Automatic collection and arrangement hydraulic flattening machine for environment-friendly waste

A technology for automatic collection and waste, applied in the direction of presses, manufacturing tools, etc., can solve the problems of poor standardization, garbage blocks can not be neatly stacked and filled, and achieve the effect of simple and practical structure and low production and processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

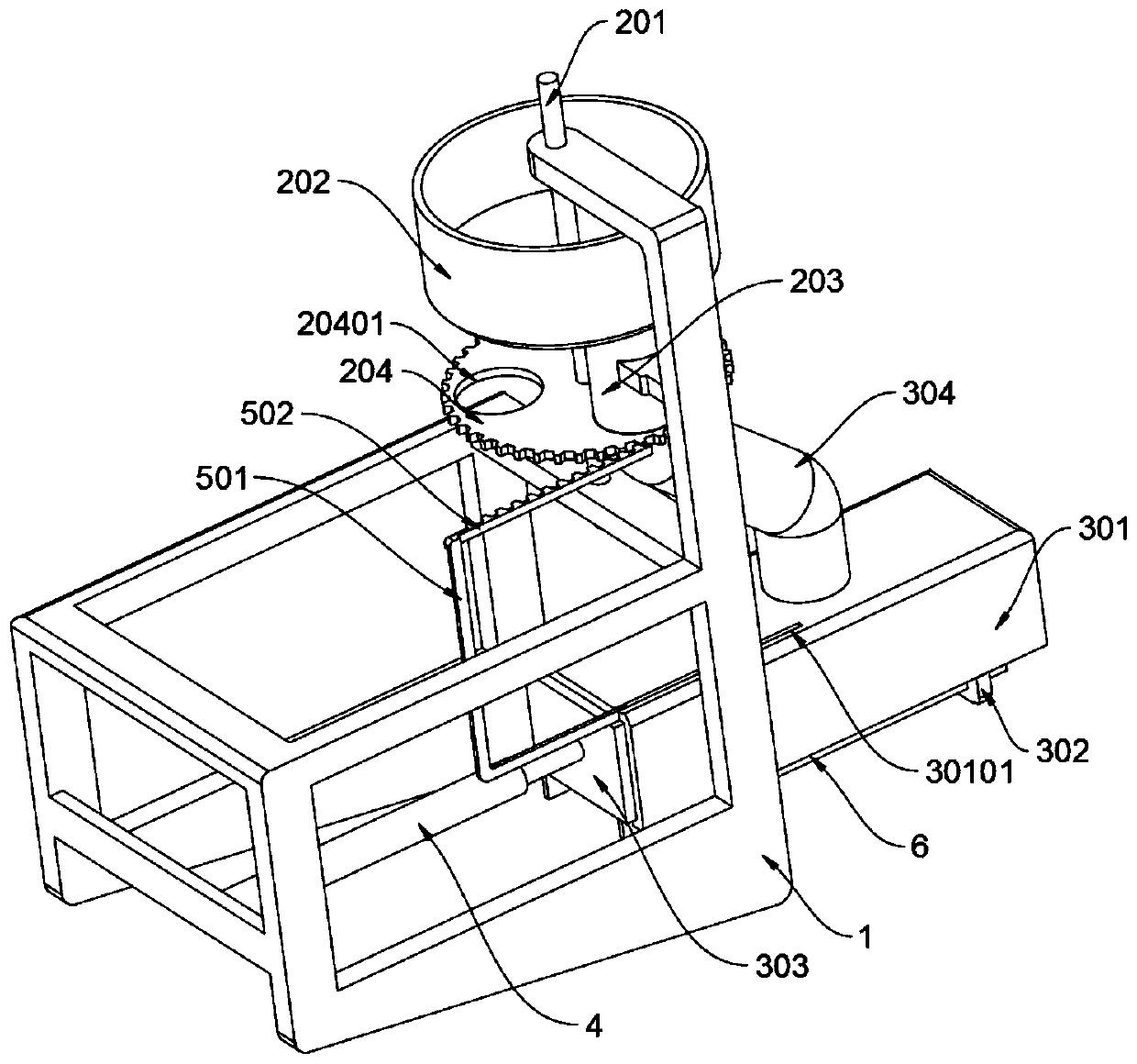

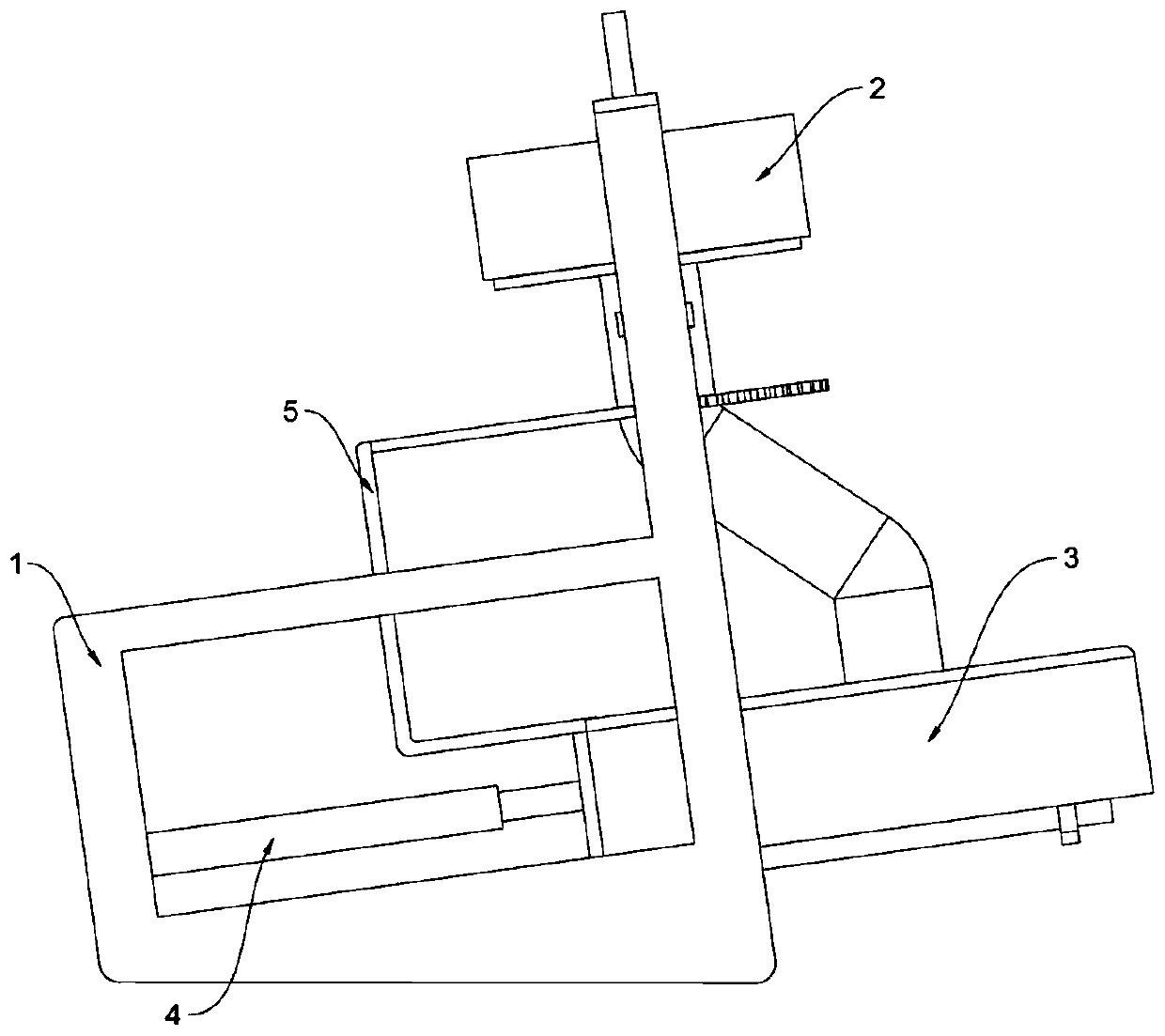

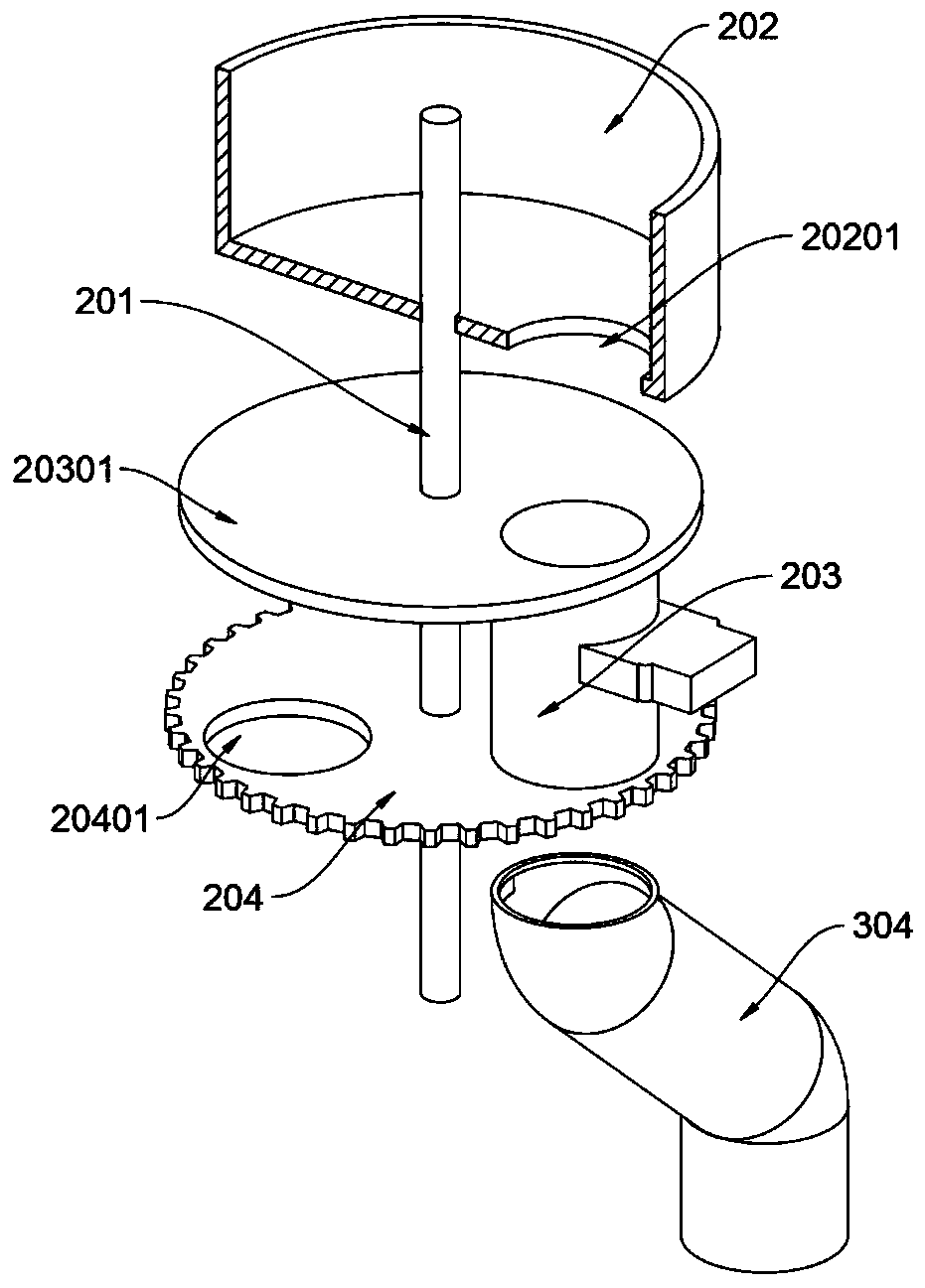

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The invention provides a hydraulic flattening machine for automatic collection and sorting of environment-friendly waste, which includes a frame body 1; a feed structure 2 is rotatably connected to the frame body 1, and an extruding structure 3 is welded on the frame body 1 , and a hydraulic telescopic rod 4 is fixedly connected to the frame body 1 by bolts; a transmission structure 5 is welded on the top surface of the extruded structure 3, and a shielding plate 6 is slidably connected to the bottom surface of the extruded structure 3; refer to for example Figure 5 with Figure 7 , the extrusion structure 3 also includes a connecting pipe 304; the top surface of the extrusion barrel 301 is welded with a connecting pipe 304, and the top of the connecting pipe 304 is in contact with the bottom end surface of the gear 204, and the top of the connecting pipe 304 is aligned with the extrusion barrel 301; the transm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap