Intelligent centralized dry oil lubrication system suitable for drilling machine crown block

A lubrication system and crown block technology, which is applied in the direction of engine lubrication, lubrication parts, mechanical equipment, etc., can solve the problems that the amount of lubrication cannot meet the design requirements of equipment lubrication, the safety hazards of construction personnel will increase, and the drilling efficiency will be reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be specifically described below in conjunction with the accompanying drawings.

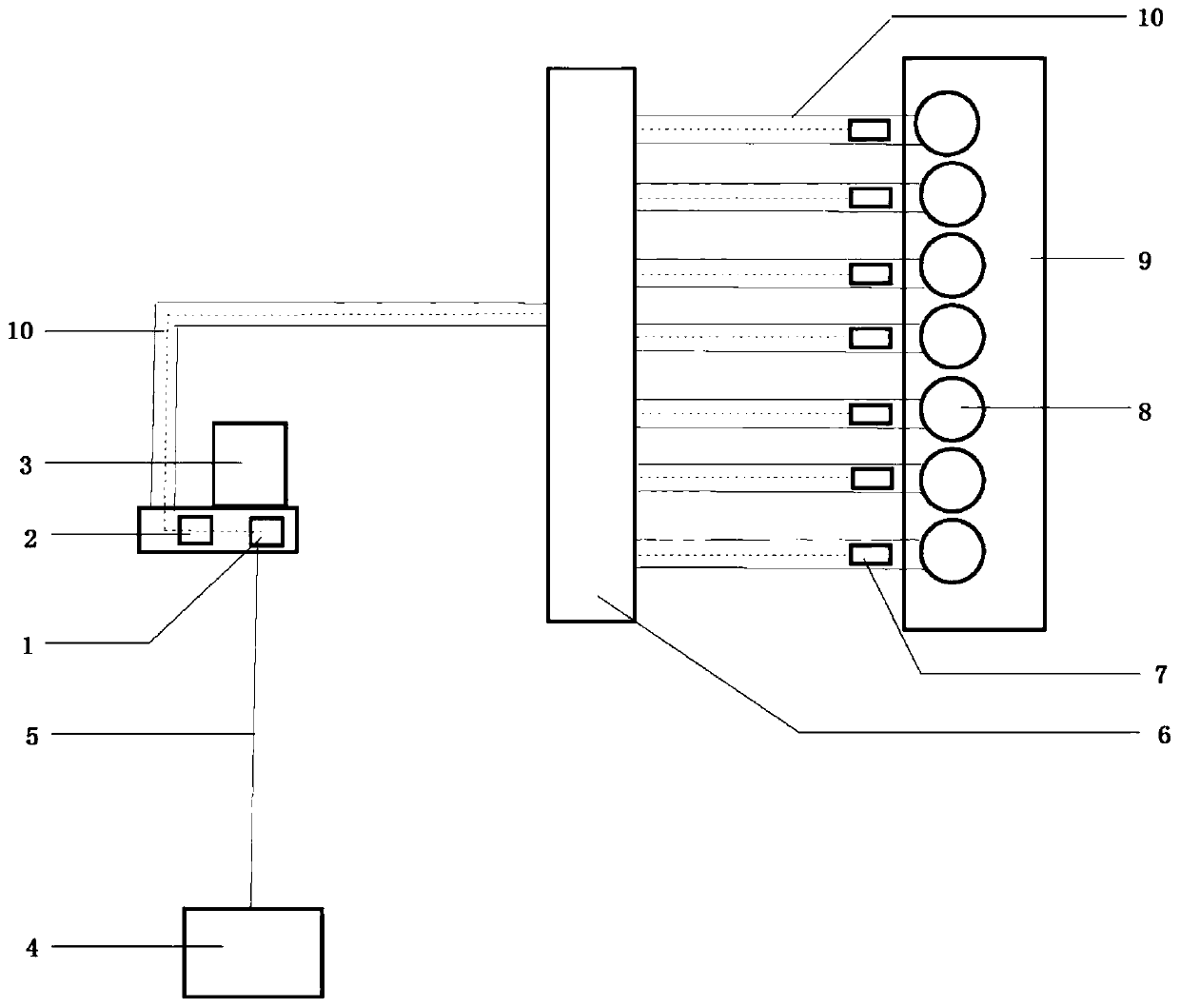

[0030] like figure 1 As shown, an intelligent centralized dry oil lubrication system suitable for drilling rig cranes is composed of PLC 1, plunger pump 2, oiler 6, sensor 7, and display 4, in which PLC 1 uses a microcomputer controller and a man-machine interface Set the dialogue-style Chinese menu to adjust various parameters. The plunger pump 2 adopts HR series electric high-pressure lubricating pump to deliver to the drilling rig crane 9 bearing 8 through the oil pipe 8 through the oiler 6. The oiler 6 uses an electromagnetic oiler to control the drilling rig Each bearing 8 on the crown block 9 is supplied with oil separately and integrated and placed centrally. The sensor 7 uses a high-sensitivity Hall sensor to detect the oil supply status of each bearing 8 on the crown block 9 of the drilling rig in real time, and feeds back the on-site information position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com