Filling method of dot matrix cell structure part

A filling method and technology for structural parts, applied in the direction of instrument, geometric CAD, design optimization/simulation, etc., can solve the problems of non-uniform distribution of internal stress, insufficient stress, material waste, etc., achieve reasonable lattice arrangement, reduce difficulty and time, the effect of speeding up the simulation analysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Filling design of lattice cell structure of automobile bracket parts.

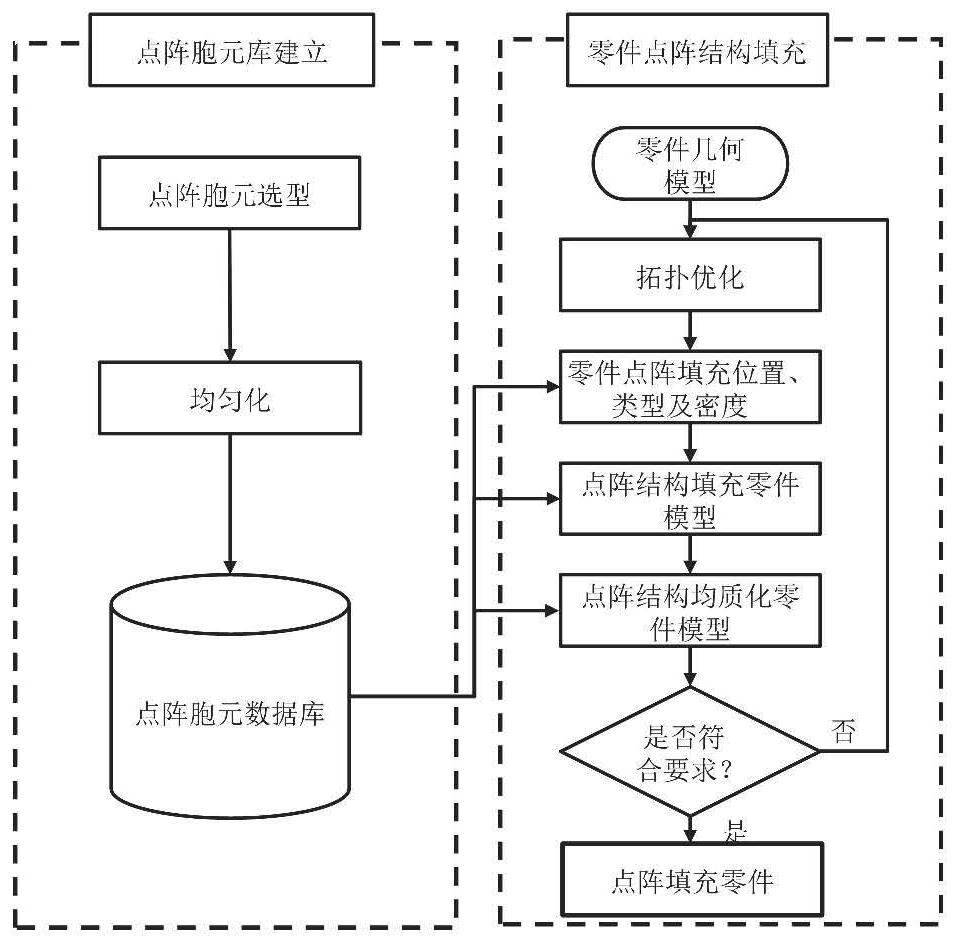

[0050] like figure 1 As shown, this embodiment proposes and discloses a method for filling parts with a lattice cell structure, including:

[0051] Step 1: Select the lattice cell structure based on part design requirements and manufacturability constraints, and use homogenization to build a lattice cell mechanical property library consisting of relative density, Young's modulus, shear modulus, and Poisson's ratio.

[0052] like Figure 2-1 to Figure 2-4 As shown, in the first embodiment, four lattice cell structures of body-centered cubic structure, edge structure, body-centered cubic structure and face-centered cubic structure are selected.

[0053] The mechanical properties of the lattice cell structure were obtained by the homogenization method. The selected material was ABS, the elastic modulus was 1830Mpa, and the Poisson's ratio was 0.35. The size of the single cell was selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com