Predictive torque control method for dual motor drive system based on voltage vector preselection

A dual-motor drive, voltage vector technology, applied in the direction of multiple motor speed/torque control, motor generator control, electronic commutation motor control, etc., can solve the problem of increased system loss, phase current distortion, and system zero-sequence current It can reduce the pulsation, suppress the zero-sequence current, and reduce the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0136] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

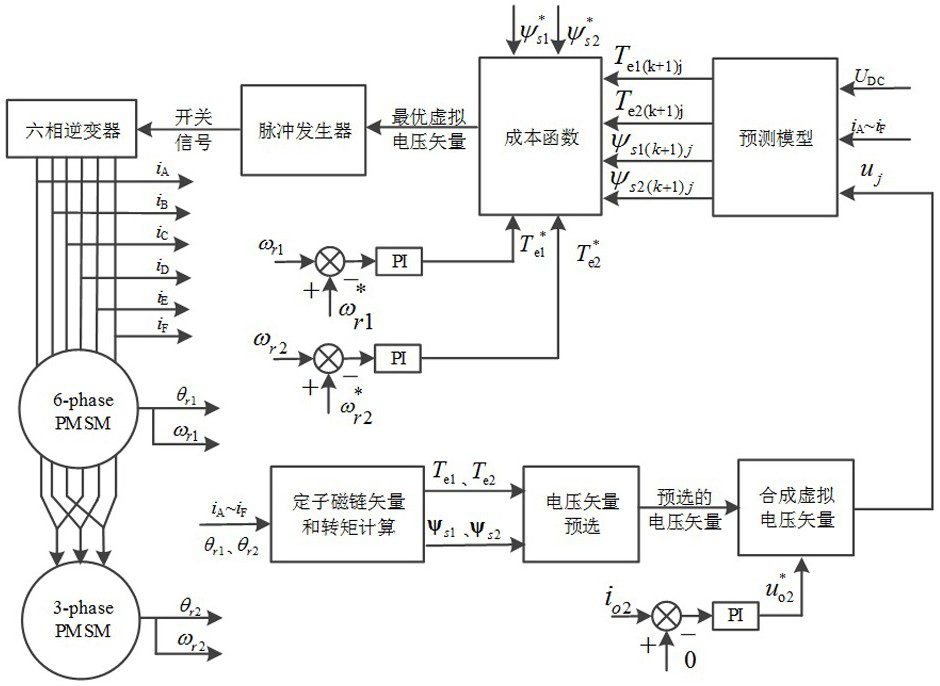

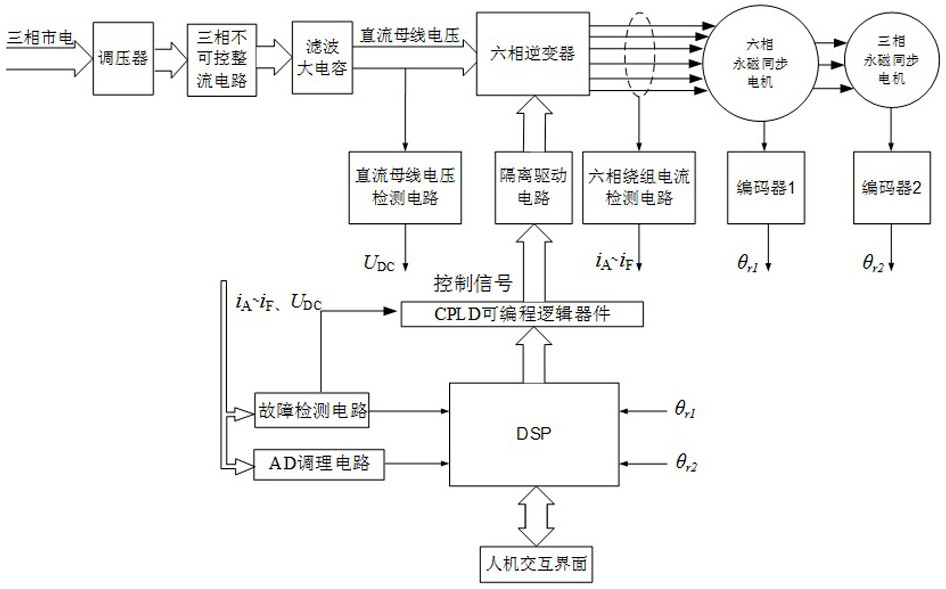

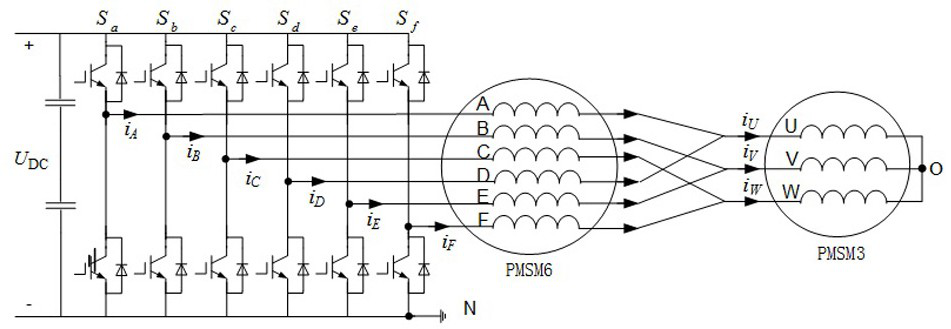

[0137]The present invention proposes a dual-motor drive system predictive torque control method based on voltage vector pre-selection. The purpose has three aspects: one is to realize the precise control of the torque and stator flux amplitude of two PMSMs; the other is to realize the effective control of zero-sequence current The third is to reduce the calculation amount of predictive torque control algorithm. According to the six-phase current obtained by sampling, the torque and stator flux amplitude of two PMSMs are calculated, and compared with the given value, it is judged whether the torque and stator flux amplitude of the two PMSMs need to be increased or decreased, and then according to In the sectors where the stator flux vectors of the two PMSMs are located, 9-11 voltage vectors are preselected to control the two PMSMs. The ze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com