Copper foil-graphene current collector and preparation method thereof

A current collector, graphene composite technology, applied in the direction of graphite, sustainable manufacturing/processing, electrode carrier/current collector, etc., can solve the problems of reduced energy density and power density, shortened cycle life, unfavorable mass production, etc. Achieve the effects of inhibiting expansion and detachment, reducing interface polarization, and reducing thermal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. A method for continuously preparing copper foil-graphene composite negative electrode current collectors

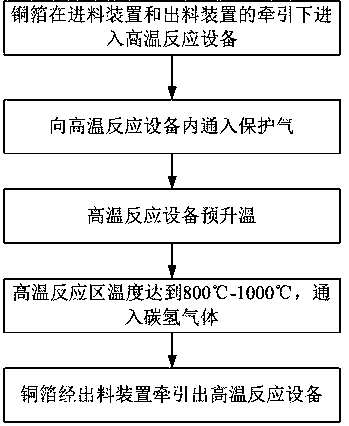

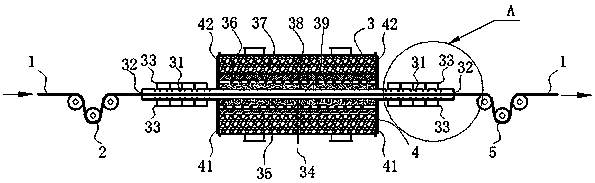

[0034] refer to figure 1 , a method for preparing a copper foil-graphene composite negative electrode current collector, the preparation method is prepared by a continuous chemical vapor deposition (CVD) method, and specifically includes the following steps:

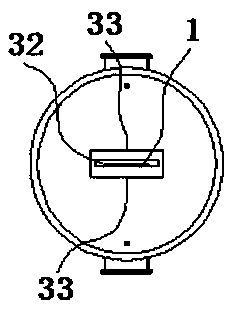

[0035] 1) The copper foil enters the high temperature reaction equipment 3 smoothly through the air seal 32 under the joint traction drive of the feeding device and the discharging device;

[0036] 2) Pass the protective gas argon into the high temperature reaction equipment 3, and the gas supply volume is 1m 3 / h-10m 3 / h;

[0037] 3) Before the reaction, slowly pre-heat the high-temperature reaction equipment 3, and at the same time fill the gas seal device 31 with protective gas to ensure that the high-temperature area inside the equipment is in an oxygen-free state, and the temperature rise rate doe...

Embodiment 2

[0047] One, a kind of preparation method of copper foil-graphene composite negative electrode current collector

[0048] A method for preparing a copper foil-graphene composite negative electrode current collector is based on the equipment described in Example 1. The preparation method is prepared by a continuous chemical vapor deposition (CVD) method, and specifically includes the following steps:

[0049] 1) The copper foil enters the high temperature reaction equipment 3 smoothly through the air seal 32 under the joint traction drive of the feeding device and the discharging device;

[0050] 2) Pass the protective gas argon into the protective gas sealing device 31, and the gas supply volume is 1m 3 / h-10m 3 / h;

[0051] 3) Before the reaction, slowly pre-heat the high-temperature reaction equipment 3, and at the same time fill the gas seal device 31 with protective gas to ensure that the high-temperature area inside the equipment is in an oxygen-free state, and the tempe...

Embodiment 3

[0055] One, a kind of preparation method of copper foil-graphene composite negative electrode current collector

[0056] A method for preparing a copper foil-graphene composite negative electrode current collector is based on the equipment described in Example 1. The preparation method is prepared by a continuous chemical vapor deposition (CVD) method, and specifically includes the following steps:

[0057] 1) The copper foil enters the high temperature reaction equipment 3 smoothly through the air seal 32 under the joint traction drive of the feeding device and the discharging device;

[0058] 2) Pass the protective gas argon into the high temperature reaction equipment 3, and the gas supply volume is 1m 3 / h-10m 3 / h;

[0059] 3) Before the reaction, slowly pre-heat the high-temperature reaction equipment 3, and at the same time fill the gas seal device 31 with protective gas to ensure that the high-temperature area inside the equipment is in an oxygen-free state, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com