Convex cavity type converter capable of reducing slag discharging amount in tapping process and tapping technology

A technology of tapping process and convex cavity is applied in the field of iron and steel metallurgy to avoid the formation of eddy currents, suppress the formation of eddy currents, and avoid initial slag formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

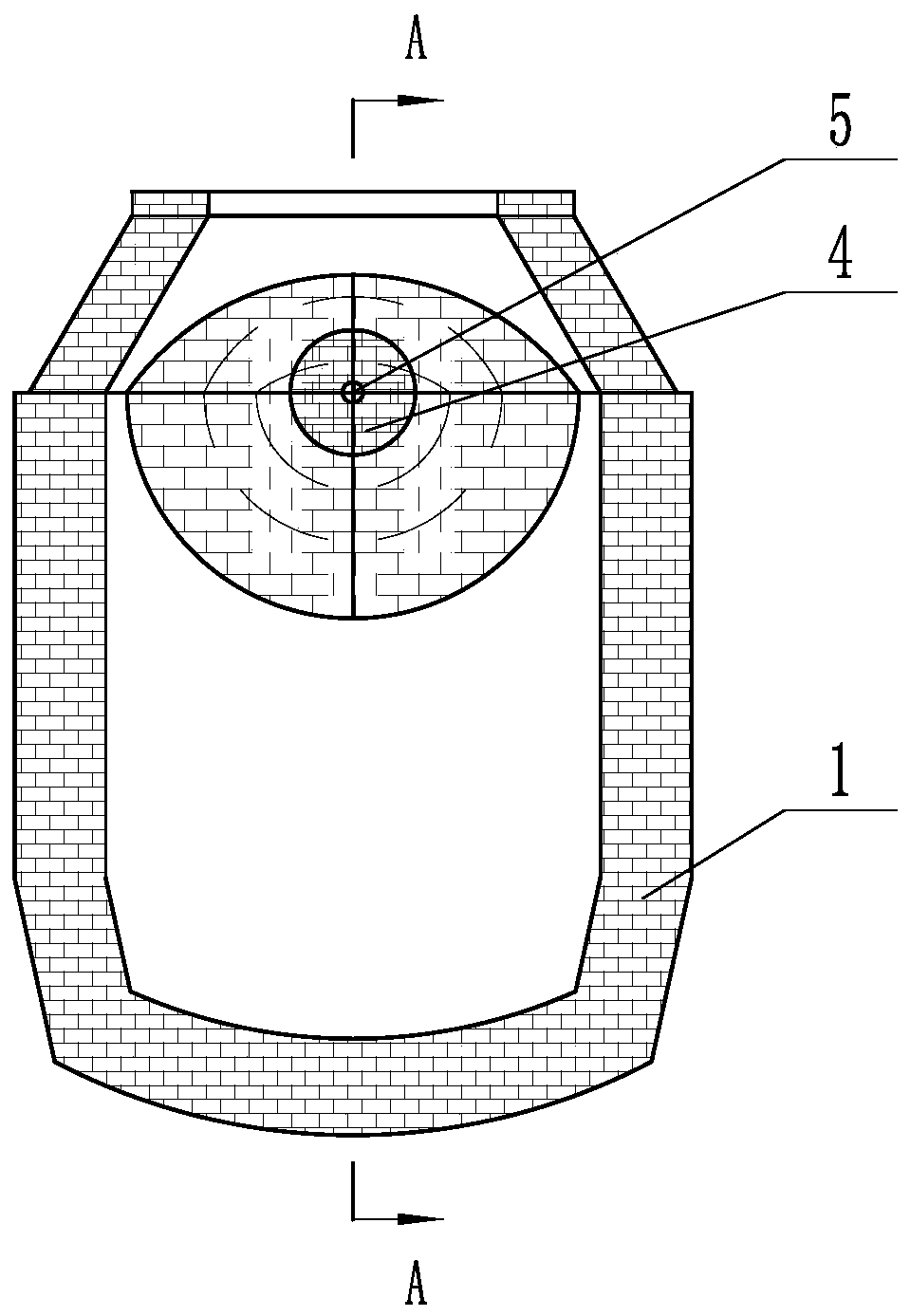

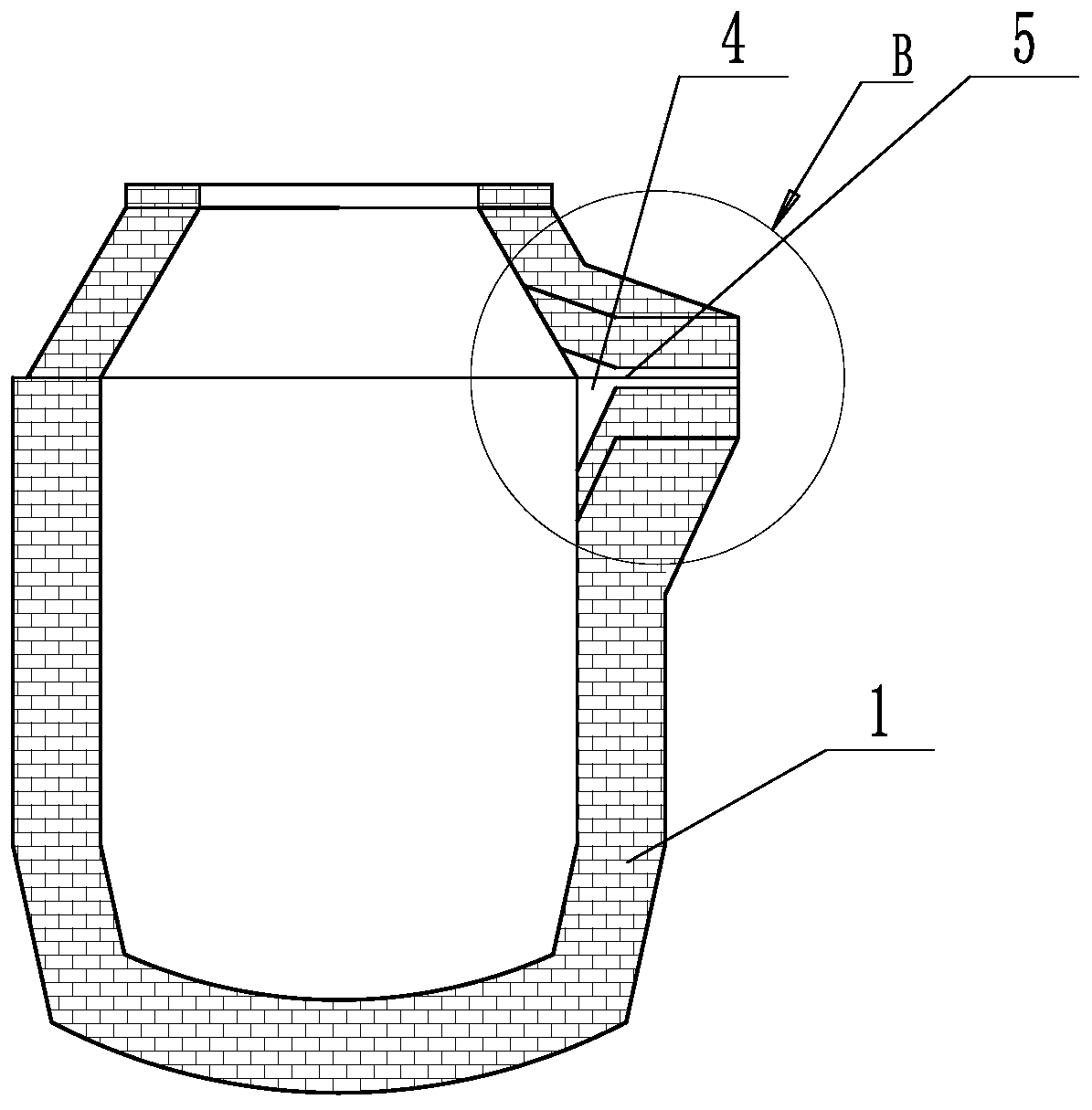

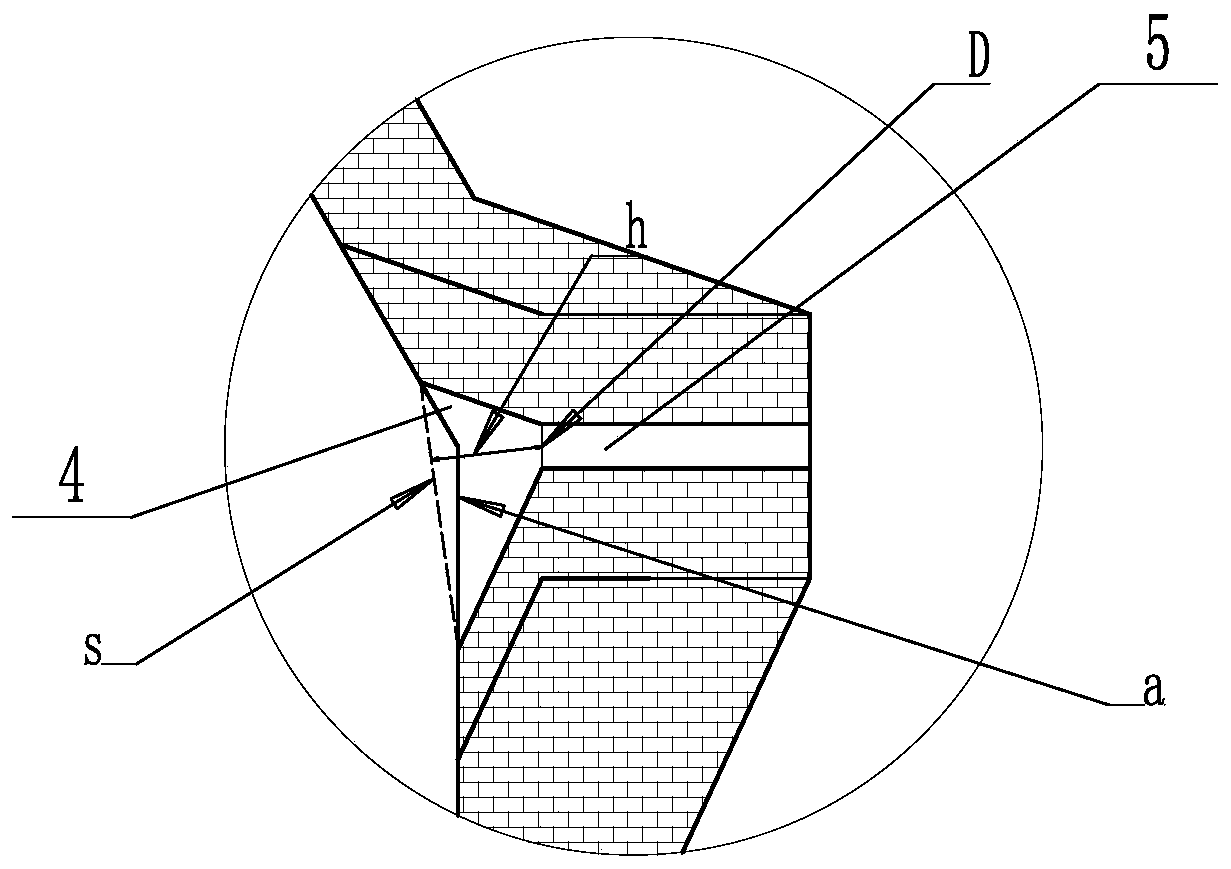

[0105] A steel mill optimized the inner cavity of the converter with a nominal capacity of 120 tons, and designed a convex cavity converter, in which the volume of the convex cavity 4 is 1.5m3, and the depth h of the convex cavity 4 is 0.4m. The area s of the intersection of the inner wall of the convex cavity 4 and the inner wall of the converter 1 is 4m 2 , Compared with before the improvement, the diameter of the tapping hole is increased by 10%, reaching 150mm, and the tapping time is reduced by 18%.

[0106] The tapping process of the convex cavity type converter that can reduce the slag amount in the tapping process of the present invention is:

[0107] Before the converter is smelted, insert the slag cap from the outside of the converter into the outlet 5 of the converter. After the converter is smelted, the steel is placed in the furnace by shaking. At the beginning of the furnace shaking, the slag cap blocks the instant slag, and the converter slag 3 floats to the con...

Embodiment 2

[0109] A steel mill optimized the inner cavity of the converter with a nominal capacity of 260 tons, and designed a convex cavity converter, in which the volume of the convex cavity 4 is 3m 3 , the depth h of the convex cavity 4 is 0.8m, and the area m of the intersection of the inner wall of the convex cavity 4 and the inner side wall of the converter 1 is 12m 2 , Compared with before the improvement, the diameter of the tapping hole is increased by 20%, reaching 240mm, and the tapping time is reduced by 31%.

[0110] The tapping process of the convex cavity type converter that can reduce the slag amount in the tapping process of the present invention is:

[0111] Before the converter is smelted, insert the slag cap from the outside of the converter into the outlet 5 of the converter. After the converter is smelted, the steel is placed in the furnace by shaking. At the beginning of the furnace shaking, the slag cap blocks the instant slag, and the converter slag 3 floats to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com