A kind of composite air filter material that can be washed repeatedly and preparation method thereof

A technology of air filter material and melt-blown filter material, which is applied in the field of industrial textiles, can solve the problems of increasing pressure drop and not being suitable for mass production, and achieves the effects of mild preparation conditions, improved filtration stability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

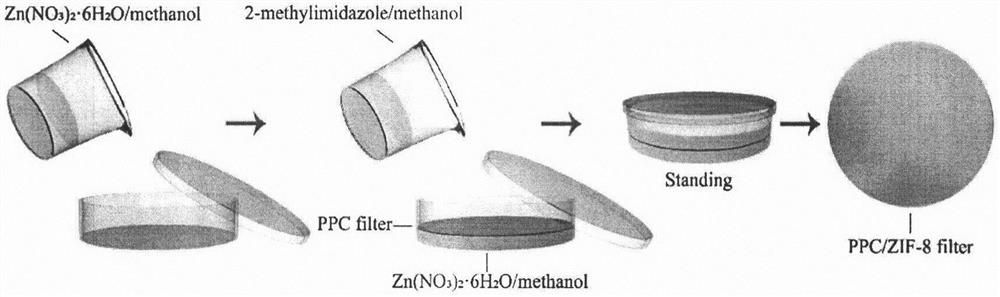

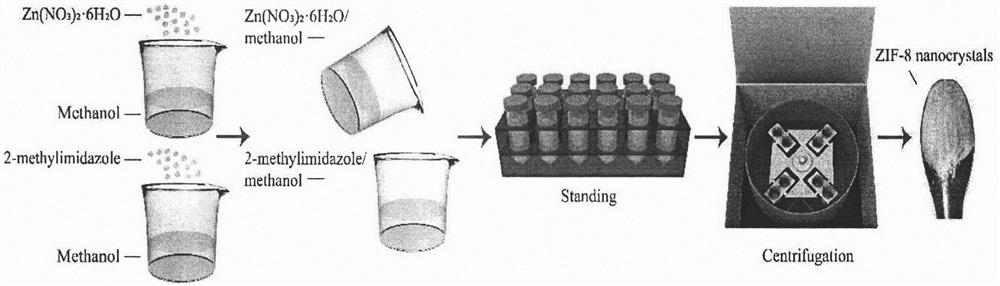

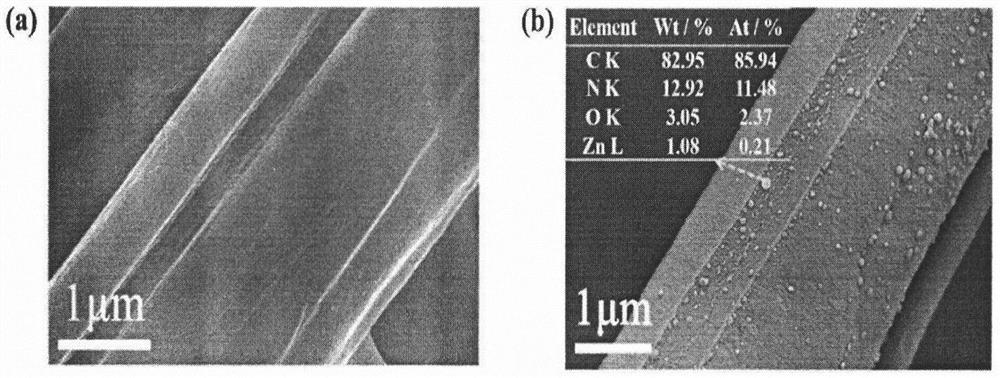

[0027] The technical problem to be solved by the present invention is to invent a preparation method of a composite air filter material that can be repeatedly washed with water.

[0028] Step 1. Dry polypropylene and polycarbonate polymer with a mass ratio of 97:3 in a blast drying oven, respectively. The melt index and melting point of polypropylene are 35g / 10min and 169°C, respectively. The melt index of polycarbonate is and the melting points are 14.4g / 10min and 250℃ respectively; after drying, the polycarbonate and polypropylene are uniformly mixed and granulated by a single screw granulator to prepare a two-component polypropylene / polycarbonate masterbatch;

[0029] Step 2. Dry the polypropylene / polycarbonate masterbatch obtained in step 1 with a blast drying oven; after the single-screw melt-blown equipment reaches the preset temperature and stabilizes, pour the polypropylene / polycarbonate masterbatch into the melt. The feeding barrel of the spray equipment, the molten p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com