Rock-soil thermal response test hole buried pipe backfilling and compactness detection processing method

A technology for thermal response testing and compactness testing, which is applied in the preparation of test samples, thermal development of materials, and detection of electromagnetic waves, etc. It can solve problems such as high cost-effectiveness ratio, achieve less disturbance, and ensure the effect of perforation orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below.

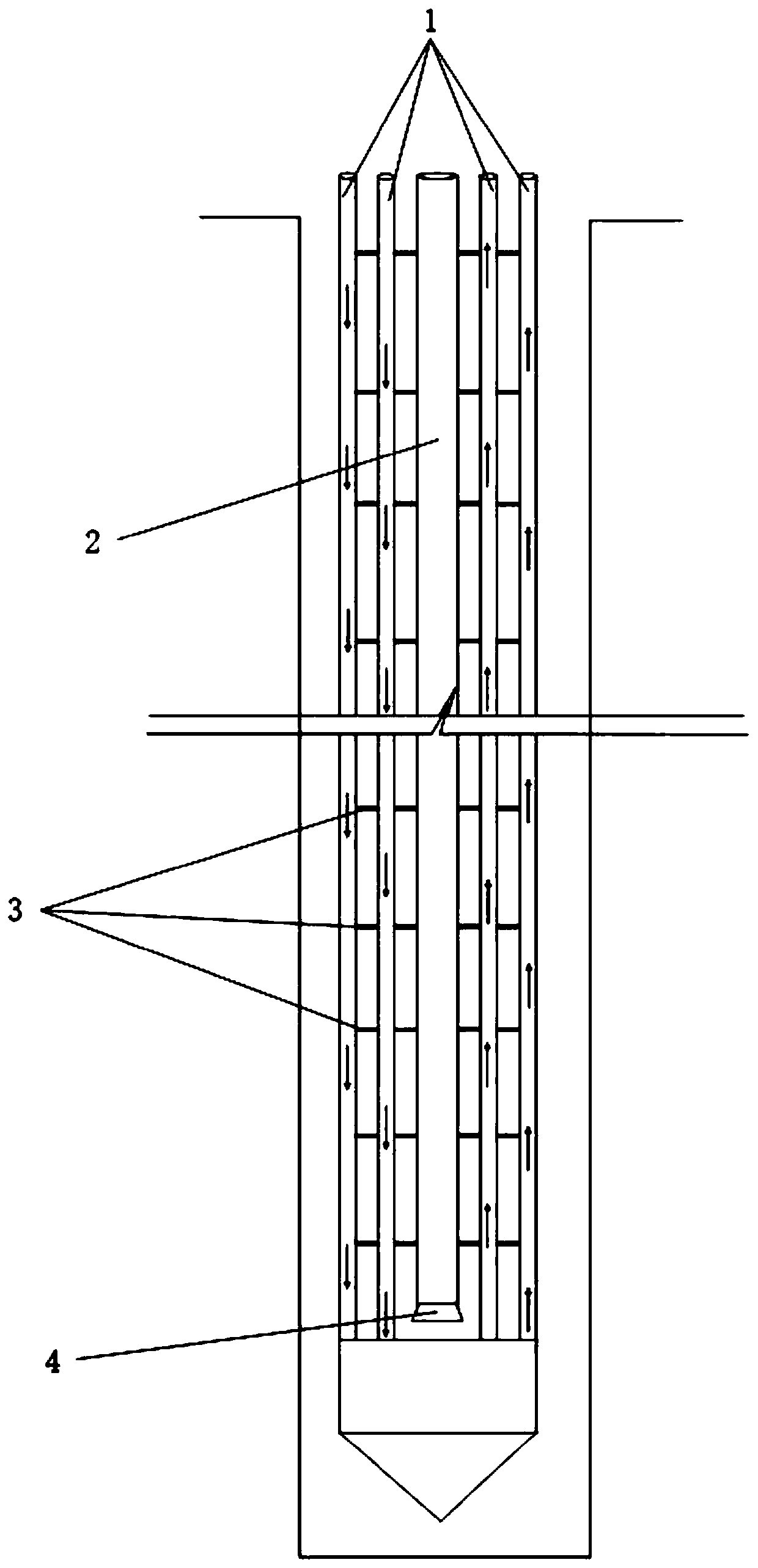

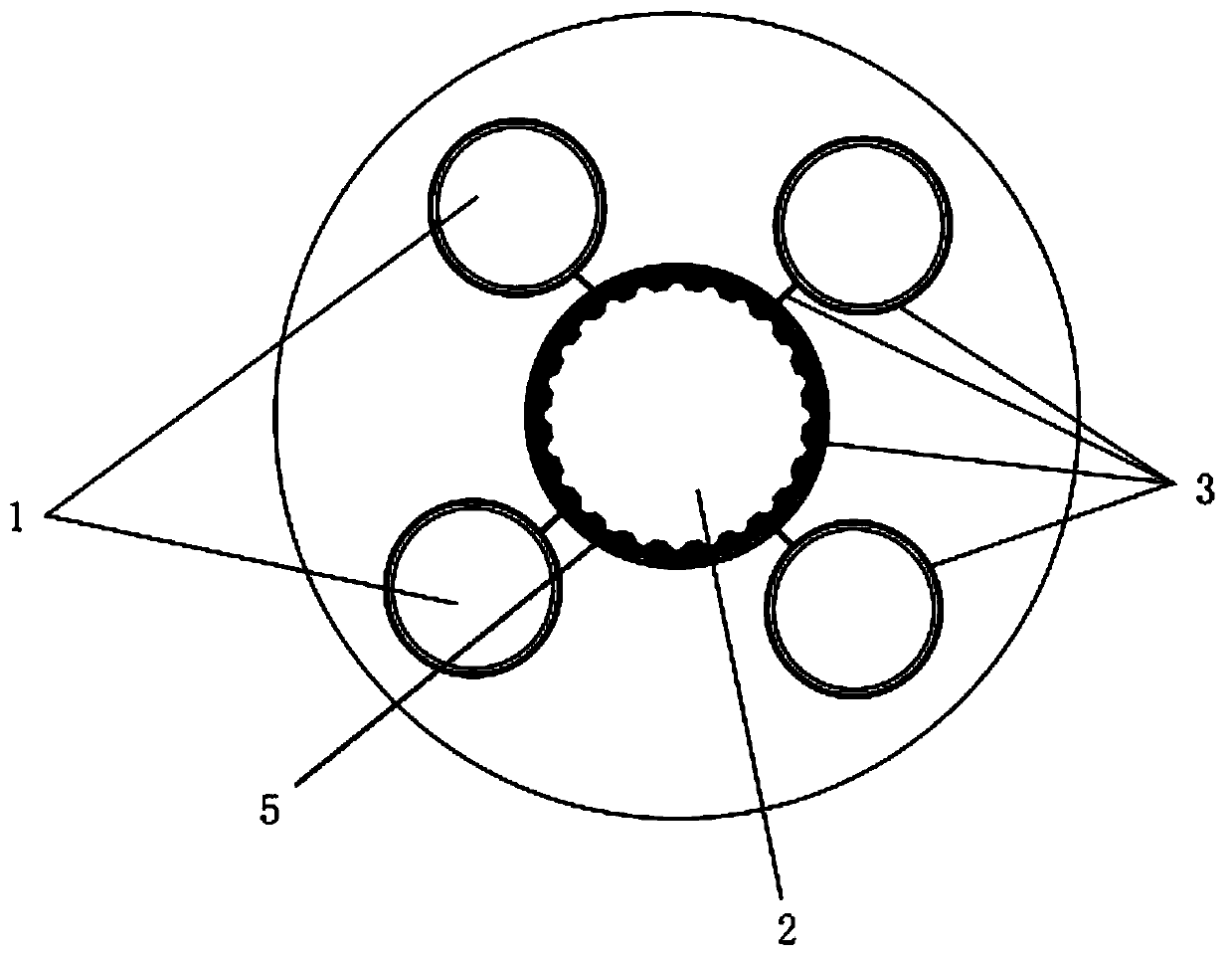

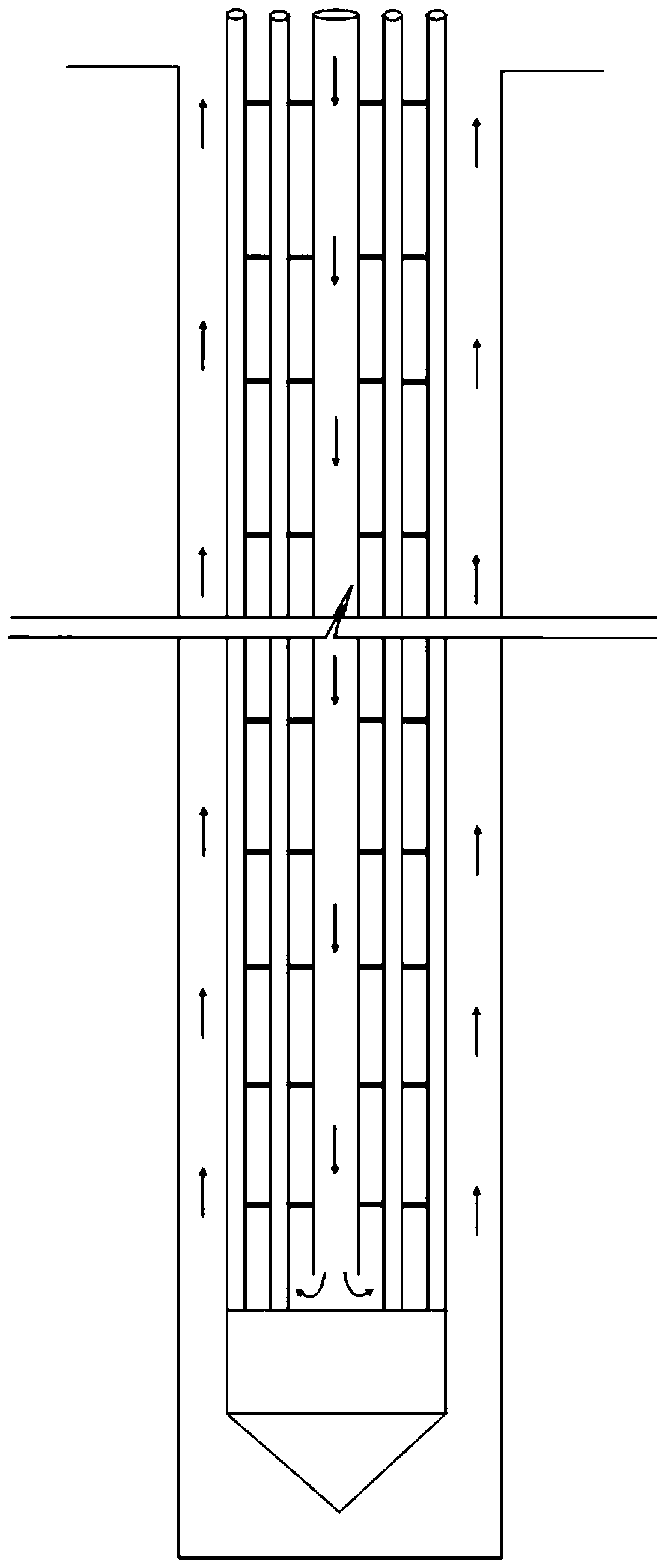

[0031] Such as Figure 1 to Figure 8 As shown, a method for backfilling and compaction detection and processing of buried pipes in geotechnical thermal response test holes, the basic equipment involved includes buried pipes 1, grouting pipes 2 and bracket cards 3, buried pipes 1 of the present invention are Double U-shaped pipe (the inlet and outlet of the U-shaped pipe are all upward), the grouting pipe 2 is arranged between the double U-shaped pipes, and the water inlet pipe and the outlet pipe of the grouting pipe 2 and the double U-shaped pipe are fixed with the bracket card 3, preferably One set every 3 meters to ensure its structural stability, the grouting pipe 2 is in the middle of the ascending pipe and the descending pipe of the underground pipe 1, and the lowest end of the grouting pipe 2 of the present invention is located above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com