Turbocharger

A technology for turbochargers and turbine housings, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., and can solve problems such as large impact force of the valve cover 16, unevenness on both sides, and impact on sealing, so as to avoid panting vibration, avoiding excessive idle time, and improving compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

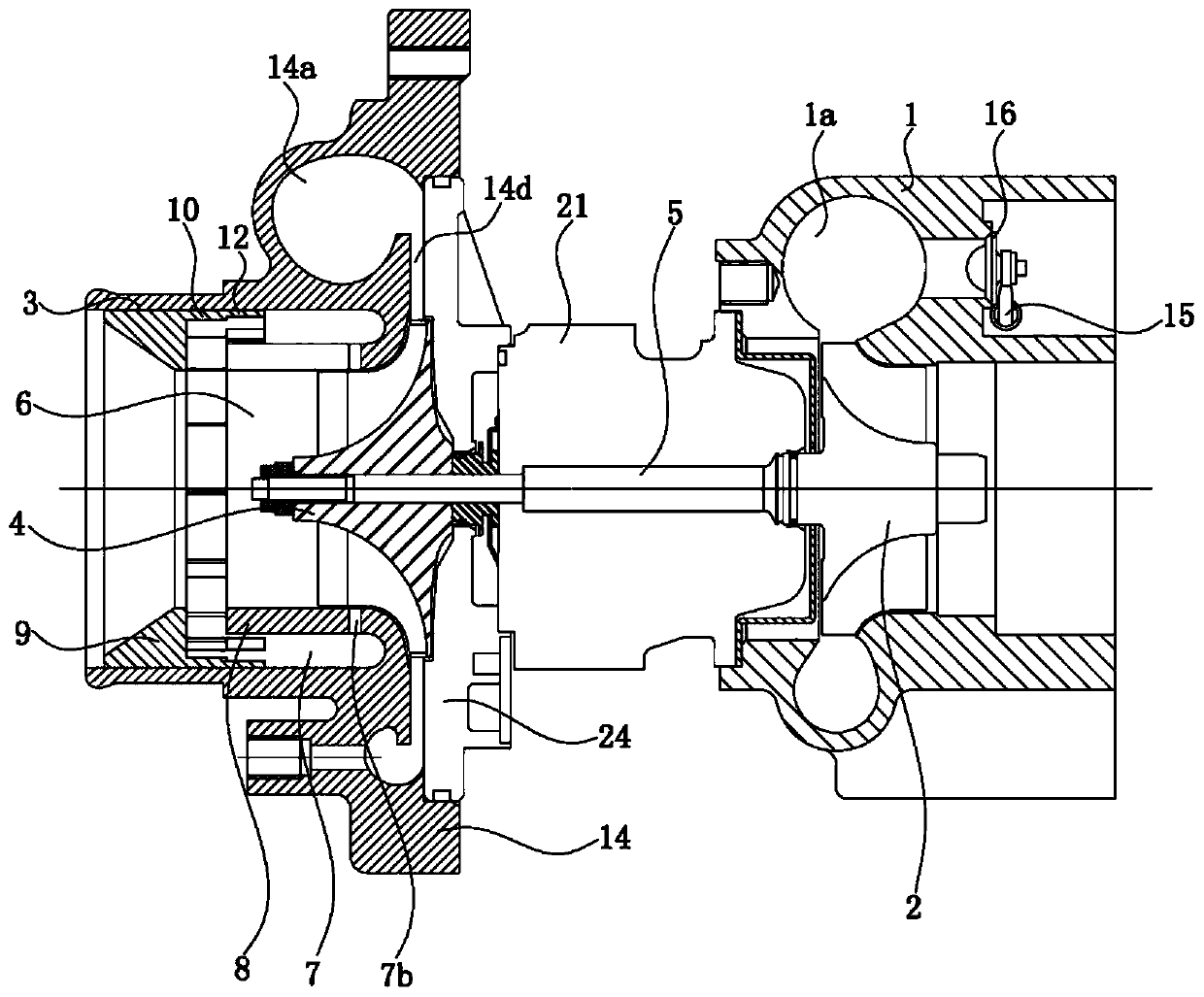

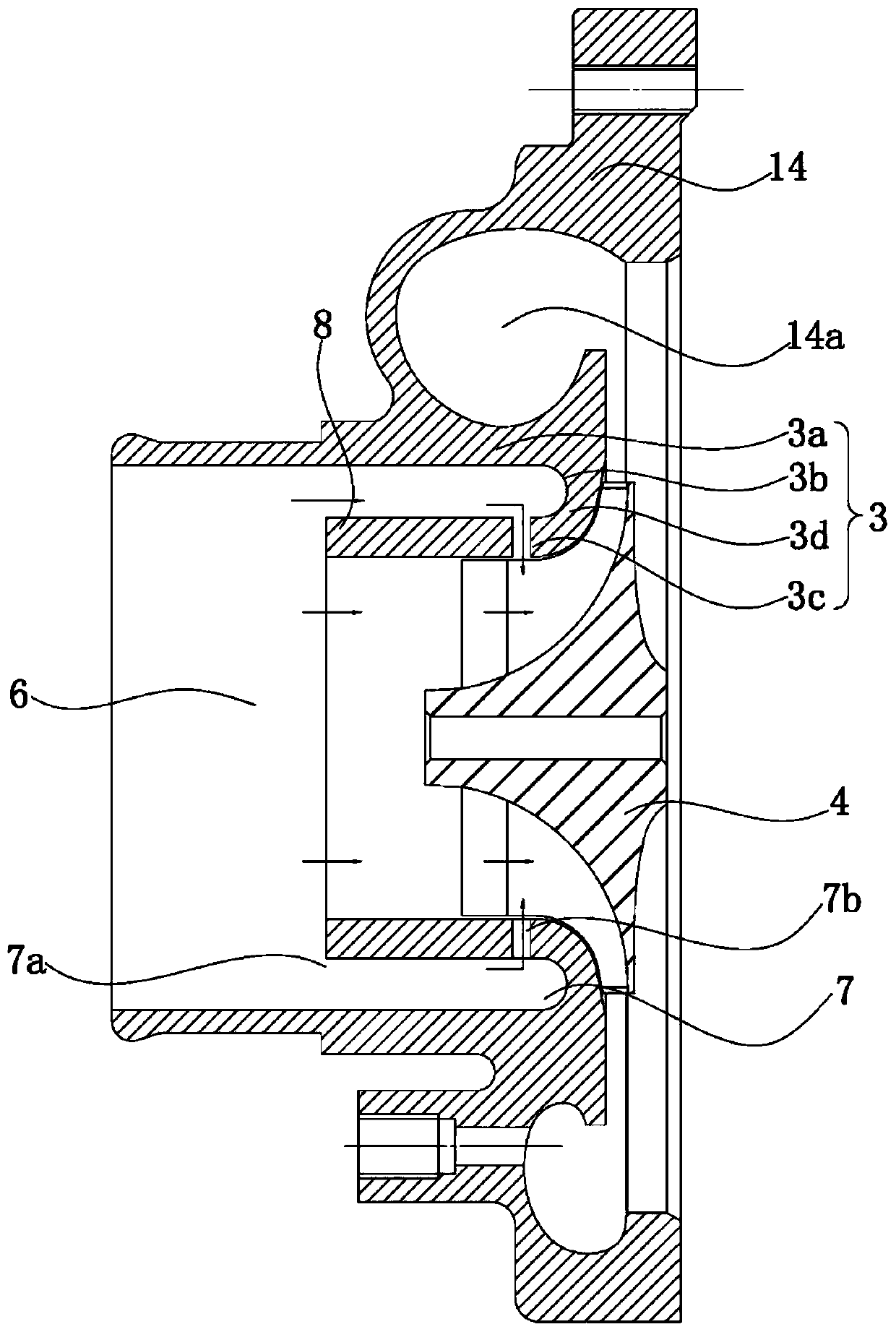

[0043] Such as figure 1 , the turbocharger of the present invention includes a turbine casing 1 with an exhaust gas passage 1a, a turbine impeller 2, a compressor casing, a compressor impeller 4, a rotating shaft 5, an intermediate casing 21, a shaft seal sleeve 26, and a first sealing ring 25 , the second sealing ring 27, the turbine casing 1 is fixed to one end of the middle casing, the compressor casing is fixed to the other end of the middle casing 21, the turbine impeller 2 is located in the exhaust gas channel 1a of the turbine casing 1 and fixed to the rotating shaft 5, The rotating shaft 5 passes through the middle shell, and the compressor impeller 4 is fixed to the rotating shaft 5 . The compressor housing includes a cylinder and a flow channel housing 14 fixed to the cylinder. The compressor housing also includes a diffuser back plate 24 , and the diffuser back plate 24 is fixed to the flow channel housing 14 .

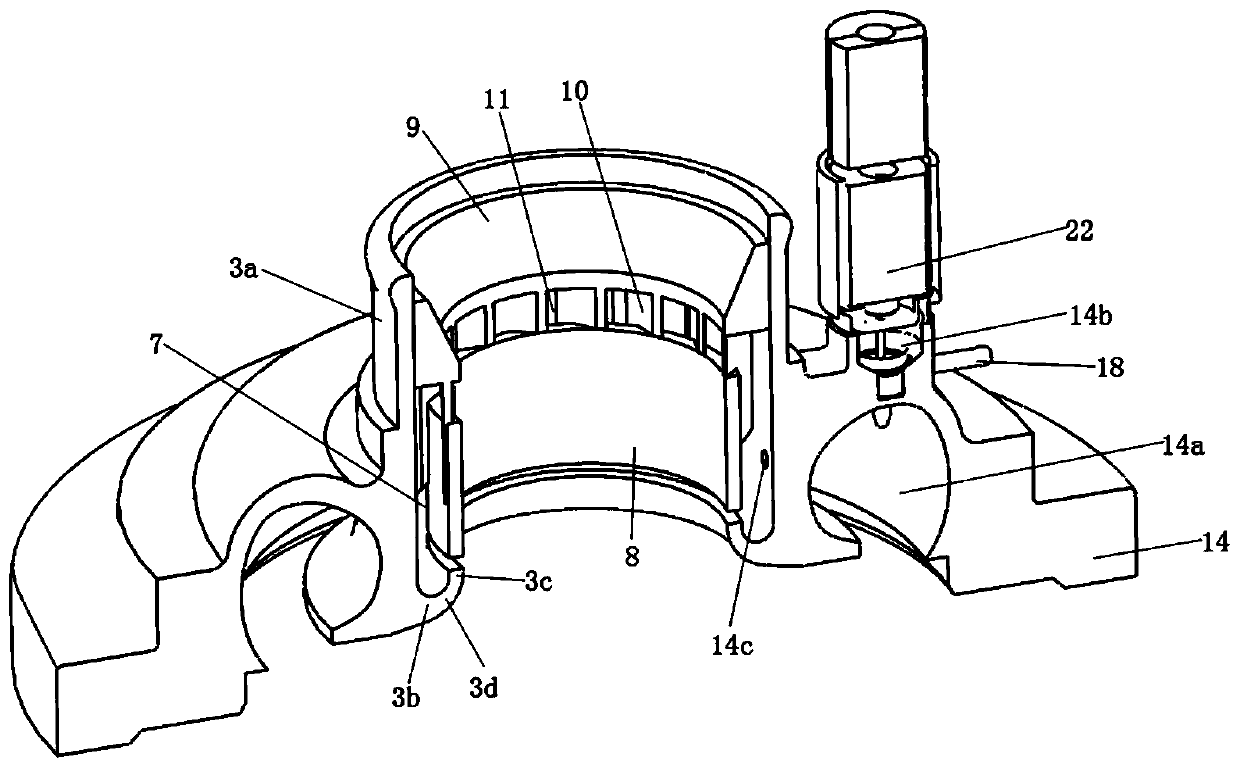

[0044] Such as figure 1 with figure 2 , The flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com