Anode device for preparing ni-sic composite coating on the inner wall of hollow parts

A composite coating and anode device technology, which is applied in the field of material processing, can solve problems such as uneven distribution of SiC particles, open circuit faults, and macro incompleteness of the coating, and achieve the effect of improving macro/micro uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

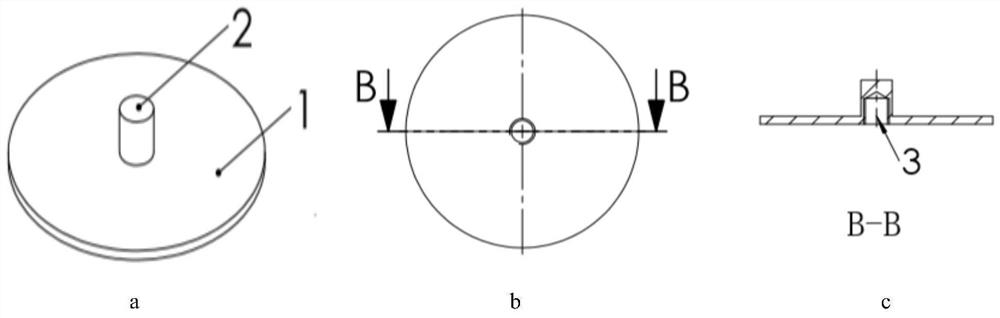

[0041] This embodiment is a nickel anode device with double-layer slits, which is used to prepare a Ni-SiC composite coating on the inner surface of a hollow part.

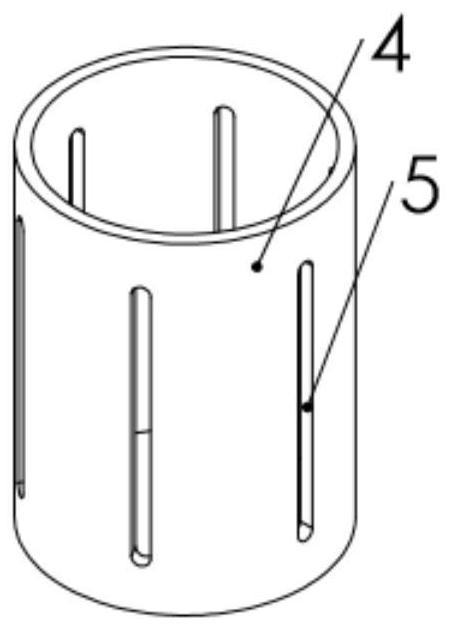

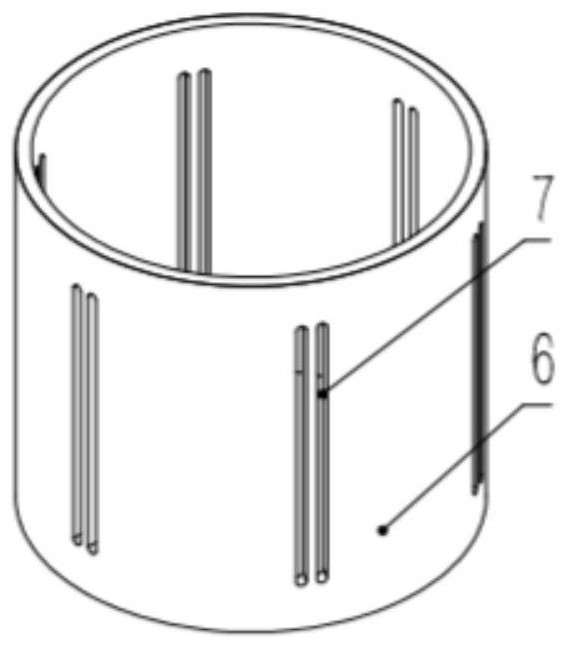

[0042] It includes a nickel anode top cover 1, an inner nickel anode tube 4 and an outer nickel anode tube 6. The nickel anode top cover, the inner nickel anode tube and the outer nickel anode tube are all made of 99.9% high-purity nickel.

[0043] The inner nickel anode tube 4 is located in the outer nickel anode tube 6, forming an anode tube body with a sandwich structure. The inner layer nickel anode tube in the anode tube body is coaxial with the outer layer nickel anode tube, and the positions of the inner layer anode slits 5 on the inner layer nickel anode tube wall are respectively positioned at the outer layer The positions of the outer layer anode slits 7 on the tube wall of the nickel anode tube are staggered.

[0044] The nickel anode top cover 1 is fixed on the end face of the upper end of the anode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com