Automatic soldering machine teaching programming method based on model and numerical control drilling file

A programming method and automatic welding technology, applied in the direction of program control manipulator, manipulator, welding equipment, etc., can solve problems such as the inability to guarantee the consistency of coordinate values, affecting the accuracy of the correspondence between image coordinates and physical coordinates, and affecting the efficiency of teaching and programming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below in conjunction with the accompanying drawings.

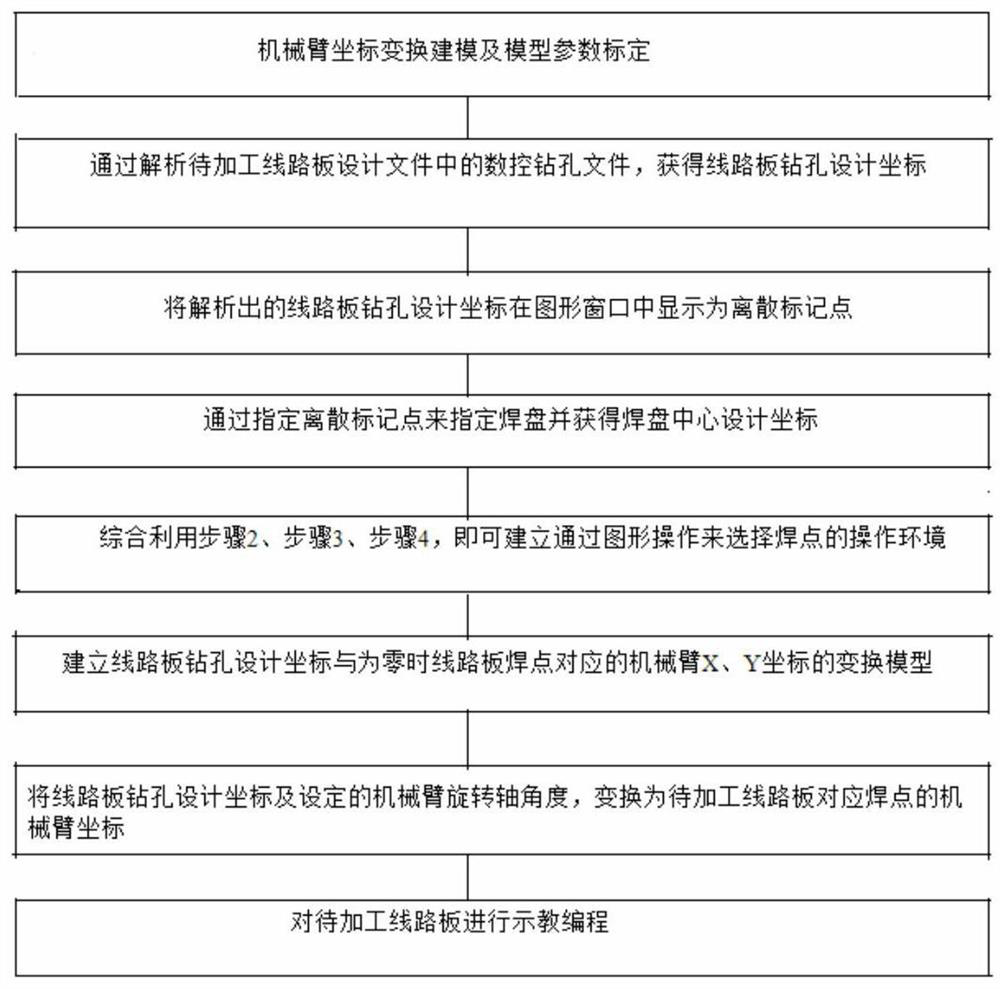

[0082] like figure 1 As shown in the figure, a teaching programming method for an automatic soldering machine based on a model and a CNC drilling file includes the following steps:

[0083] Step 1. Coordinate transformation modeling and model parameter calibration of the robotic arm, including the following sub-steps:

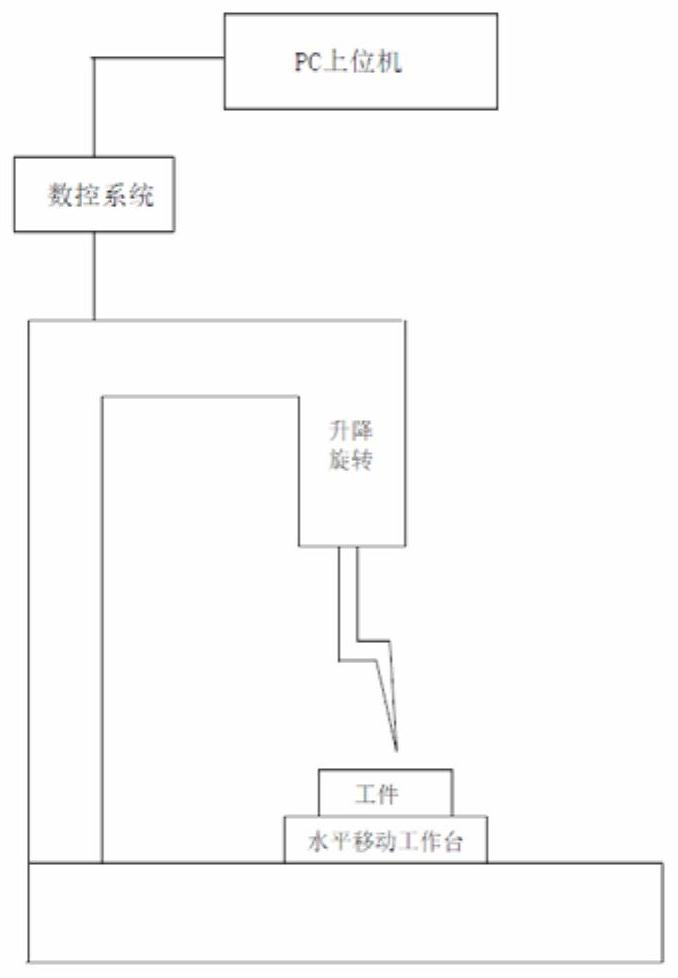

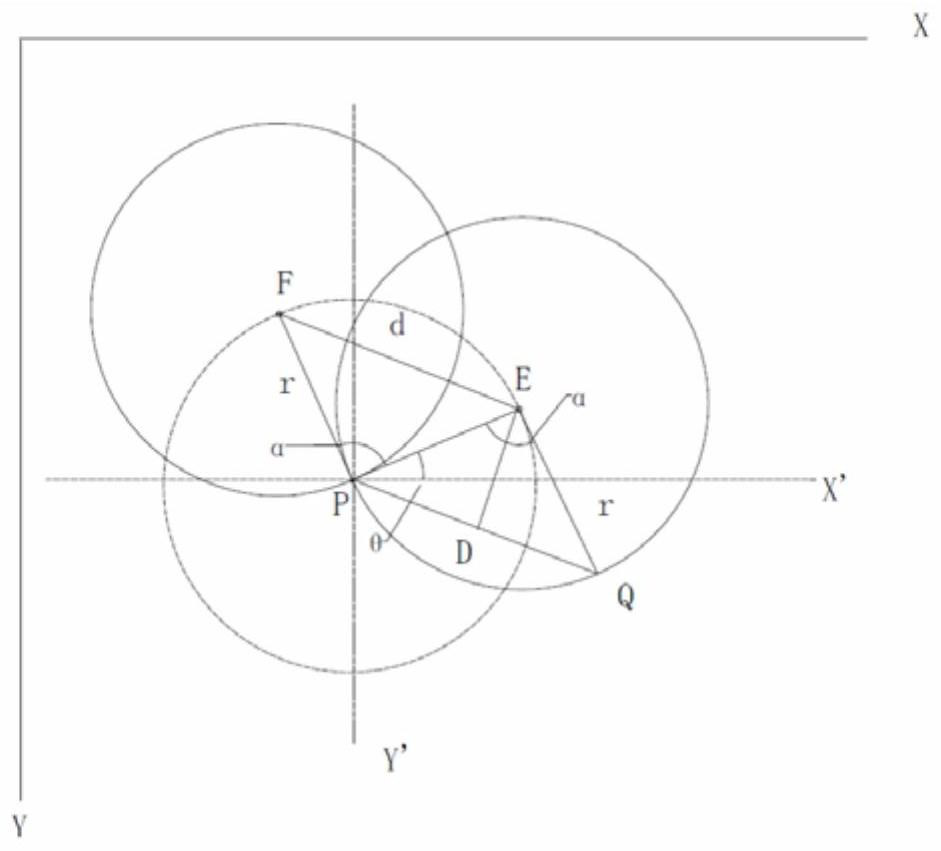

[0084] (a) Modeling of the coordinate transformation of the robotic arm. For an automatic soldering machine with a rotating axis, when the circuit board is fixed on the automatic soldering machine table by a fixture, the coordinate of the robotic arm corresponding to a solder joint on the circuit board is represented by (X , Y, Z, α) T , ie Cartesian coordinates (X, Y, Z) T Determined with the angle coordinate α of the rotation axis, the plane where the circuit board is located is parallel to the XY plane of the robot arm coordinate system through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com