Sand cleaning treatment system for castings

A processing system and sand cleaning technology, applied in the directions of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of sand particles easily adhering to the surface of castings, destroying the quality of casting products, affecting the effect of sand cleaning of castings, etc., to prevent Sand and dust adhere to the surface of the workpiece, improve the sand cleaning effect and efficiency, and the effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

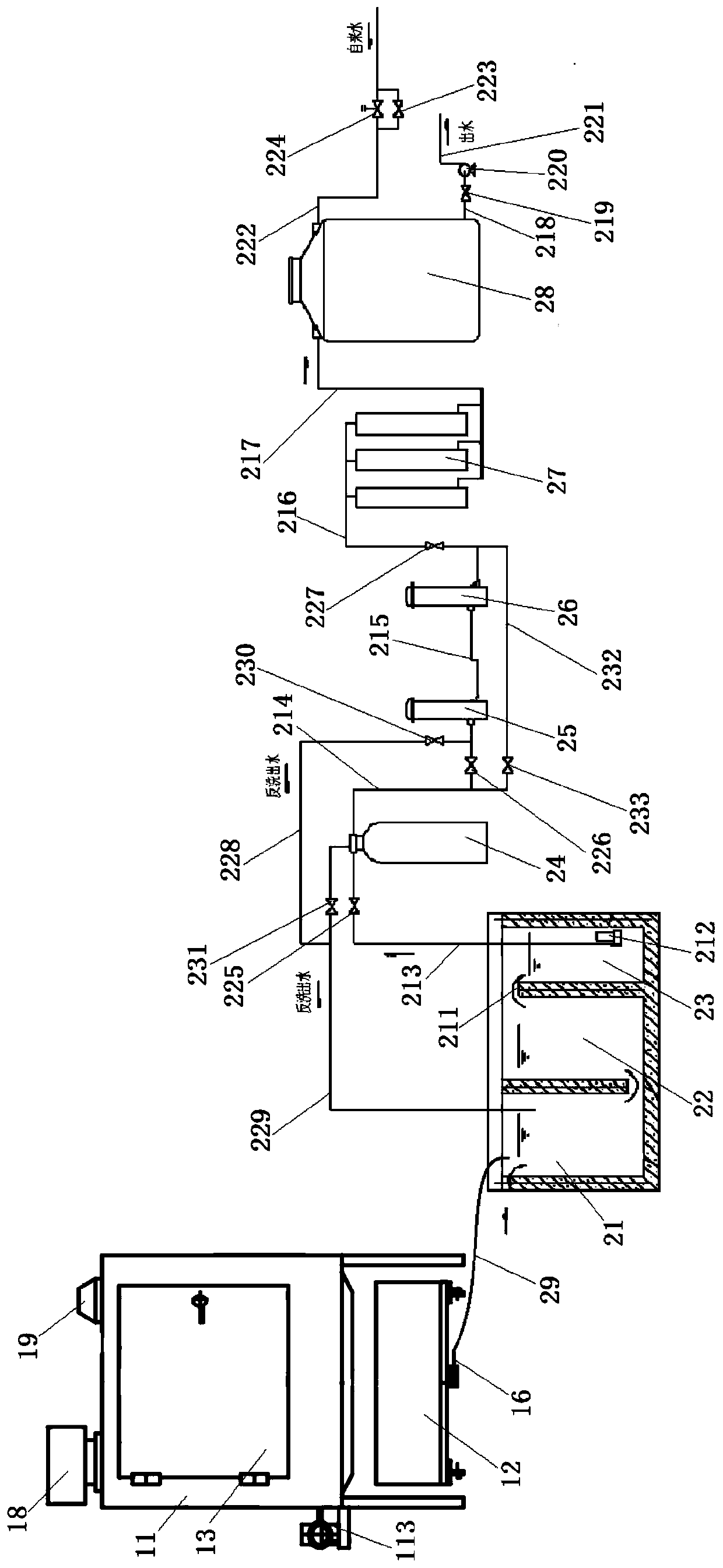

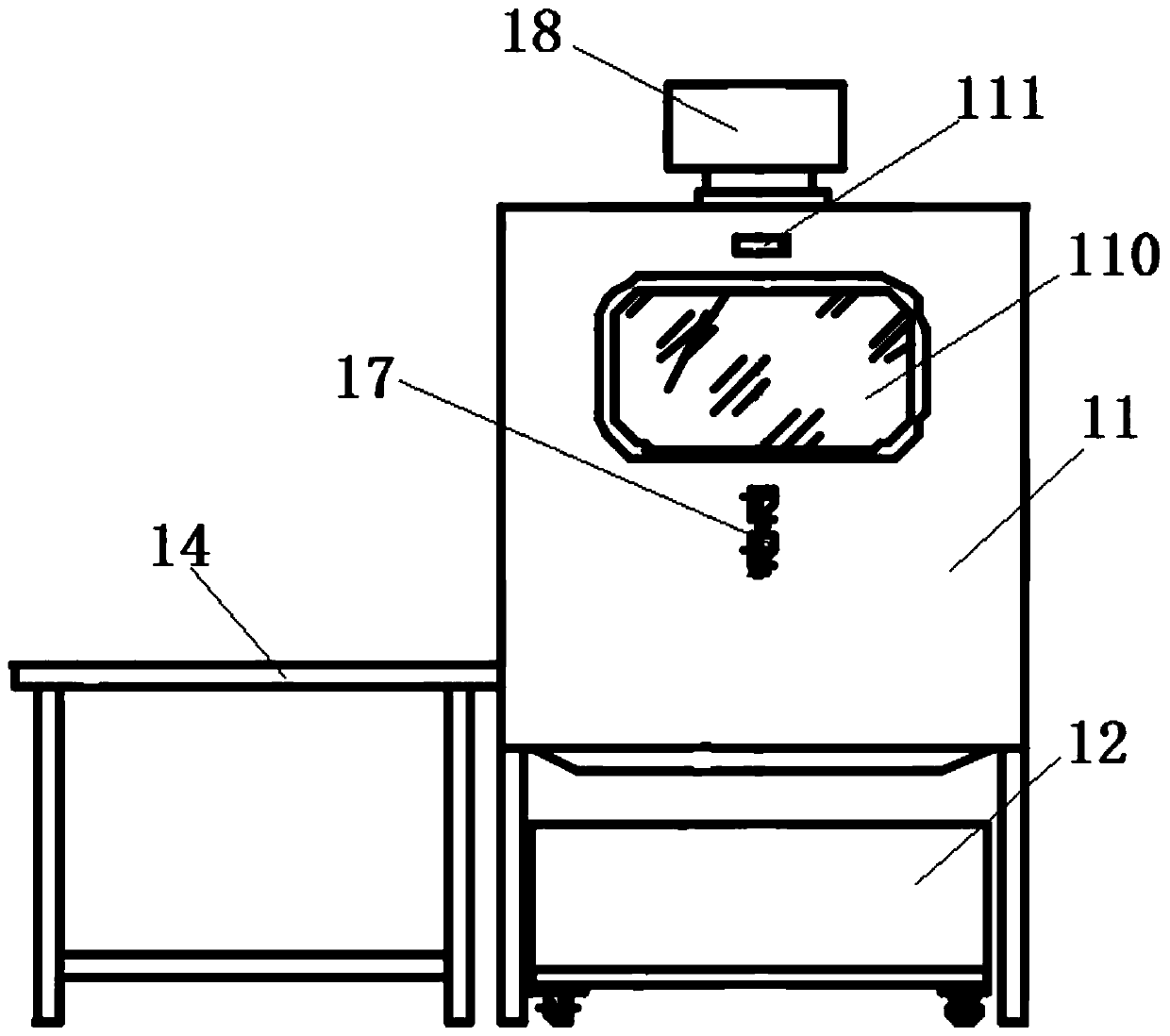

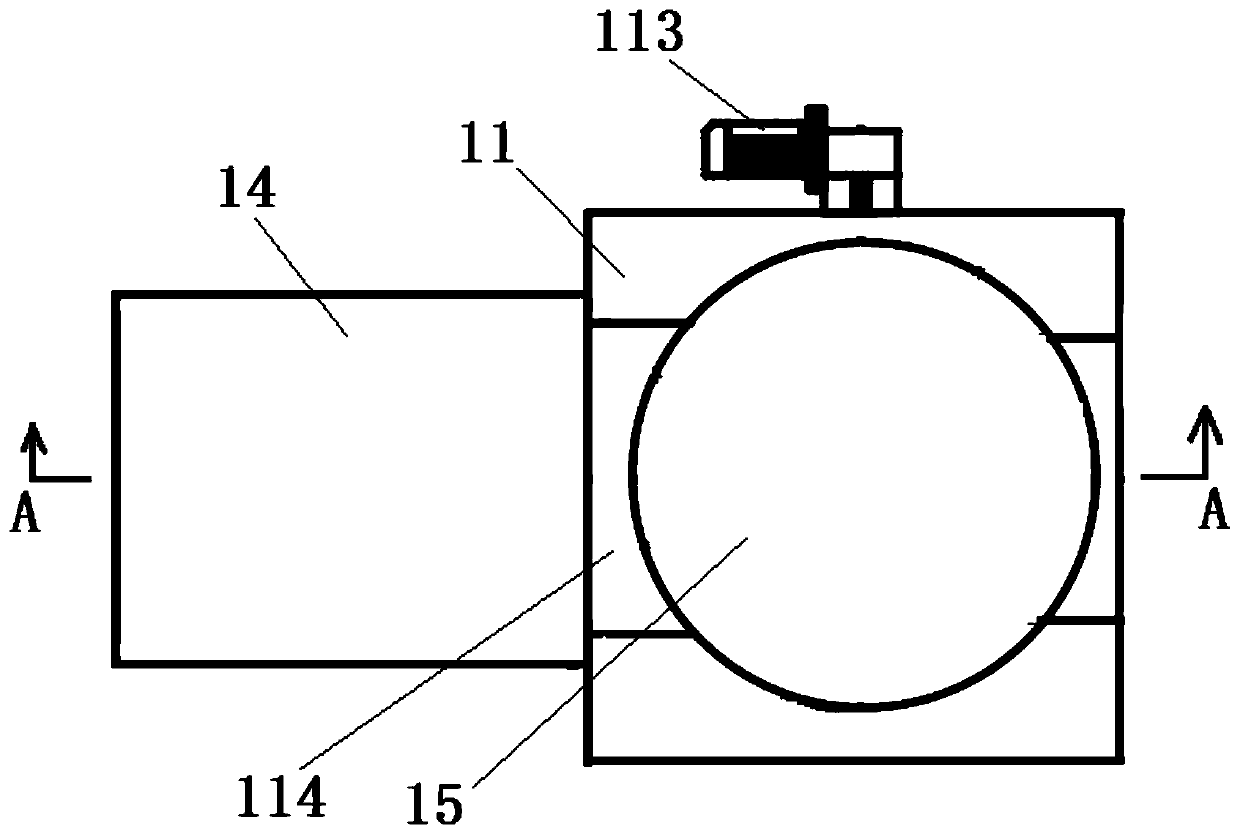

[0036] Such as Figure 1-4 As shown, a sand cleaning treatment system for castings includes a sand cleaning device and a water circulation system;

[0037] The sand cleaning device comprises a sand cleaning chamber 11, a sand collection box 12 arranged directly below the sand cleaning chamber 11, and a workpiece vehicle platform 14 fixed on one side of the airtight door 13 of the sand cleaning chamber 11. The sand cleaning chamber The inner bottom of 11 is provided with a rotating platform 15, the rotating platform 15 is fixed with the sand cleaning chamber 11 through a bracket, and a fixing screw hole is opened on the rotating platform 15, and the fixing screw hole is used to fix the workpiece through a fixing piece Car, the bottom of the sand cleaning chamber 11 is provided with drainage holes, and the waste water produced by sand cleaning flows into the sand collection box 12 from the drainage outlet. The top of the sand collection box 12 is open, and the bottom of the sand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com