Preforming device for copper flat wire precision welding

A technology of precision welding and copper flat wire, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve problems such as mold difficulties, joints are easy to break, and affect the cleanliness of the working environment, so as to eliminate post-processing links and improve the overall structure Simplicity and the effect of reducing quality risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

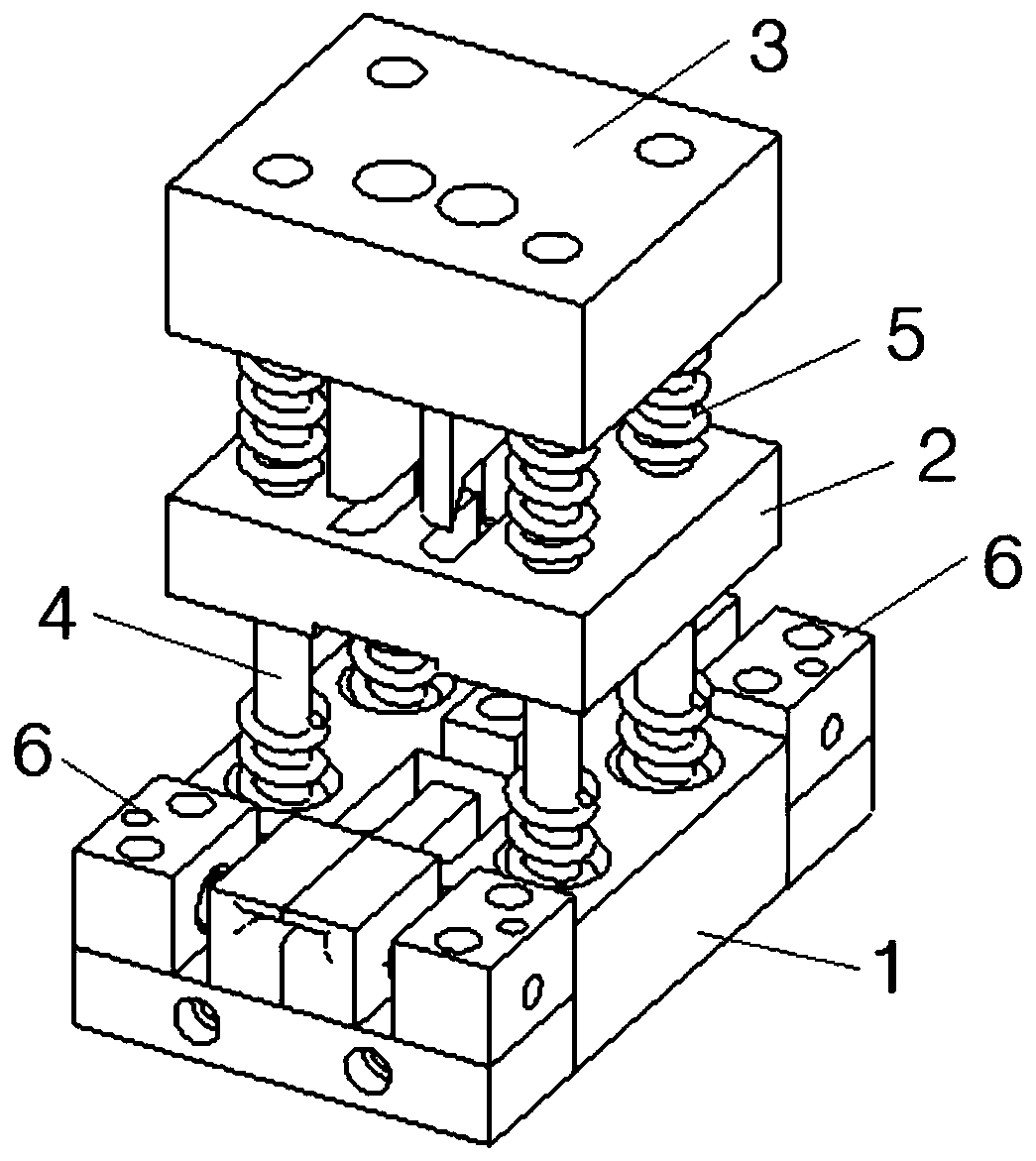

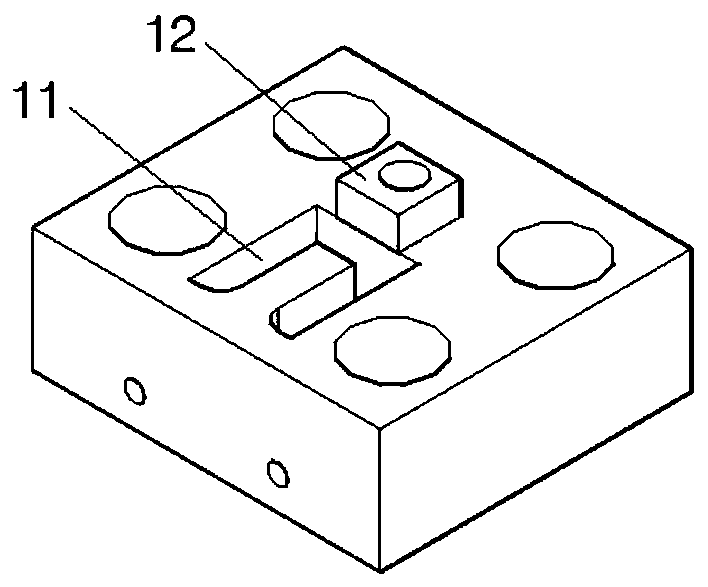

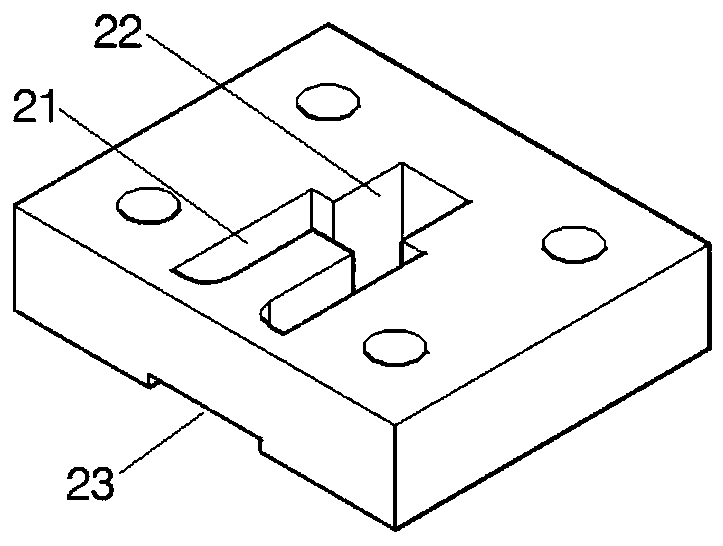

[0020] Such as Figure 1-5 Shown: copper flat wire precision welding preforming device, including base 1, stamping plate 3, pressing plate 2, guide post 4, spring 5 and centering device 6. The base 1 is the basis of the device, and a cavity 11 is opened in the middle of the base 1, and the cavity 11 is U-shaped; the stamping plate 3 is installed on the base 1 by using the guide post 4, and the bottom surface of the stamping plate 3 is provided with a punch 31; 2 Installed in the middle of the guide column 4, the position corresponding to the punch 31 on the pressure plate 2 is provided with a guide hole 21, the shape of the guide hole 21 is consistent with the cross-sectional shape of the punch 31, the pressure plate 2 and the base 1 together press the copper Flatten the flat wire, or press and fix the flat copper wire so that the punch 31 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com