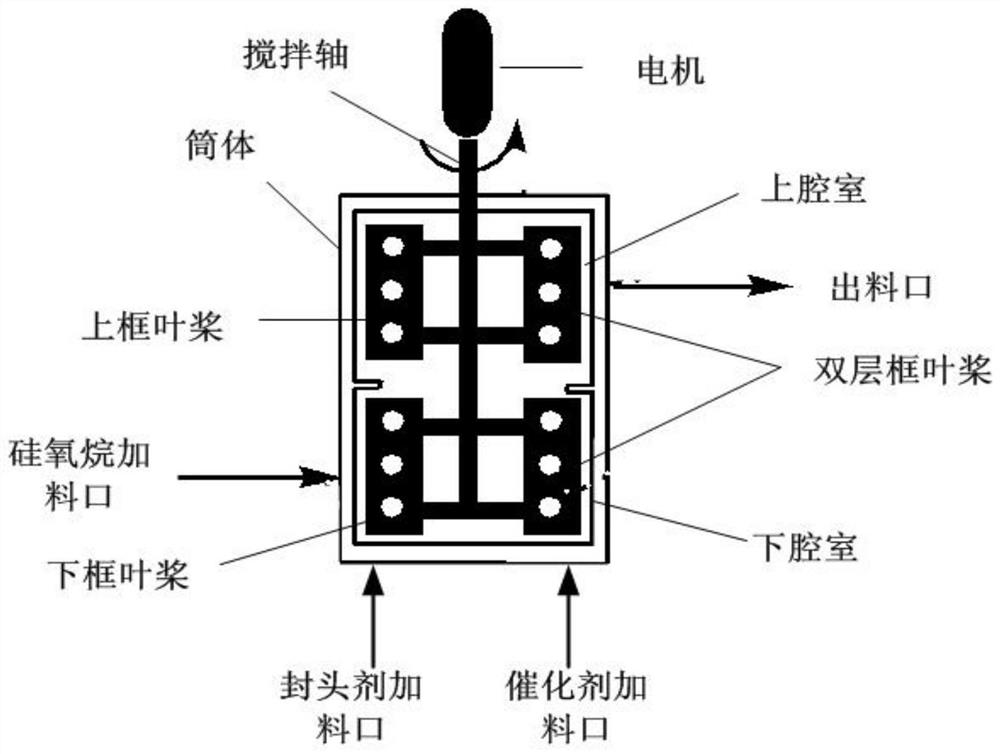

[0142] This embodiment provides a figure 1 The continuous production system of polysiloxane shown includes:

[0143] premixer;

[0144] A polymeric twin-screw extruder connected to the outlet of the premixer;

[0145] A first vacuum pump connected to the exhaust port of the polymeric twin-screw extruder;

[0146] A static mixer connected to the outlet of the polymerization type twin-screw extruder;

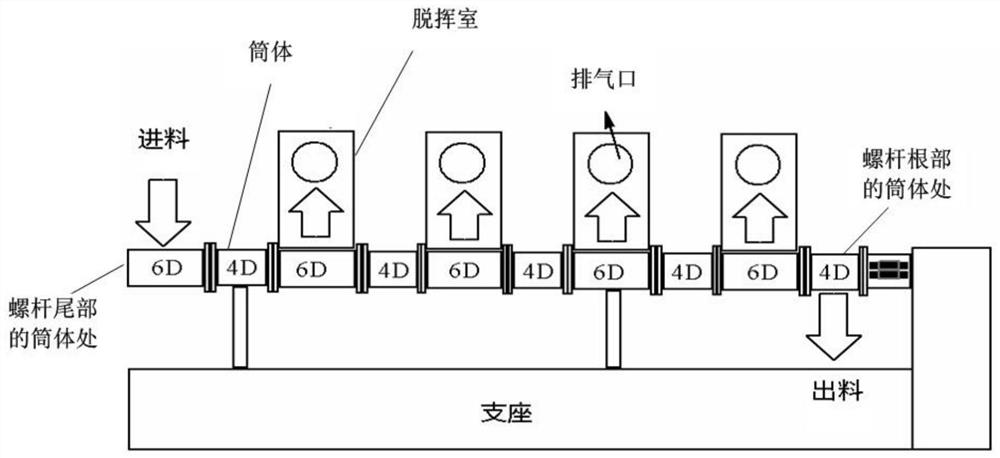

[0147] A drop strip type devolatilizer connected to the discharge port of the static mixer;

[0148] The second vacuum pump that links to each other with the vacuum port of described drop bar type devolatilizer;

[0149] The devolatilization type twin-screw extruder that links to each other with the discharge port of described drop bar type devolatilizer;

[0150] The third vacuum pump connected with the vacuum port of the devolatilization type twin-screw extruder;

[0151] A cooling device connected to the outlet of the devolatilization type twin-screw extruder;

[0152] A...

Embodiment 2

[0180] This embodiment provides a figure 1 The continuous production system of polysiloxane shown includes:

[0181] premixer;

[0182] A polymeric twin-screw extruder connected to the outlet of the premixer;

[0183] A first vacuum pump connected to the exhaust port of the polymeric twin-screw extruder;

[0184] A static mixer connected to the outlet of the polymerization type twin-screw extruder;

[0185] A drop strip type devolatilizer connected to the discharge port of the static mixer;

[0186] The second vacuum pump that links to each other with the vacuum port of described drop bar type devolatilizer;

[0187] The devolatilization type twin-screw extruder that links to each other with the discharge port of described drop bar type devolatilizer;

[0188] The third vacuum pump connected with the vacuum port of the devolatilization type twin-screw extruder;

[0189] A cooling device connected to the outlet of the devolatilization type twin-screw extruder;

[0190]A ...

Embodiment 3

[0208] This embodiment provides a figure 1 The continuous production system of polysiloxane shown includes:

[0209] premixer;

[0210] A polymeric twin-screw extruder connected to the outlet of the premixer;

[0211] A first vacuum pump connected to the exhaust port of the polymeric twin-screw extruder;

[0212] A static mixer connected to the outlet of the polymerization type twin-screw extruder;

[0213] A drop strip type devolatilizer connected to the discharge port of the static mixer;

[0214] The second vacuum pump that links to each other with the vacuum port of described drop bar type devolatilizer;

[0215] The devolatilization type twin-screw extruder that links to each other with the discharge port of described drop bar type devolatilizer;

[0216] The third vacuum pump connected with the vacuum port of the devolatilization type twin-screw extruder;

[0217] A cooling device connected to the outlet of the devolatilization type twin-screw extruder;

[0218] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com