Leveling and acid pickling production line capable of controlling transverse crease defects

A technology of horizontal crease and washing production line, applied in the direction of contour control, metal rolling, manufacturing tools, etc., can solve the problems of wasting energy, increasing the amount of cutting, and high production costs, reducing production costs, increasing production efficiency, and saving energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

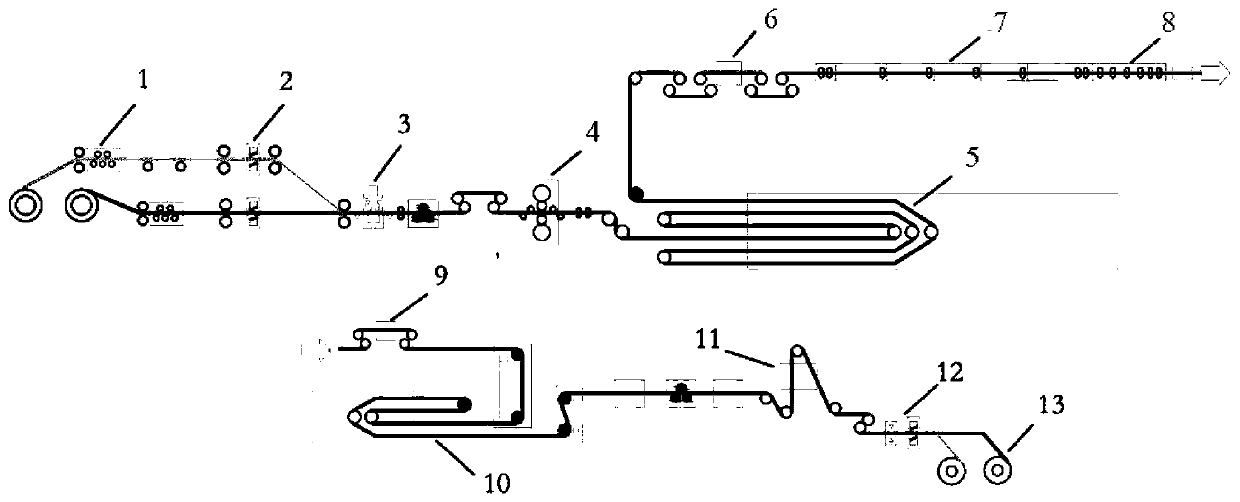

[0017] Such as figure 1 As shown, the present invention is a leveling and pickling production line for controlling transverse crease defects, including an uncoiler 1, an inlet shear 2, a welding machine 3, a skin passer 4, an inlet looper 5, and a scale breaker 6 connected in sequence , pickling section 7, rinsing section 8, tension straightening machine 9, export looper 10, export shear 12 and coiler 13.

[0018] It is also possible to add an oiler 11 between the outlet looper and the outlet shear according to the situation, and then carry out an oiling or non-oiling process according to the final product situation.

[0019] In the optimization scheme, a walking beam feeding device is added before the uncoiler 1.

[0020] The technical route adopted is: feeding→uncoiling→shearing→welding→leveling→entry looper→scale breaking machine→pickling→...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com