Time sequence control measuring device and method based on supersonic vortex structure

A timing control and supersonic technology, applied in the aerospace field, can solve the problems of inconsistent jet intensity and poor test repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

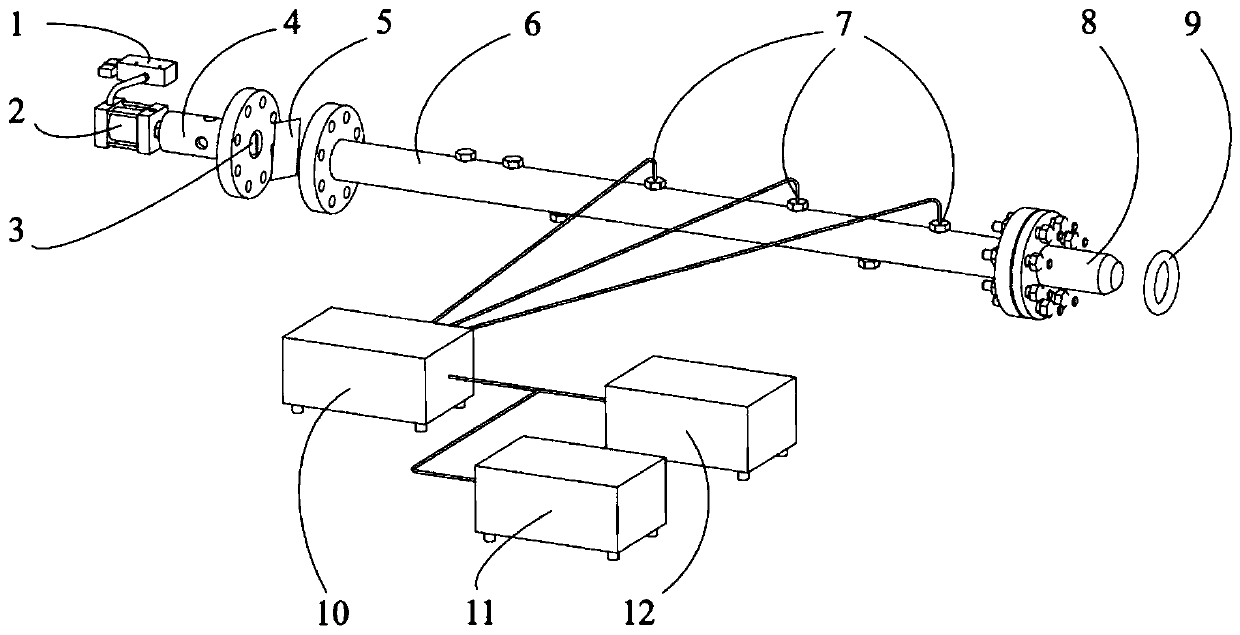

[0026] Such as figure 1 Shown is a generating device of a supersonic vortex structure related to this embodiment, including: a membrane breaking device, a supersonic vortex generating device and a measuring system.

[0027] The membrane rupture device includes: a solenoid valve 1, a single-acting cylinder 2, and a thimble 3 with a rectangular blade welded at the front end, wherein: the solenoid valve 1 is used to control the on-off of the gas circuit, and the source of the upstream gas circuit is provided by the gas source control panel. The downstream is connected to the single-acting cylinder 2, and the front end of the cylinder piston and the thimble 3 of the welded rectangular blade are fixed to each other by threads, and the solenoid valve 1 is controlled by a self-resetting button, and one click performs a membrane rupture action.

[0028] The thimble 3 is fixed on the piston rod by threading and applying thread glue, and cannot loosen or fall off during the expansion an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com