A kind of preparation method of PE hose

A technology of hoses and extruders, which is applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of affecting irrigation effects, branch pipe joints falling off, and the reduction of pressure bearing capacity of PE hoses, so as to achieve less labor intensity and improve Pressure bearing capacity, effect of reducing meter weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

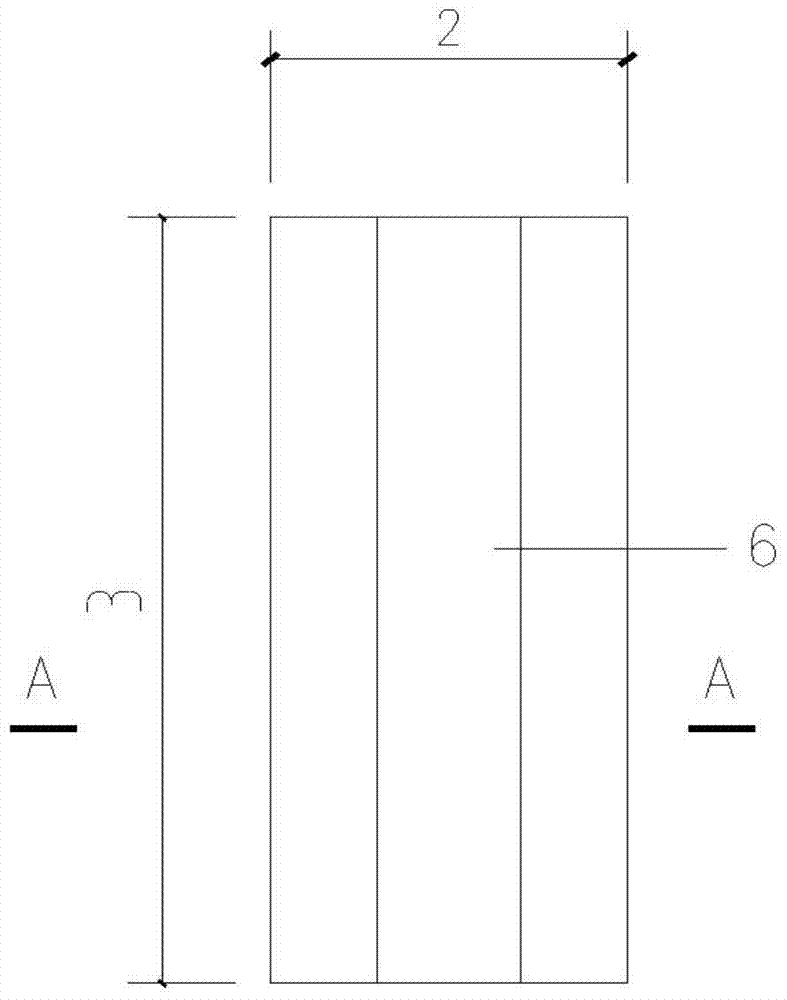

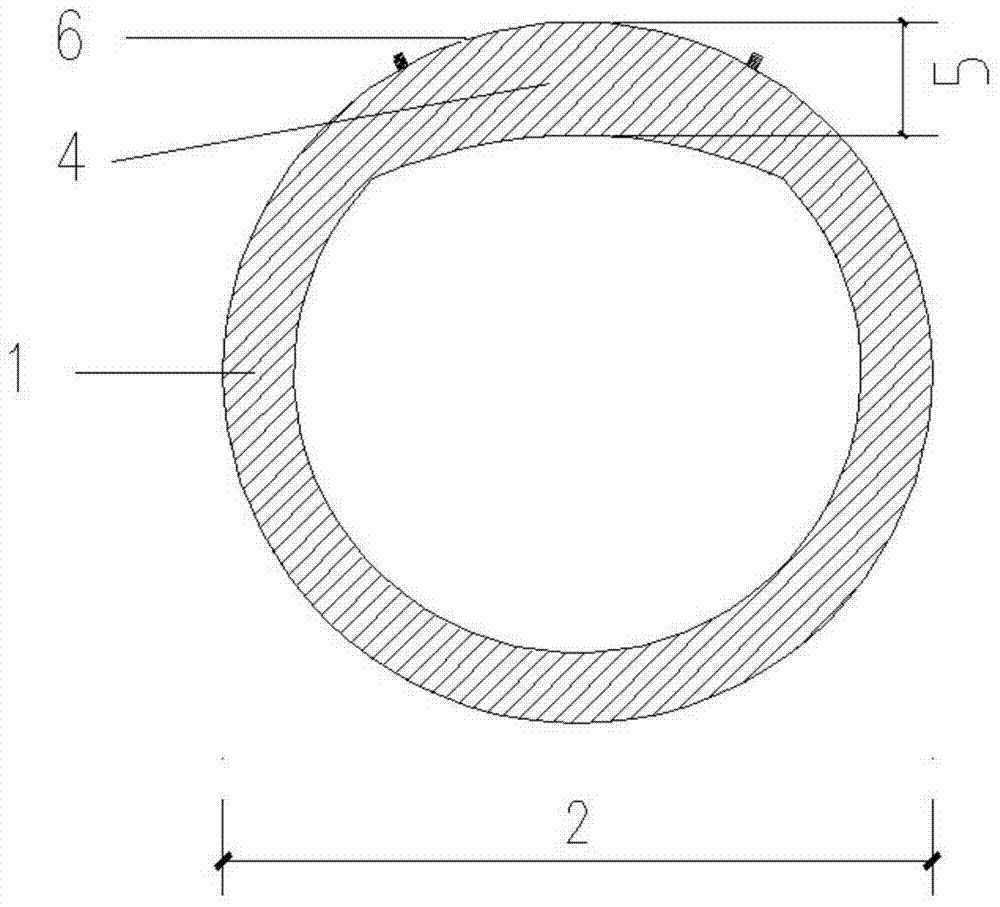

[0036] Example 1: A PE hose made of linear low-density polyethylene, low-density polyethylene, high-density polyethylene, black masterbatch and antioxidant. It is characterized in that there are local thickening areas on the pipe wall, which are locally increased. The thickness of the thick zone is 1.0-2.5mm, and the arc length of the inner wall of the local thickening zone is 25-60mm. The thickness of the local thickening zone and the inner wall arc length of the local thickening zone increase with the increase of pipe diameter. The specific relationship is as follows The table shows:

[0037]

[0038] There are two marking areas on the outer wall of the local thickening area, the color of the marking area is blue, and the distance between the two lines is 40mm.

Embodiment 2

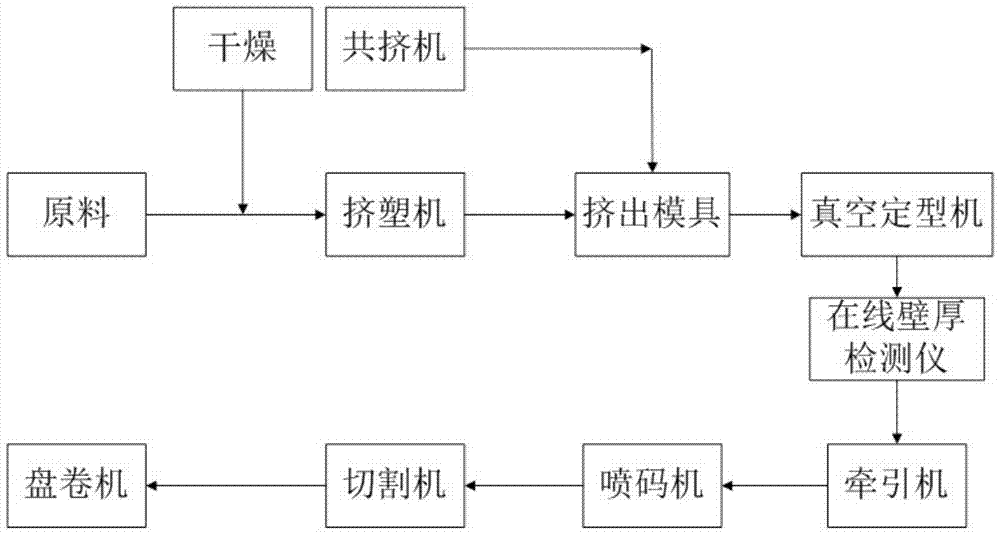

[0039] Example 2: A method for preparing a PE hose, including an extruder, a co-extruder, a vacuum setting machine, and a tractor, characterized in that an extrusion die is installed on the extruder mold body, and the extrusion die consists of It consists of a core mold, a die, and a co-extrusion sleeve. The die is installed outside the core mold, and the co-extrusion sleeve is installed on the die and connected to the co-extrusion machine. The feature is that the outer wall of the core mold is designed with an arc groove and the groove depth is 0.5mm. , The groove arc length is 25mm, the groove mouth is installed upwards, the die is designed with a co-extrusion material inlet, and the co-extrusion sleeve is designed with a co-extrusion runner. The specific production is carried out as follows:

[0040] Step 1: Drying: Put the main materials of linear low-density polyethylene, low-density polyethylene, and high-density polyethylene into the dryer, blow in hot air at 75°C, and dry ...

Embodiment 3

[0047] Example 3: A method for preparing a PE hose, including an extruder, a co-extruder, a vacuum setting machine, and a tractor, characterized in that an extrusion die is installed on the extruder mold body, and the extrusion die consists of It consists of a core mold, a die, and a co-extrusion sleeve. The die is installed outside the core mold, and the co-extrusion sleeve is installed on the die and connected to the co-extrusion machine. The feature is that the outer wall of the core mold is designed with an arc groove, and the groove depth is 0.3mm , The groove arc length is 40mm, the groove mouth is installed upwards, a co-extrusion inlet is designed on the die, and a co-extrusion runner is designed on the inside of the co-extrusion sleeve. The specific production is carried out as follows:

[0048] Step 1: Drying: Put the main materials of linear low-density polyethylene, low-density polyethylene and high-density polyethylene into the dryer, blow in hot air at 75°C, and dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com