Fatigue-resistant enamel steel for water heater inner container and preparation process thereof

A water heater liner and preparation technology, which is applied in the steel rolling process and metallurgy fields, can solve the problems of poor processing performance, decreased elongation, and increased production difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

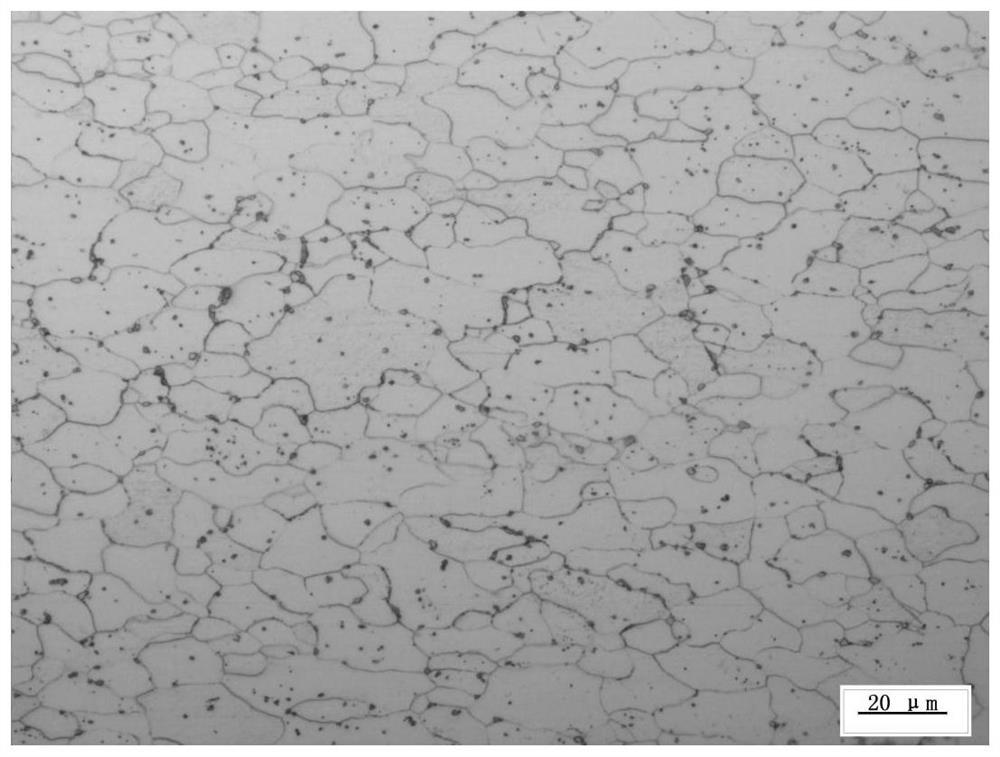

Image

Examples

Embodiment 1-3

[0032] Embodiment 1-3: The manufacturing method of this low-cost enamelled steel is carried out according to the following steps.

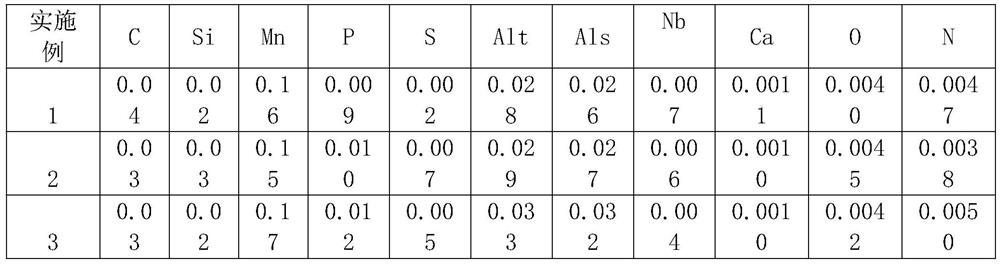

[0033] (1) The chemical composition of the steel coil in each embodiment is shown in Table 1, wherein the balance is Fe and unavoidable impurity elements.

[0034] Table 1: the chemical composition (Wt%) of each embodiment product

[0035]

[0036] (2) According to the composition ratio in Table 1, go through processes such as molten iron desulfurization, converter smelting, and LF refining; The temperature is 570°C, and the thickness of the hot coil is 4.5mm; the hot-rolled steel coil produced is pickled to remove the scale and then cold-rolled, the reduction rate is 60%, and the thickness of the cold-rolled coil is 1.8mm; the cold-rolled steel coil is hooded Annealing, the annealing temperature is 690°C, the annealing time is 8 hours, and the slow cooling time is 2 hours; finally, after the smoothing process, the elongation rate is set to 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com