Light-splitting stereoscopic vision device for detecting interior of high-temperature narrow cavity

A stereoscopic vision and spectroscopic technology, which is applied to TVs, color TVs, components of color TVs, etc., can solve the problems of difficult to meet the measurement environment parameters, unable to adapt to detection, limited viewing angle, etc. The effect of wide viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

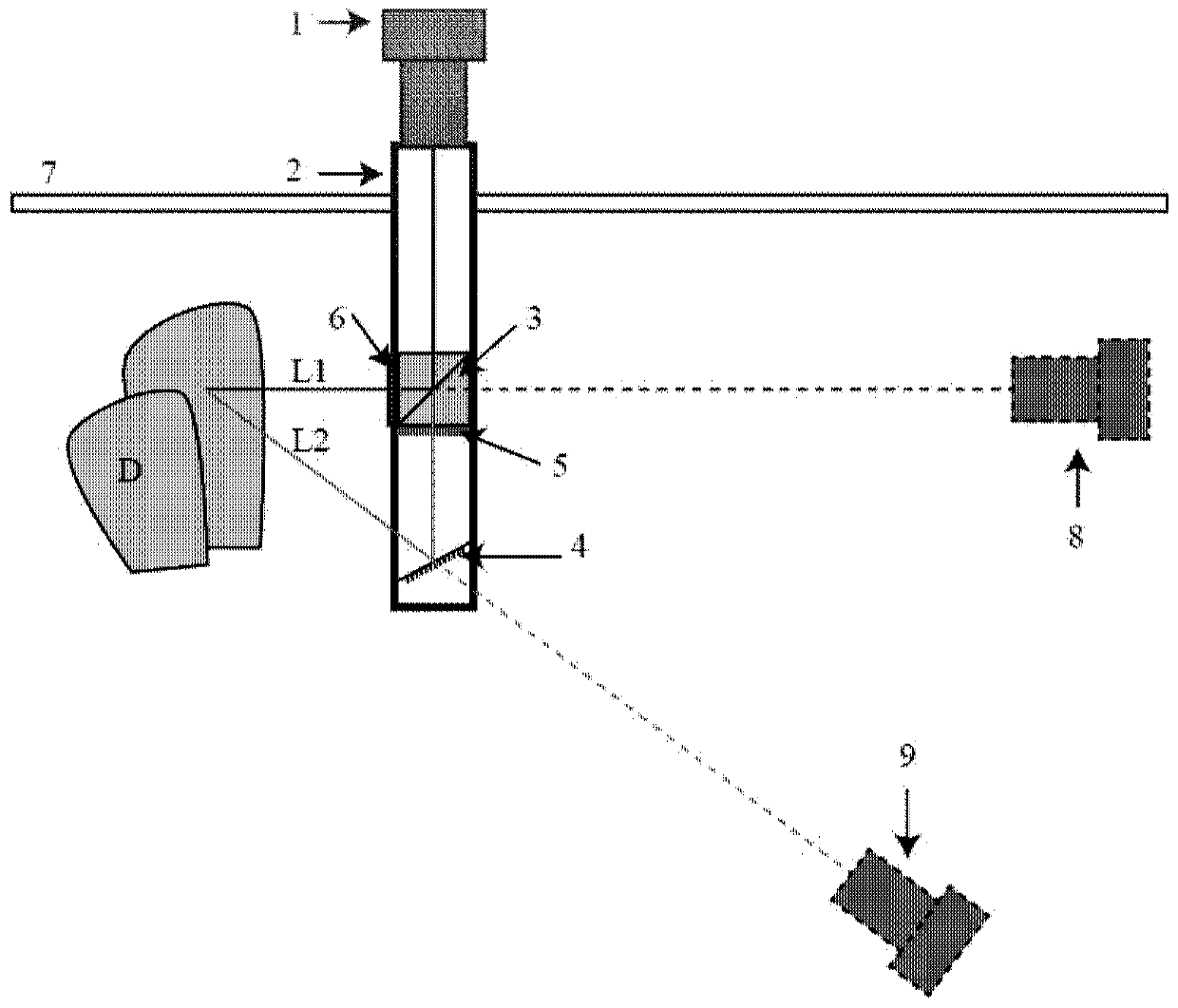

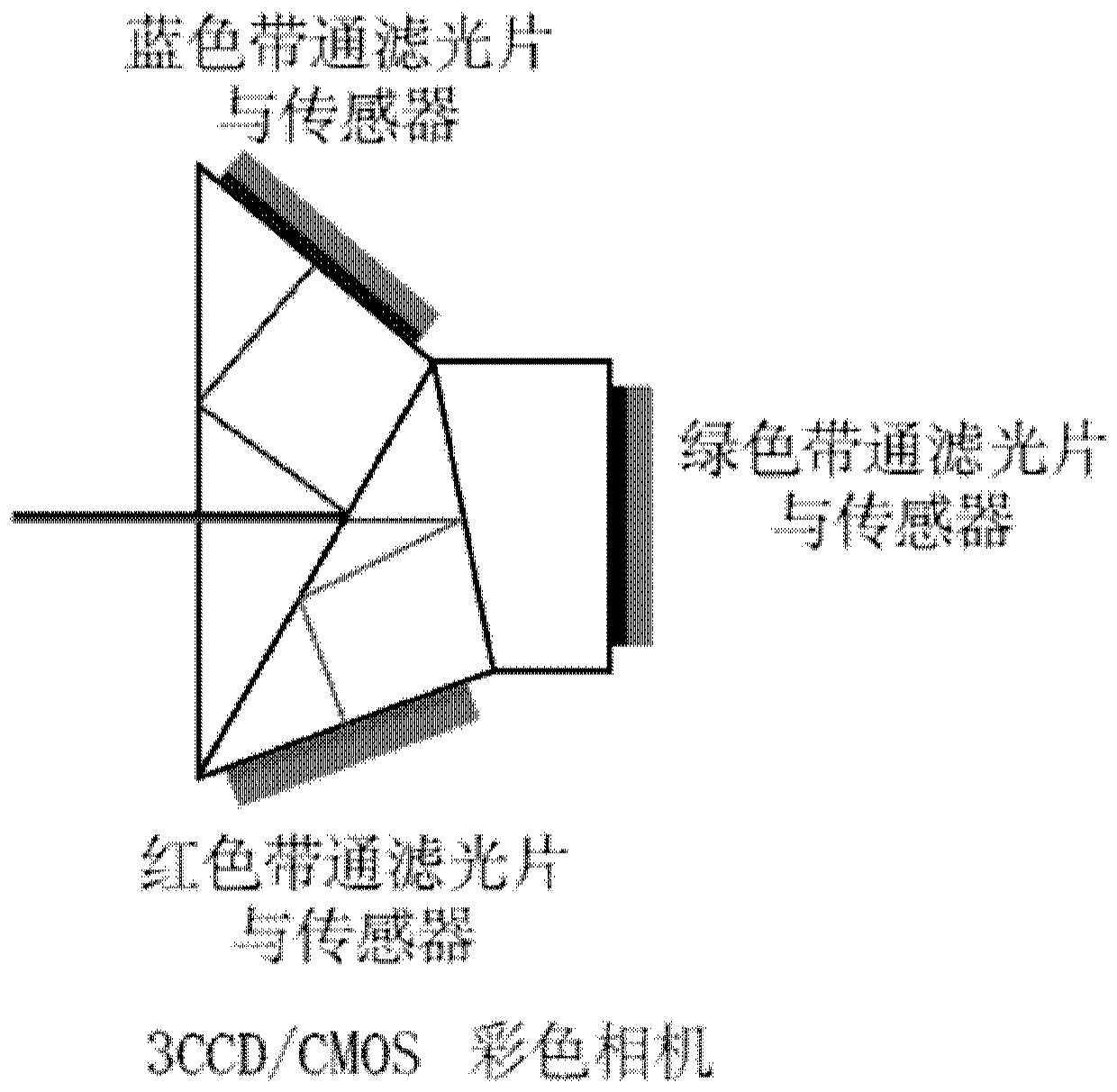

[0037] Embed the high temperature optical mirror barrel in the system into the interface 7 of the high temperature container. There is D object to be measured inside the high temperature container. The color spectroscopic imaging part 1 is set outside the high-temperature narrow cavity; the high-temperature optical lens barrel 2 is set inside the high-temperature narrow cavity. A color chip 5 and a blue spectrum color filter 6, wherein the light of the real image of the object is reflected by the above-mentioned reflector 4, then filtered by the above-mentioned red spectrum color filter 5, passes through the above-mentioned semi-transparent mirror 3, and then enters the above-mentioned color camera 1 Imaging: the light reflected by the object is filtered by the above-mentioned blue spectrum filter 6, and then reflected by the above-mentioned reflector 3, and enters the above-mentioned color camera 1 for imaging. Through the first and second pictures of different viewing angle...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is that a group of color cameras, half-transparent mirrors, red spectral filters and blue spectral filters are added above the interface of the high-temperature container to form a dual-camera spectroscopic stereoscopic device , whose structure is shown in the Figure 4 shown.

[0041] The above-mentioned spectroscopic stereoscopic vision device can be used for detection of objects inside the aero-engine, etc., and it is applied to the three-dimensional side view schematic diagram of the aero-engine as shown in Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com