Design method of secondary cooling water and preparation method of continuous casting slab in high carbon steel continuous casting process

A technology of continuous casting process and design method, applied in the field of iron and steel smelting, can solve the problem of not considering the relationship between the billet pulling speed and the amount of secondary cooling water, and achieve small shrinkage, low thermal shrinkage coefficient, and no center segregation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 12~14 and comparative example 1~3

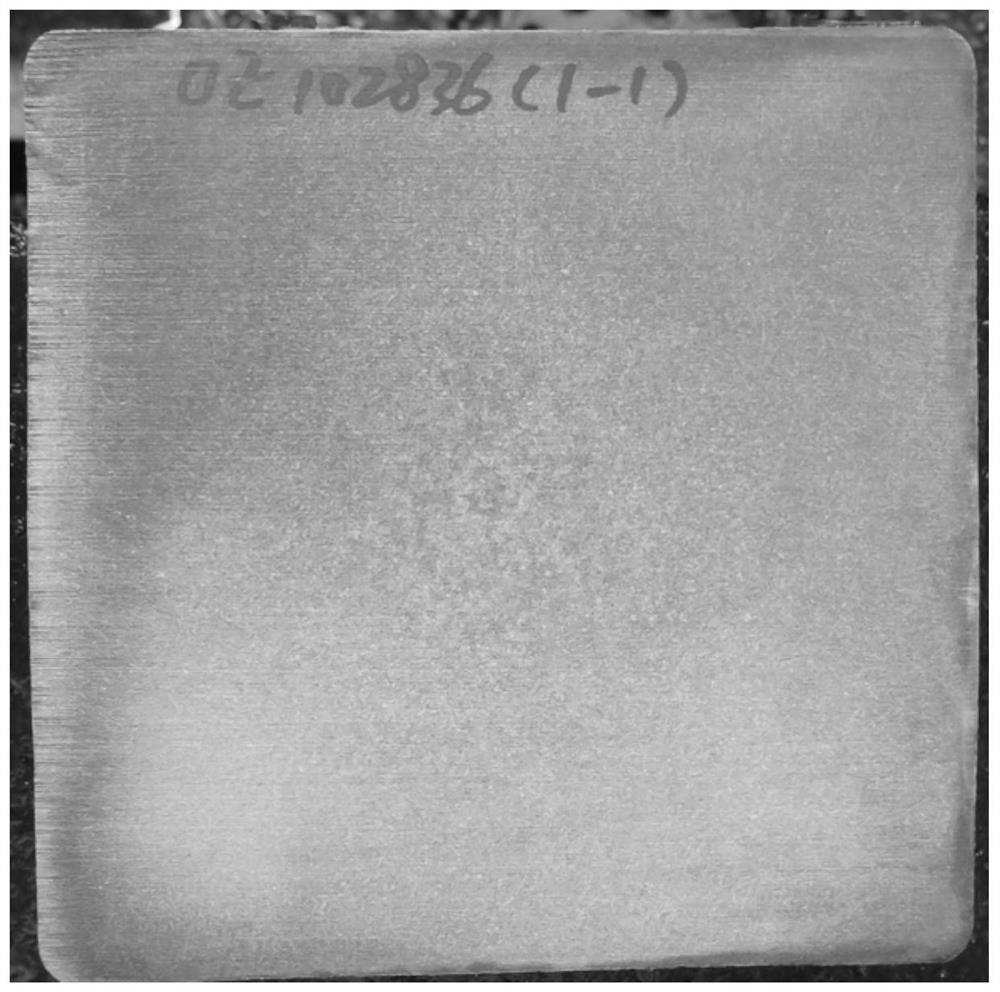

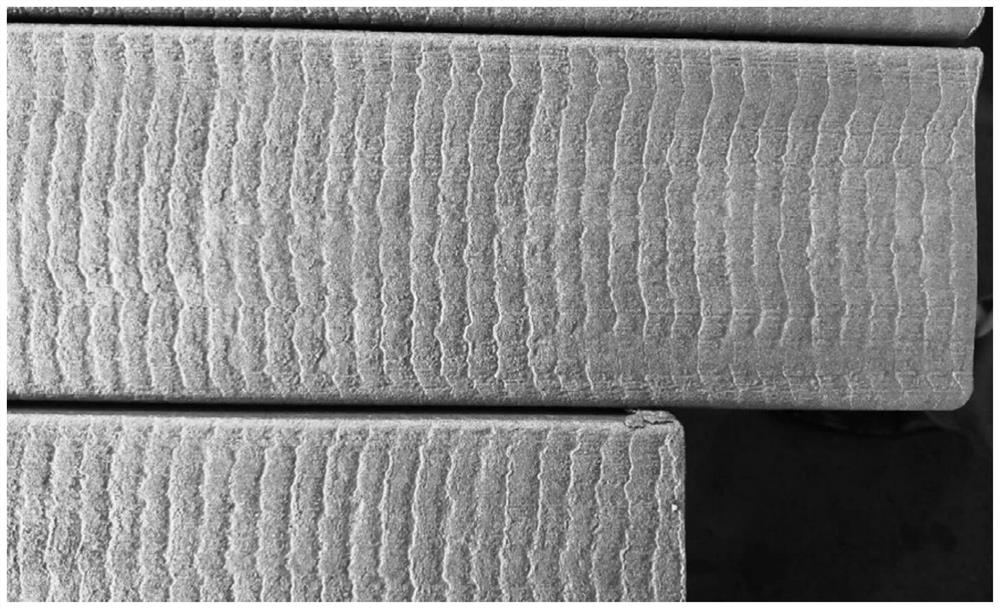

[0109] Embodiments 12-14 and Comparative Examples 1-3 all provide a method for preparing high-carbon steel continuous casting slabs, and the manufacturing steps and high-carbon steel components are the same. The difference lies in the process parameters of mold flux and crystallizer. Examples 12-14 and Comparative Examples 1-3 The design of the secondary cooling water is the same as that of Example 11, the casting speed is 2.1m / min, and the specific water volume of the secondary cooling water is 0.49-0.57L / kg. Specific different process parameters are shown in Table 3 to Table 5:

[0110] Table 3 Chemical Composition of Mold Flux (wt%)

[0111]

[0112] Table 4 Physical indicators of mold flux

[0113] Mold flux Melting point / ℃ Melting speed / S Bulk density g / ml Viscosity pa.s Alkalinity Example 12 1043 41 0.71 0.286 0.65 Example 13 1053 40 0.70 0.295 0.63 Example 14 1064 39 0.72 0.267 0.66 Comparative example 1 1112 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com