Mini LED display panel and preparation method thereof

A technology for display panels and preparation steps, which is applied in the direction of electrical components, electric solid devices, circuits, etc., which can solve the problems of packaging difficulties, afterimages, and easy screen burn-in, and achieve the effects of reducing thickness, reducing manufacturing costs, and reducing manufacturing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

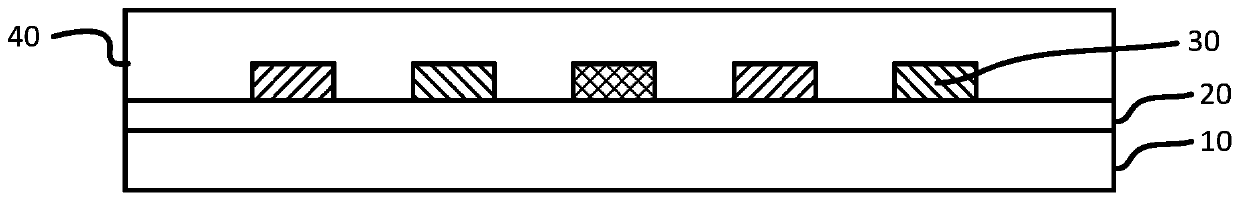

[0030] In this example, if figure 1 As shown, the mini LED display panel of the present invention includes a flexible layer 10 , a thin film transistor circuit 20 , a mini LED chip 30 and an encapsulation layer 40 .

[0031] The flexible layer 10 includes at least one of polydimethylsiloxane (PDMS, polydimethylsiloxane), polyimide film (Polyimide Film), flexible circuit board (Flexible Printed Circuit), and the flexible layer 10 has good flexibility, The mini LED display panel can be flexibly bent.

[0032] The thin film transistor circuit 20 is arranged on one side surface of the flexible layer 10. The thin film transistor circuit 20 includes several thin film transistor units, and the thin film transistor unit includes a P-type low-temperature polysilicon thin film transistor or an N-type low-temperature polysilicon thin film transistor. The thin film transistor circuit 20 includes a A plurality of scanning lines extending in the row direction, a plurality of single-ended s...

Embodiment 2

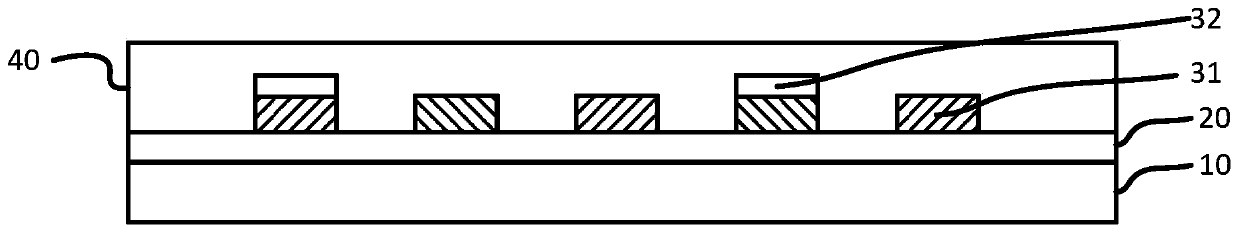

[0047] In this example, if figure 2 As shown, the mini LED display panel of the present invention includes a flexible layer 10 , a thin film transistor circuit 20 , a mini LED chip 31 and an encapsulation layer 40 .

[0048] The flexible layer 10 includes at least one of polydimethylsiloxane (PDMS, polydimethylsiloxane), polyimide film (PolyimideFilm), flexible circuit board (Flexible Printed Circuit), the flexible layer 10 has good flexibility, can The mini LED display panel realizes flexible bending.

[0049] The thin film transistor circuit 20 is arranged on one side surface of the flexible layer 10. The thin film transistor circuit 20 includes several thin film transistor units, and the thin film transistor unit includes a P-type low-temperature polysilicon thin film transistor or an N-type low-temperature polysilicon thin film transistor. The thin film transistor circuit 20 includes a A plurality of scanning lines extending in the row direction, a plurality of single-en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com