Water-based silicon-modified polyester coil steel coating and preparation method thereof

A water-based silicone and polyester technology, applied in the direction of polyester coatings, coatings, etc., can solve the problems of low water resistance, poor weather resistance, poor heat resistance, etc., and achieve the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

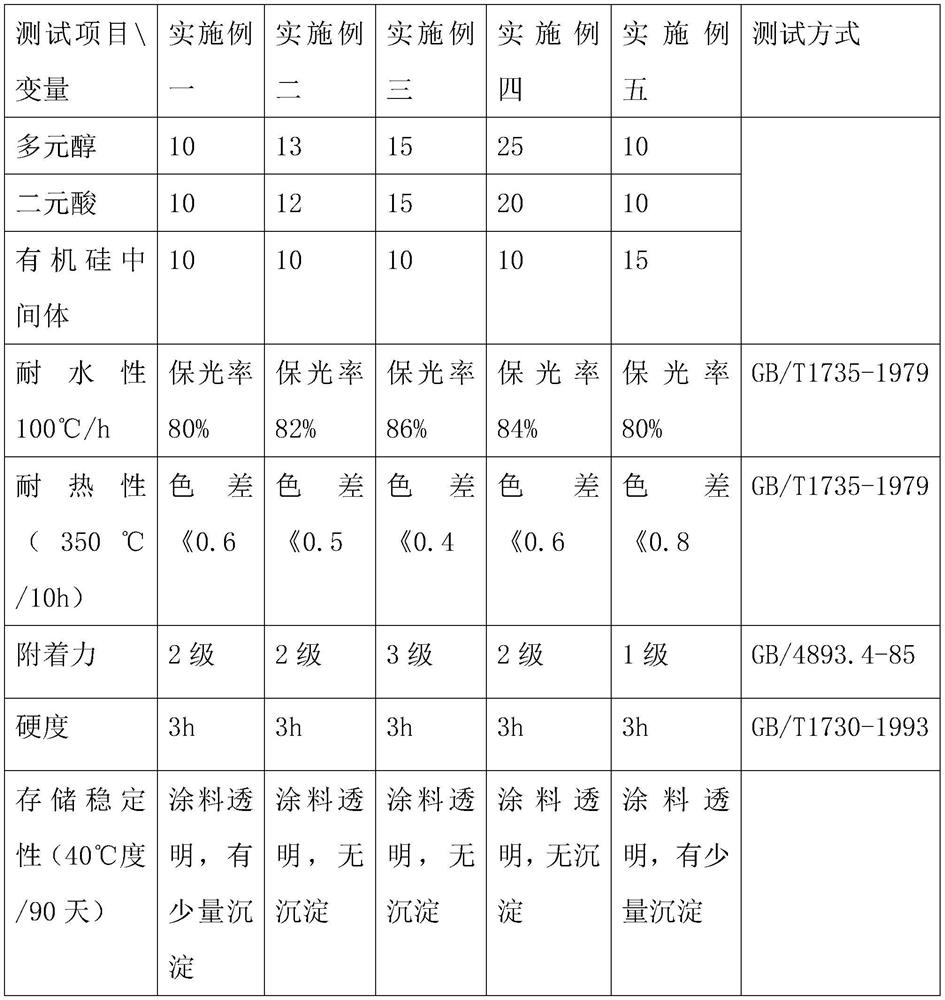

Examples

Embodiment 1

[0025] A water-based silicon-modified polyester coil coating, comprising the following raw materials in parts by weight: 10 parts of polyols, 10 parts of dibasic acids, 0.02 parts of esterification catalysts, 0.02 parts of modified catalysts, 10 parts of organic silicon intermediates, and 4 parts of acid anhydrides. parts, 2 parts of organic amines, 5 parts of pigments, 5 parts of fillers, 0.3 parts of wetting agent, 0.2 parts of dispersant and 20 parts of deionized water.

[0026] As the technical solution of the present invention, a preparation method of water-based silicon-modified polyester is also proposed, comprising the following specific steps:

[0027] S1, 10 parts of polyols and 10 parts of dibasic acids are added to the reactor simultaneously, and the temperature is raised to 150-220° C. When the temperature reaches 150-220° C., the thermal insulation esterification is performed for 0.5 hours at this time to obtain mixed solution a. ;

[0028] S2, reduce the temper...

Embodiment 2

[0034] A water-based silicon-modified polyester coil coating, comprising the following raw materials in parts by weight: 13 parts of polyols, 12 parts of dibasic acids, 0.02 parts of esterification catalysts, 0.02 parts of modified catalysts, 10 parts of organic silicon intermediates, and 4 parts of acid anhydrides. parts, 2 parts of organic amines, 5 parts of pigments, 5 parts of fillers, 0.3 parts of wetting agent, 0.2 parts of dispersant and 20 parts of deionized water.

[0035] As the technical solution of the present invention, a preparation method of water-based silicon-modified polyester is also proposed, comprising the following specific steps:

[0036] S1, 13 parts of polyols and 12 parts of dibasic acids are added to the reaction kettle simultaneously, and the temperature is raised to 150-220°C, when the temperature reaches 150-220°C, insulation esterification is performed for 0.5 hours at this time to obtain mixed solution a ;

[0037] S2, reduce the temperature of...

Embodiment 3

[0043] A water-based silicon-modified polyester coil coating, comprising the following raw materials by weight: 15 parts of polyols, 15 parts of dibasic acids, 0.02 parts of esterification catalysts, 0.02 parts of modified catalysts, 10 parts of organic silicon intermediates, and 4 parts of acid anhydrides. parts, 2 parts of organic amines, 5 parts of pigments, 5 parts of fillers, 0.3 parts of wetting agent, 0.2 parts of dispersant and 20 parts of deionized water.

[0044] As the technical solution of the present invention, a preparation method of water-based silicon-modified polyester is also proposed, comprising the following specific steps:

[0045] S1, 15 parts of polyols and 15 parts of dibasic acids are added to the reactor simultaneously, and the temperature is raised to 150-220° C. When the temperature reaches 150-220° C., the thermal insulation esterification is performed for 0.5 hours at this time to obtain mixed solution a. ;

[0046] S2, reduce the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com