Temperature-controllable magnetic stirrer and working method thereof

A magnetic stirrer and temperature controller technology, applied in chemical instruments and methods, mixer accessories, dissolution, etc., can solve the problems of affecting the experimental effect, easy to move, affecting the magnetic induction effect, etc., to improve the dissolution efficiency and structural design Reasonable and solve the effect that is not easy to take out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

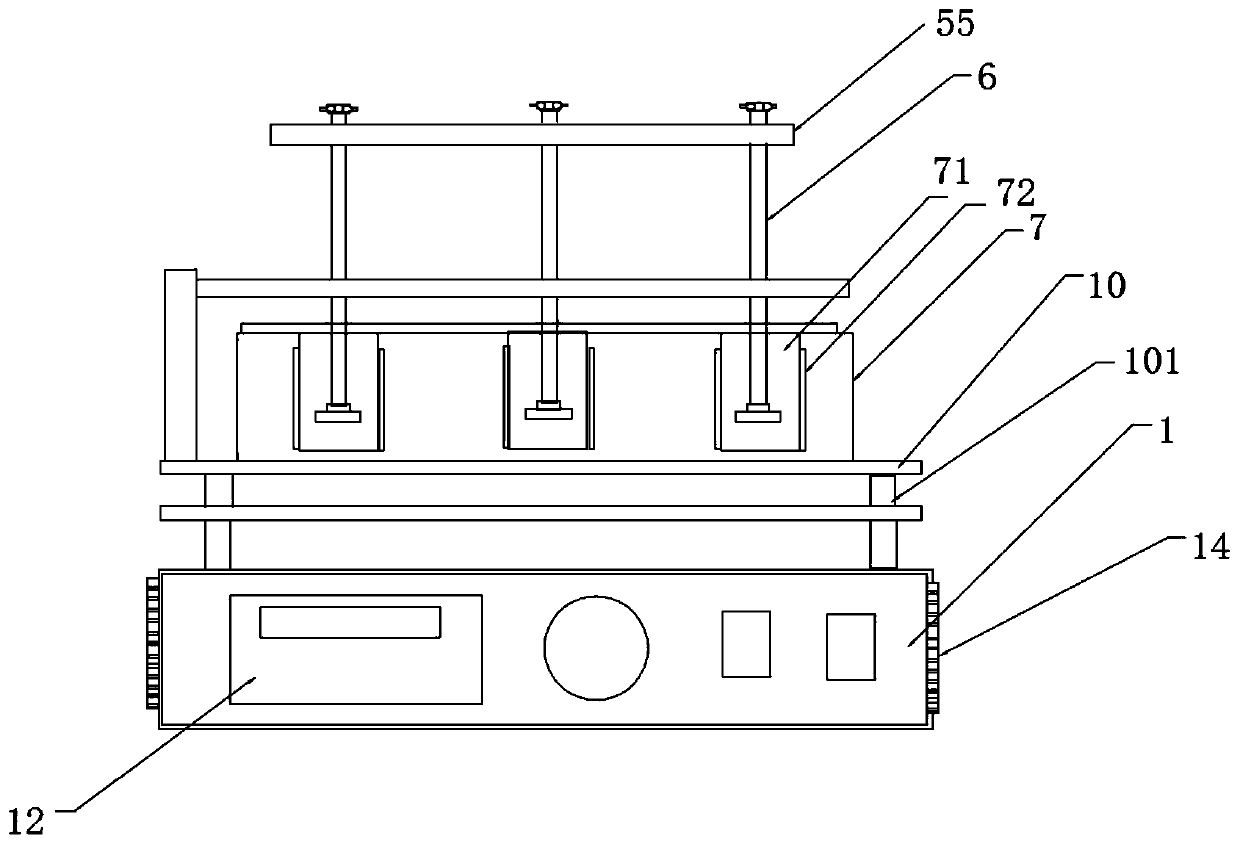

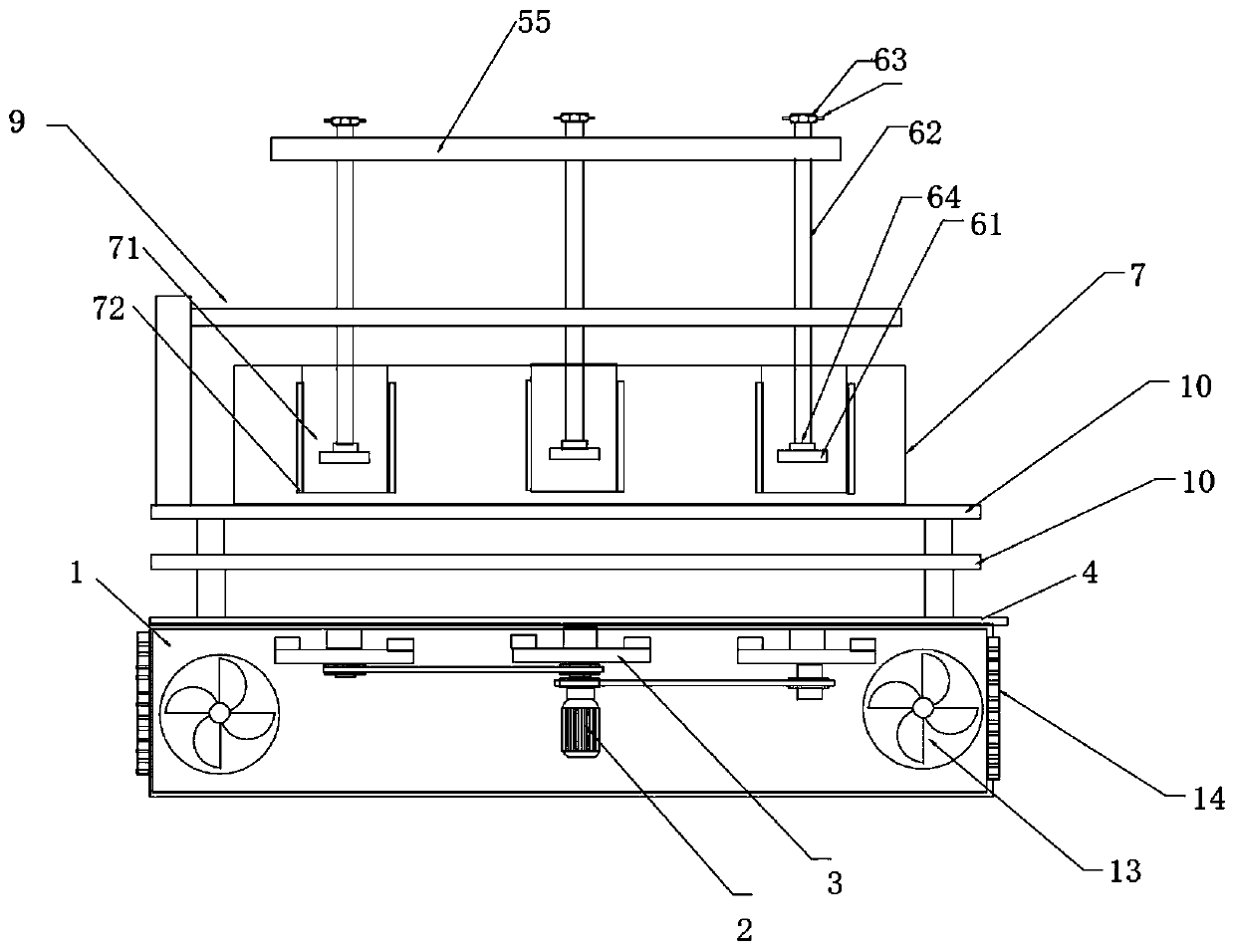

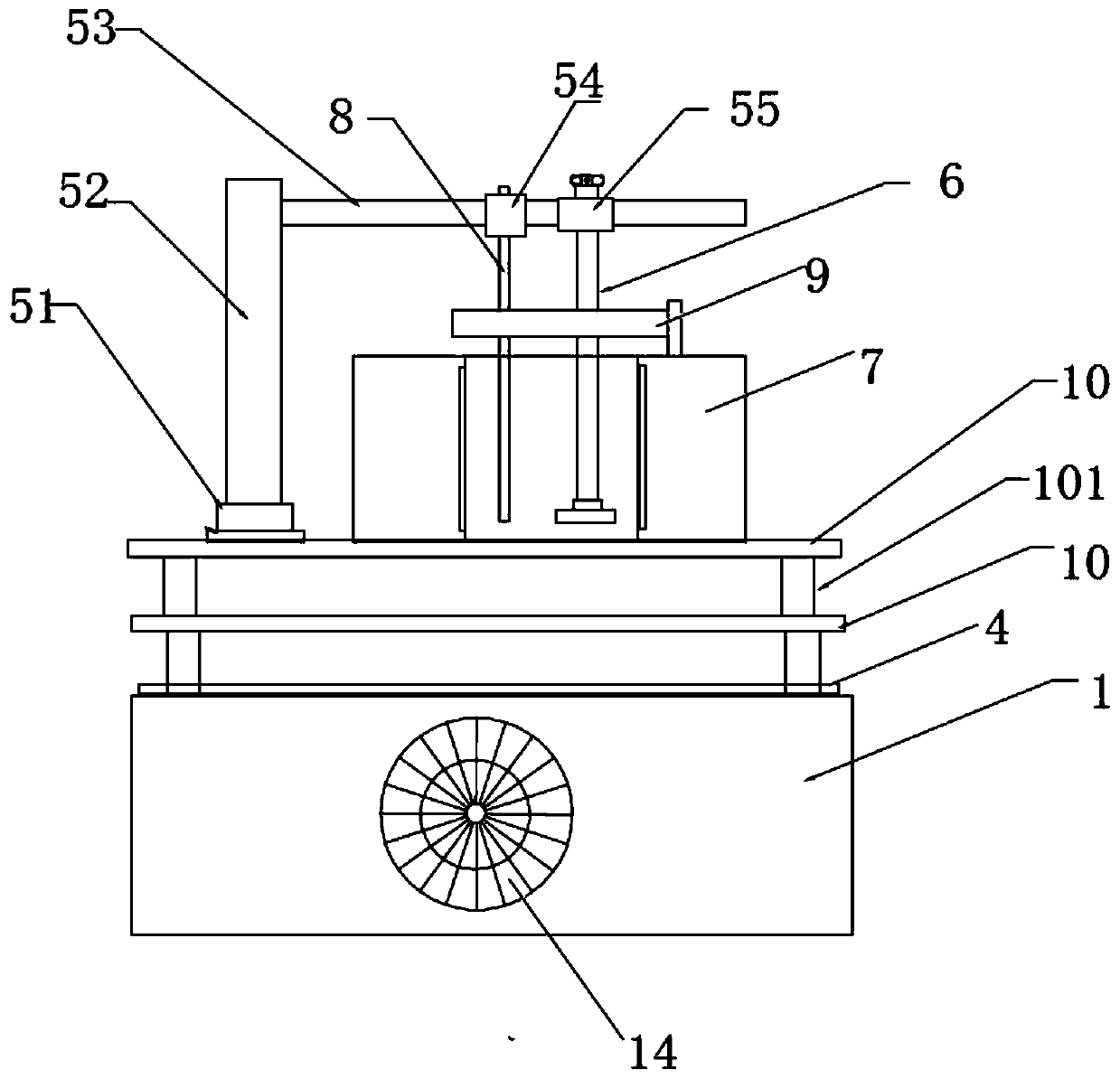

[0019] like Figure 1-4 The temperature-controllable magnetic stirrer shown includes a base 1, a motor 2, a magnet support 3, a stage 4, a support assembly 5, a stirring body 6, a stainless steel pot body 7 and a temperature sensor 8, and the base 1 is equipped with Motor 2 and magnet support 3 are arranged, and described magnet support 3 comprises magnet support one 31, magnet support two 32 and magnet support three 33, and above-mentioned 3 magnet supports are respectively installed in base 1 by drive shaft, and magnet support two 32 The output shaft of drive shaft and motor 2 is connected by coupling, and the output shaft of described motor 2 is provided with 2 drive wheels, and the drive shafts of magnet support one 31 and magnet support three 33 are all provided with driven wheels, driving wheels and the driven wheel are driven by belts; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com