Polyethylene (PE) flexible pipe

A hose and pipe wall technology, which is applied to the locally thickened PE hose and its manufacturing field, can solve the problems of affecting the irrigation effect, the branch pipe joint falling off, and the pressure bearing capacity of the PE hose decrease, so as to achieve less labor intensity, Effect of improving pressure bearing capacity, reducing rice weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

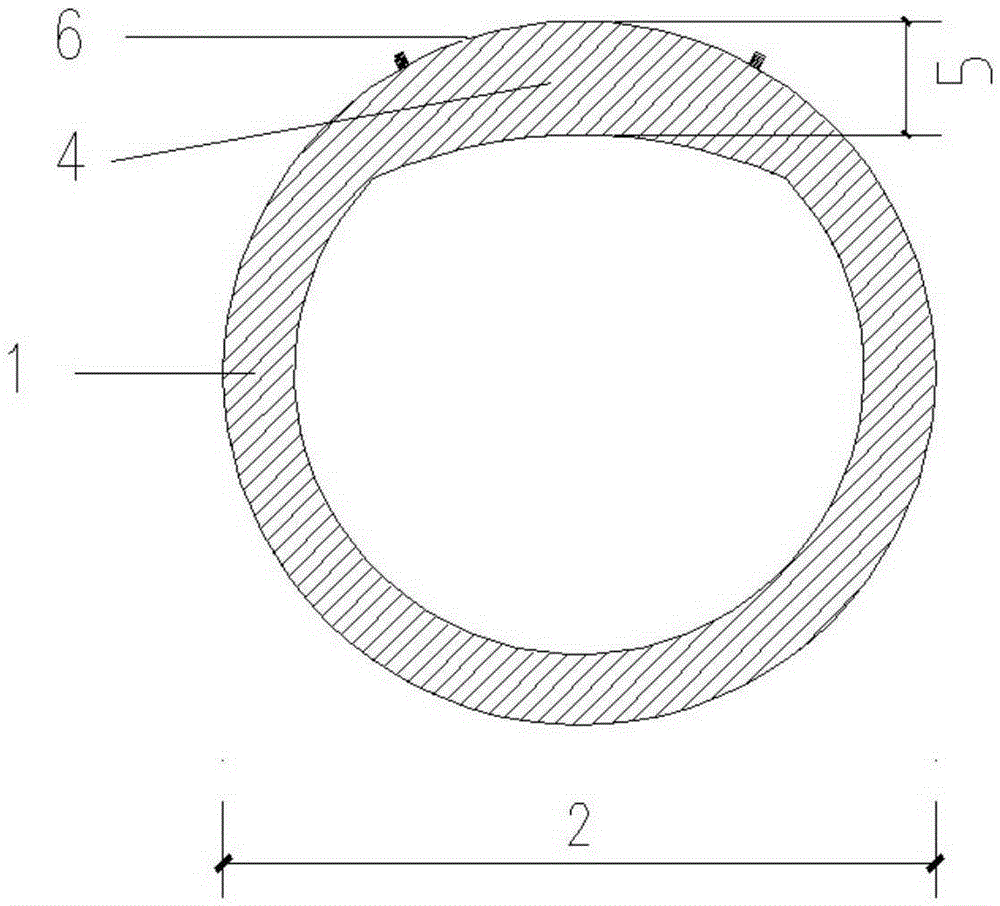

[0036] Embodiment 1: A kind of PE hose is prepared by using linear low-density polyethylene, low-density polyethylene, high-density polyethylene, black masterbatch and antioxidant, and is characterized in that there is a local thickening zone on the pipe wall, and the local thickening The thickness of the thick zone is 1.0-2.5mm, and the inner wall arc length of the local thickening zone is 25-60mm. The thickness of the local thickening zone and the inner wall arc length of the local thickening zone increase with the increase of the pipe diameter. The specific relationship is as follows As shown in the table:

[0037]

[0038] There are two marking areas on the outer wall of the local thickening area, the color of the marking area is blue, and the distance between the two lines is 40mm.

Embodiment 2

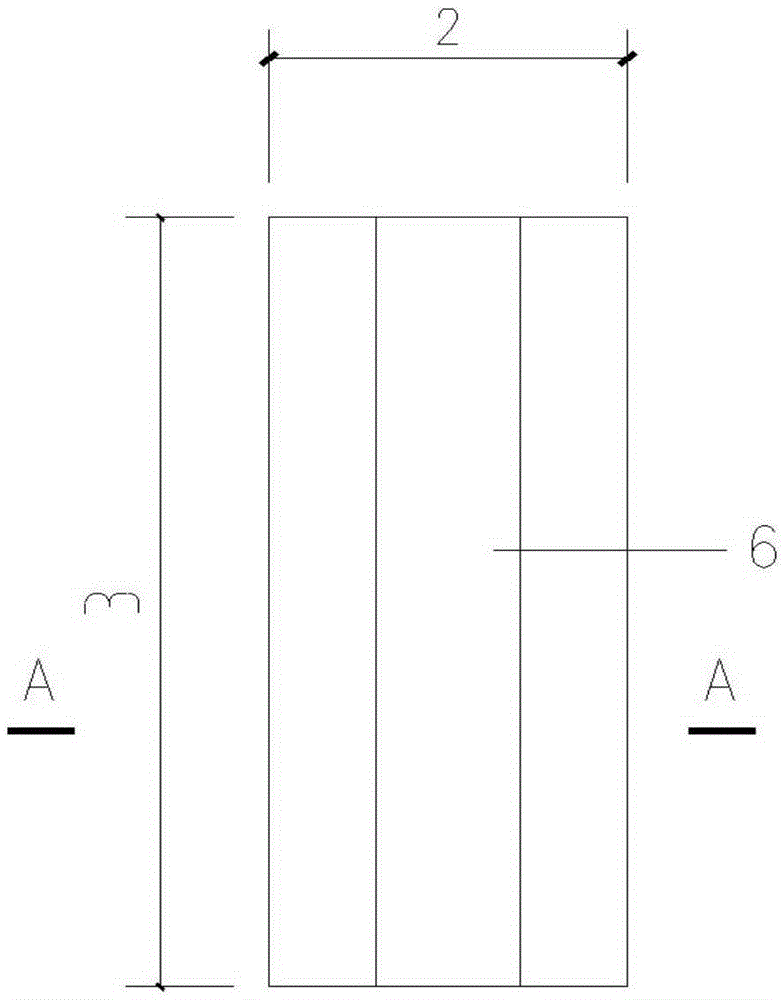

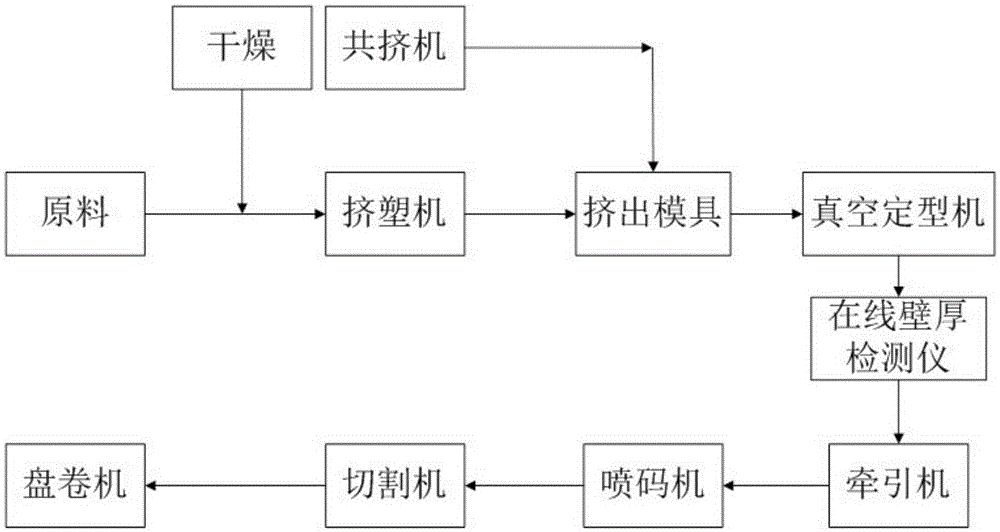

[0039] Embodiment 2: a kind of preparation method of PE hose, comprising extruder, co-extrusion machine, vacuum setting machine, haul-off machine, it is characterized in that extruding die is installed on extruder die body; Described extruding die consists of Composed of mandrel, die, and co-extrusion sleeve, the die is installed outside the mandrel, and the co-extrusion sleeve is installed on the die to connect with the co-extrusion machine. It is characterized in that an arc-shaped groove is designed on the outer wall of the mandrel, and the depth of the groove is 0.5mm. , the arc length of the groove is 25mm, and the groove mouth is installed upward; the die is designed with a co-extrusion material inlet; the inner side of the co-extrusion sleeve is designed with a co-extrusion flow channel; the specific production is carried out as follows:

[0040] The first step is to dry the material, put the main material linear low-density polyethylene, low-density polyethylene, and hi...

Embodiment 3

[0047] Embodiment 3: a kind of preparation method of PE hose, comprising extruder, co-extrusion machine, vacuum setting machine, haul-off machine, it is characterized in that extrusion mold is installed on extruder mold body; Said extrusion mold consists of Composed of mandrel, die and co-extrusion sleeve, the die is installed outside the mandrel, and the co-extrusion sleeve is installed on the die to connect with the co-extrusion machine. It is characterized in that an arc-shaped groove is designed on the outer wall of the mandrel, and the depth of the groove is 0.3mm. , the arc length of the groove is 40mm, and the groove opening is installed upwards; the die is designed with a co-extrusion material inlet; the inner side of the co-extrusion sleeve is designed with a co-extrusion flow channel; the specific production is carried out as follows:

[0048] The first step is to dry the material, put the main material linear low-density polyethylene, low-density polyethylene and hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com