Composite resin material for 3D printing as well as preparation method and application thereof

A composite resin and 3D printing technology, applied in the direction of additive processing, etc., can solve the problem of low mixing degree of resin materials, achieve high heat resistance temperature, simple preparation method, and good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

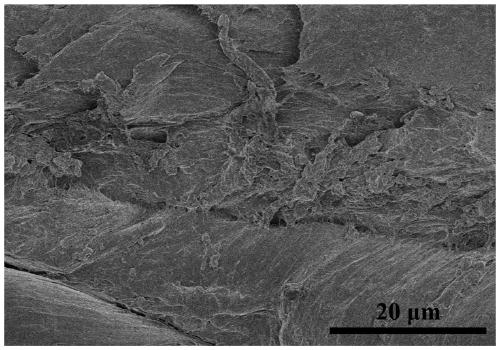

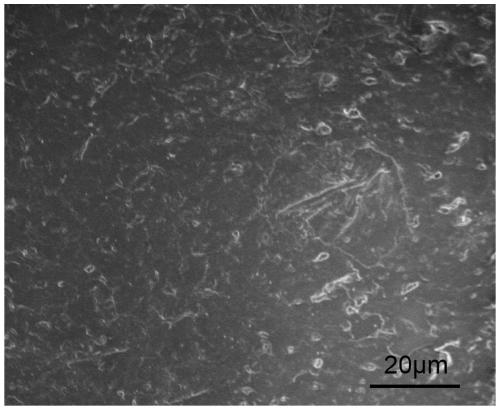

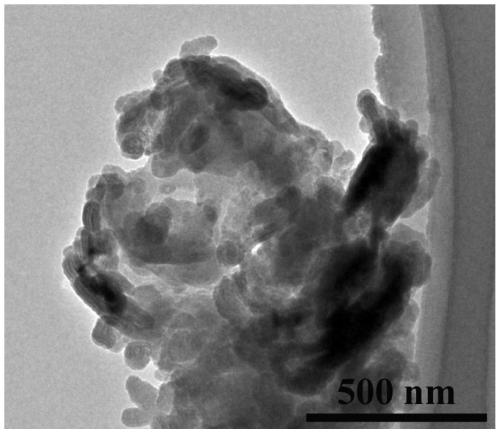

Image

Examples

preparation example Construction

[0050] In a preferred embodiment of the present invention, the preparation method of the above-mentioned composite resin material includes the following steps: mixing polylactic acid, polyurethane elastomer and lysozyme / carbon nanotube solution added as required in an organic solvent, removing the solvent, The composite resin material can be obtained.

[0051] In a preferred embodiment of the present invention, the preparation method of above-mentioned composite resin material comprises the following steps:

[0052] 1) Dissolution and compounding: Add 25g of polylactic acid into 150g of N,N dimethylformamide (DMF) solvent, stir for 40min-60min in a water bath at 80-90°C and a speed of 400 rpm, and the polylactic acid is completely dissolved , continue to add 1.25 ~ 5g polyurethane elastomer and stir for 10min-20min, at this time the two materials have been completely mixed to obtain a composite solution;

[0053] 2) Distillation under reduced pressure: Distill the compound so...

Embodiment 1

[0068] 1) Dissolving and compounding: Add 25g of polylactic acid into 150g of N,N dimethylformamide solvent, stir for 40min in a water bath at 85°C and a speed of 400 rpm, add 5g of polyurethane elastomer and continue stirring for 10min to obtain compound liquid;

[0069] 2) Distillation under reduced pressure: Distill the compound liquid in step 1) at a vacuum degree of 20kPa and a temperature of 60°C for 4 hours to remove the solvent. At this time, the compound liquid has become viscous to obtain a polylactic acid / polyurethane elastomer compound Crude resin product;

[0070] 3) Drying: move the crude product of step 2) into a mold, put the mold into a vacuum drying oven, and dry for 24 hours at a temperature of 50° C. and a vacuum of 80 kPa to obtain the composite resin material of this embodiment.

Embodiment 2

[0072] 1) Dissolving and compounding: Add 25g of polylactic acid into 150g of N,N dimethylformamide solvent, stir for 50min in a water bath at 85°C and a speed of 400 rpm, add 2.5g of polyurethane elastomer and continue stirring for 11min, get compound liquid;

[0073] 2) Distillation under reduced pressure: Distill the compound liquid in step 1) at a vacuum degree of 30kPa and a temperature of 60°C for 4 hours to remove the solvent. At this time, the compound liquid has become viscous to obtain a polylactic acid / polyurethane elastomer compound Crude resin product;

[0074] 3) Drying: move the crude product of step 2) into a mold, put the mold into a vacuum drying oven, and dry for 24 hours at a temperature of 50° C. and a vacuum of 70 kPa to obtain the composite resin material of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com