A layer-by-layer self-assembled chitin whisker-modified polylactic acid composite material and its preparation method and application

A technology of chitin whiskers and layer-by-layer self-assembly, which is applied in coatings, tissue regeneration, prostheses, etc., can solve problems such as weak force, difficulty in ensuring stable attachment of whisker layers, and difficulty in meeting individual requirements. The preparation process is simple and practical, the mechanical properties are controllable, and the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

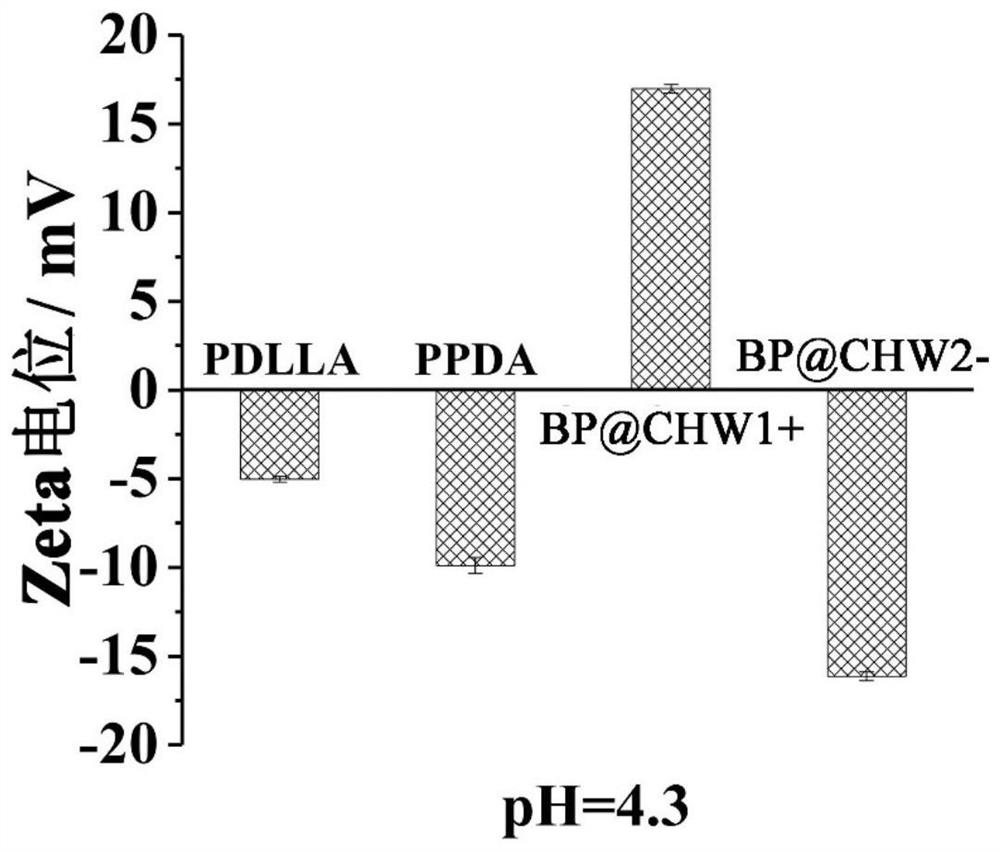

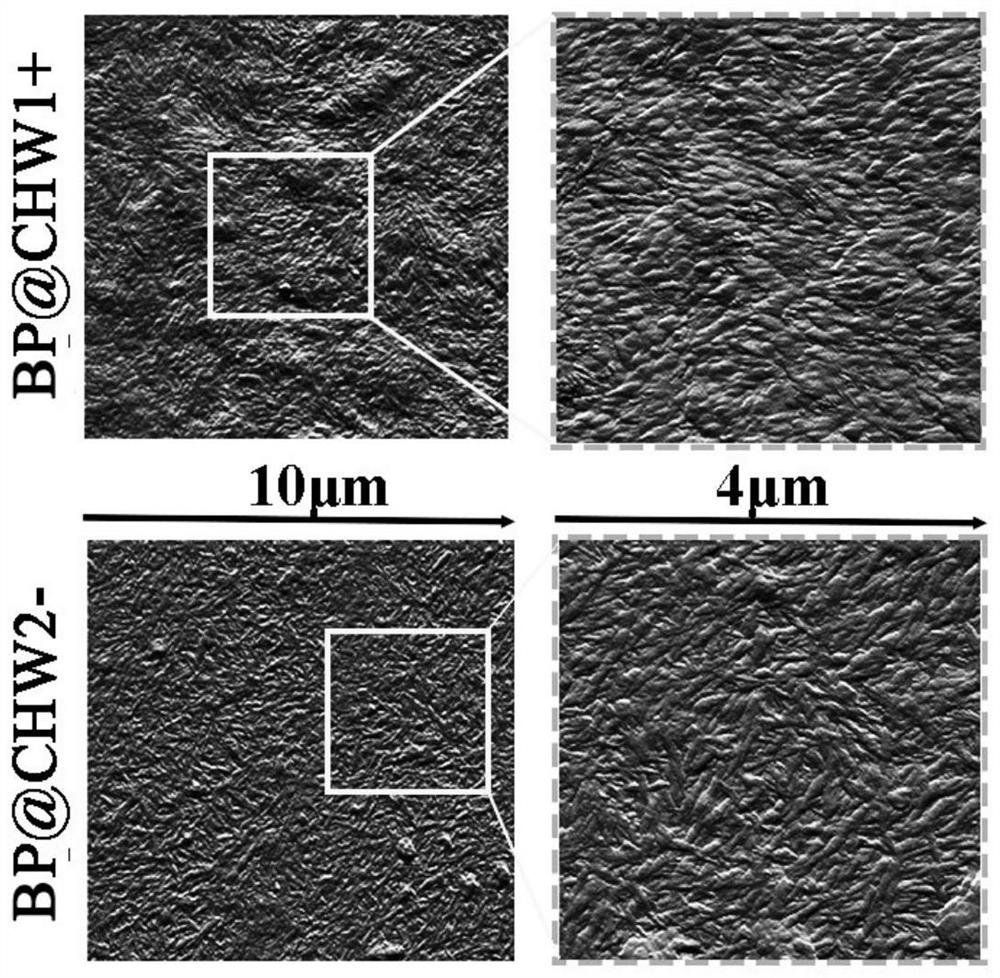

[0046] Example 1: Preparation of self-assembled chitin whisker-modified polylactic acid composites

[0047] Step 1: Weigh 1.0 part by mass of racemic polylactic acid (PDLLA) particles with a weight-average molecular weight of 15w, and pour it into 15 parts by volume of chloroform to dissolve. After stirring and dissolving for 8 h, the solution was subjected to ultrasonic treatment for 5 min to remove air bubbles in the solution, and then poured into a PTFE petri dish for molding. After volatilizing at room temperature for 12 h, it was put into a vacuum drying oven at 40° C. for vacuum drying for 6 h to completely remove the organic solvent, and a PDLLA film was obtained. The PDLLA membrane was further immersed in a 1.0 g / L dopamine hydrochloride Tris buffer solution (pH=8.5), taken out after 12 hours of reaction, washed and dried to obtain a polydopamine / polylactic acid composite membrane (PPDA).

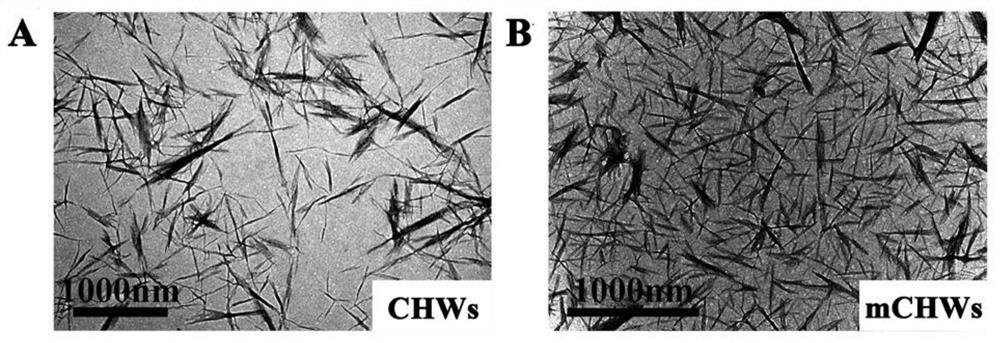

[0048] Step 2: Add 5 parts by mass of chitin powder to 1 mol / L HCl aqueous sol...

Embodiment 2

[0052] Example 2: Preparation of self-assembled chitin whisker-modified polylactic acid composites

[0053] Step 1: Weigh 5.0 parts by mass of racemic polylactic acid (PDLLA) particles with a weight-average molecular weight of 20w, and pour it into 80 parts by volume of tetrahydrofuran to dissolve. After stirring and dissolving for 10 h, the solution was subjected to ultrasonic treatment for 10 min to remove air bubbles in the solution, and then poured into a polytetrafluoroethylene petri dish for molding. After volatilizing at room temperature for 24 h, it was put into a vacuum drying oven at 40° C. for vacuum drying for 6 h to completely remove the organic solvent, and a PDLLA film was obtained. The PDLLA membrane was immersed in a 1.5 g / L dopamine hydrochloride Tris buffer solution (pH=8.5), taken out after 6 hours of reaction, washed, and dried to obtain a polydopamine / polylactic acid composite membrane (PPDA).

[0054] Step 2: Add 10 parts by mass of chitin powder to 3 m...

Embodiment 3

[0060] Example 3: Preparation of self-assembled chitin whisker-modified polylactic acid composite film

[0061] Step 1: Weigh 2.0 parts by mass of racemic polylactic acid (PDLLA) particles with a weight-average molecular weight of 30w, and pour it into 40 parts by volume of dichloromethane to dissolve. After stirring and dissolving for 12 h, the solution was subjected to ultrasonic treatment for 15 min to remove air bubbles in the solution, and then poured into a PTFE petri dish for molding. After volatilizing at room temperature for 12 h, it was put into a vacuum drying oven at 40° C. for vacuum drying for 6 h to completely remove the organic solvent, and a PDLLA film was obtained. The PDLLA membrane was further immersed in a 3.0 g / L dopamine hydrochloride Tris buffer solution (pH=8.5), taken out, rinsed and dried after the reaction for 18 hours to obtain a polydopamine / polylactic acid composite membrane (PPDA).

[0062] Step 2: Add 8 parts by mass of chitin powder to 2 mol / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com