Trailer special for accident automobile based on motor control lifting

A motor control and trailer technology, which is applied in the direction of vehicles used for freight, vehicles used for emergency repairs, and motor vehicles, which can solve the problems of large size, secondary collision, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

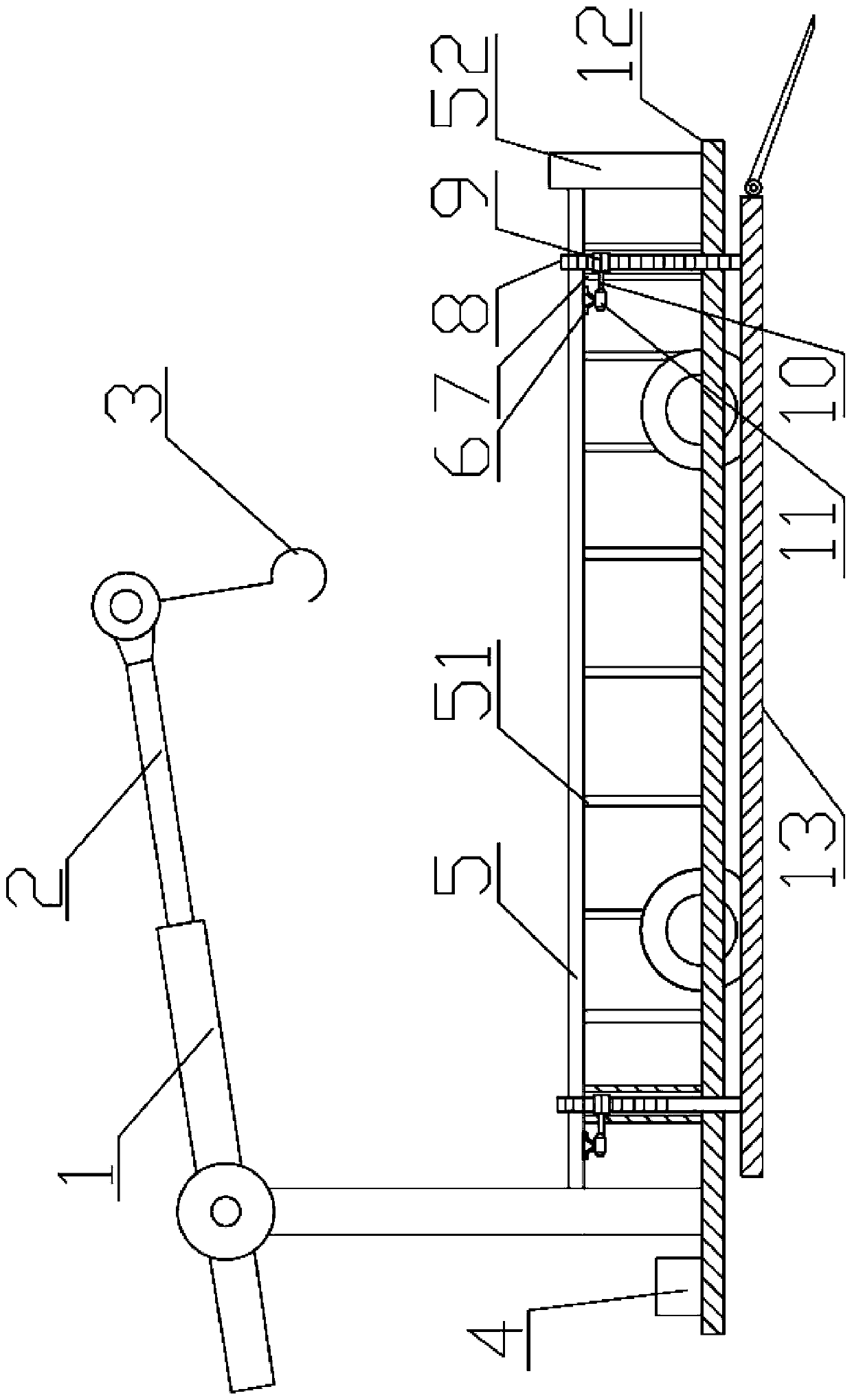

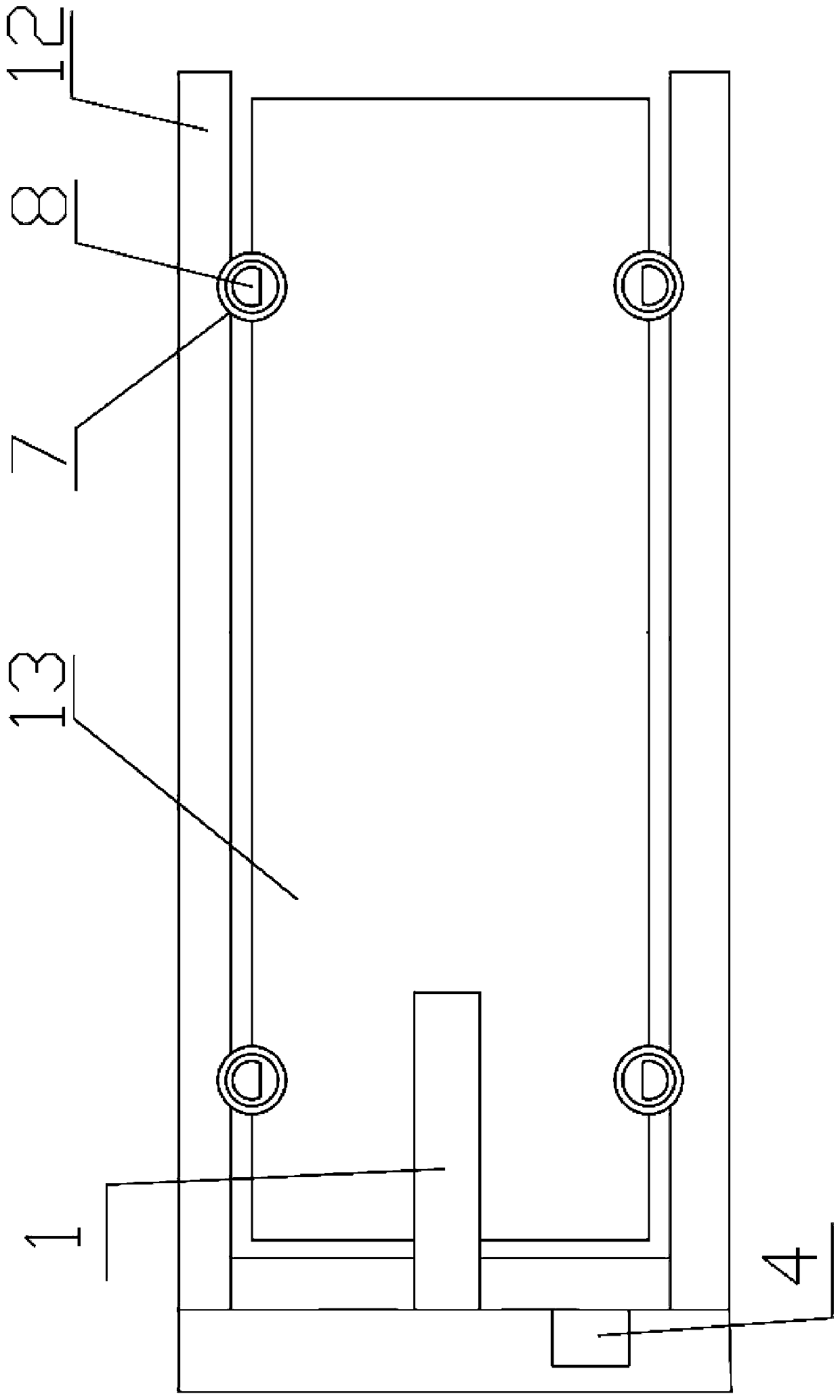

[0030] A motor-controlled special trailer for raising and lowering accident cars, including; 9 driving gear, 10 motor drive shaft, 11 driving motor, 12 trailer frame, 13 trailer floor.

[0031] The small crane 1 is connected with the small crane telescopic arm 2, the hook 3 is connected with the small crane telescopic arm 2 through a wire rope, the small crane 1 is fixed on the trailer frame 12, the hydraulic control mechanism 4 is fixed on the trailer frame 12, and the trailer guardrail 5 It is fixedly connected with the trailer frame 12, the upper end of the steel pipe 7 is fixed to the trailer guardrail 5, the lower end of the steel pipe 7 is fixed to the trailer frame 12, the circular rack 8 slides up and down in the steel pipe 7, and the lower end of the circular rack 8 is fixed to the trailer floor 13. Shaped rack 8 upper ends are rotationally connected with driving gear 9, and driving gear 9 is connected with motor drive shaft 10 with driving motor 11, and driving motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com