A kind of method of sol-gel method modified benzoxazine resin/epoxy resin copolymer

A technology of sol-gel method and epoxy resin, which is applied in the field of preparation of organic polymer compounds, can solve the problems of low thermal stability of the blend system, toughness is not as good as that of pure epoxy resin, and does not maximize its advantages, and achieves thermal stability. Excellent stability, reduced thermal stability, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

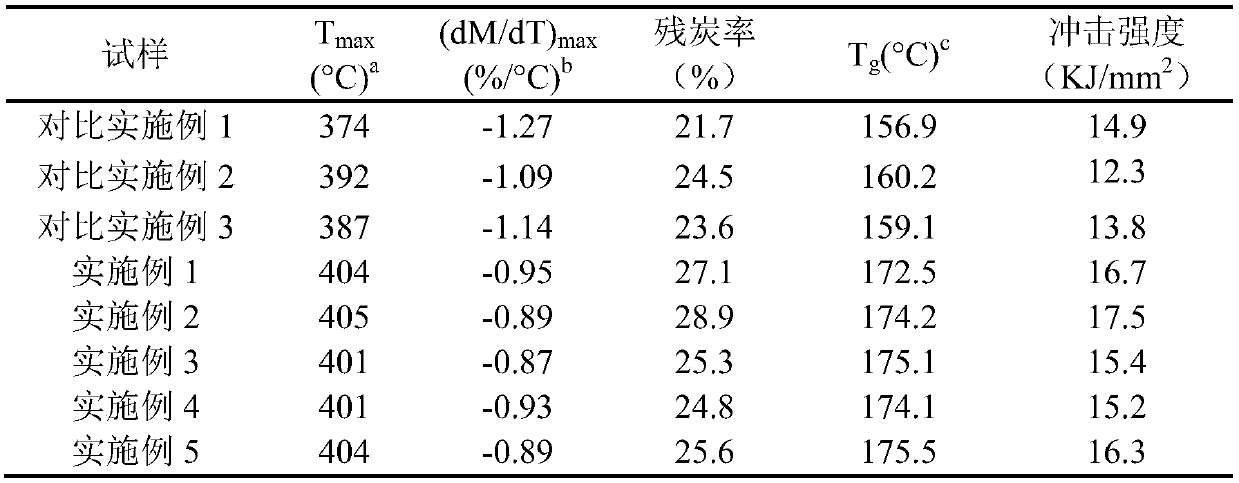

Examples

Embodiment 1

[0039] Step 1. with bisphenol F epoxy resin (epoxy value 0.51), 3-isocyanopropyltriethoxysilane is mixed with molar ratio 15: 1, and adding quality is 0.2% of the above-mentioned reactant quality sum Dibutyltin laurate (catalyst) was reacted at 50° C. for more than 5 hours to obtain a siloxane-modified glycidyl ether epoxy resin (a).

[0040] Step 2. Silicone-modified glycidyl ether epoxy resin (a), bisphenol A benzoxazine resin (b), and tetraethyl orthosilicate (c) are mixed according to the molar ratio of 1.5:0.8:0.2 , dissolved in acetone, heated to 50°C, the amount of the acetone added is twice the sum of the mass of the siloxane-modified glycidyl ether epoxy resin, the benzoxazine resin and the silica precursor.

[0041] Step 3. adding an aqueous acetic acid solution with a pH of 3-4 to the solution obtained in step 2, the amount of the aqueous acetic acid solution being 5% of the total mass of the reactants in step 2.

[0042] Step 4. After reacting for 3 hours, remove ...

Embodiment 2

[0046] Step 1. with bisphenol F epoxy resin (epoxy value 0.51), 3-isocyanopropyltriethoxysilane is mixed with molar ratio 10:1, and adding quality is 0.2% of the above-mentioned reactant quality sum Dibutyltin laurate was reacted at 50° C. for more than 5 hours to obtain a siloxane-modified glycidyl ether epoxy resin (a).

[0047] Step 2. Silicone-modified glycidyl ether epoxy resin (a), bisphenol A benzoxazine resin (b), and tetraethyl orthosilicate (c) are mixed according to the molar ratio of 2:1:0.3 , dissolved in acetone, the solution is heated to 50 ° C, the addition of the acetone is siloxane-modified glycidyl ether epoxy resin, benzoxazine resin and silica precursor mass sum of 4 times.

[0048] Step 3. adding an aqueous acetic acid solution with a pH of 3-4 to the solution obtained in step 2, the amount of the aqueous acetic acid solution being 4% of the total mass of the reactants in step 2.

[0049] Step 4. After reacting for 3 hours, water and acetone were remove...

Embodiment 3

[0052] Step 1. with bisphenol F epoxy resin (epoxy value 0.51), 3-isocyanopropyltriethoxysilane is mixed with molar ratio 10:1, and adding quality is 0.2% of the above-mentioned reactant quality sum Dibutyltin laurate was reacted at 50° C. for more than 5 hours to obtain a siloxane-modified glycidyl ether epoxy resin (a).

[0053] Step 2. Silicone-modified glycidyl ether epoxy resin (a), bisphenol A benzoxazine resin (b), and tetraethyl orthosilicate (c) are mixed according to the molar ratio of 1:1:0.1 , dissolved in acetone, and the solution was heated to 50°C. The amount of acetone added is twice the sum of the mass of the siloxane-modified glycidyl ether epoxy resin, the benzoxazine resin and the silica precursor.

[0054] Step 3. adding an aqueous acetic acid solution with a pH of 3-4 to the solution obtained in step 2, the amount of the aqueous acetic acid solution being 4% of the total mass of the reactants in step 2.

[0055] Step 4. After reacting for 3 hours, water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com