A constant temperature crankcase with lubricating oil filtering function

A technology for lubricating oil tanks and crankcases, which is used in the control of lubricant temperature, installation/connection of lubricant purification devices, and lubricating parts. It can solve problems such as crankshaft heating, prolong service life, reduce impurities, and prevent The effect of extravasation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

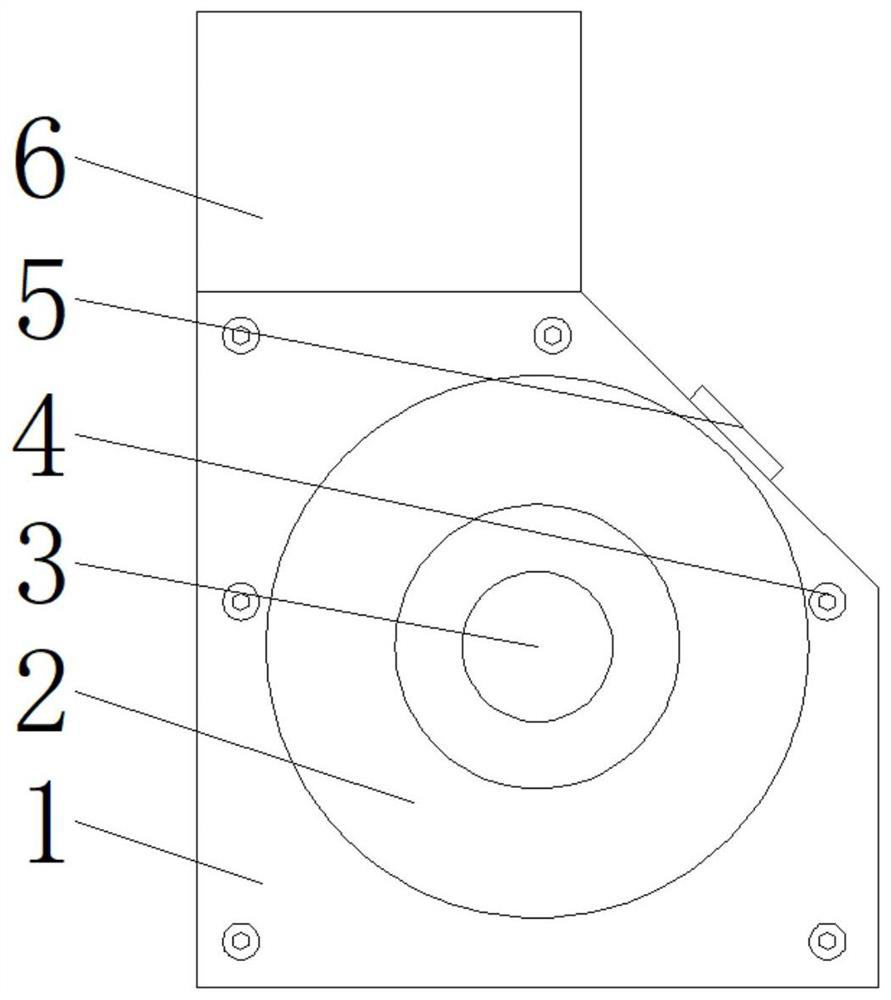

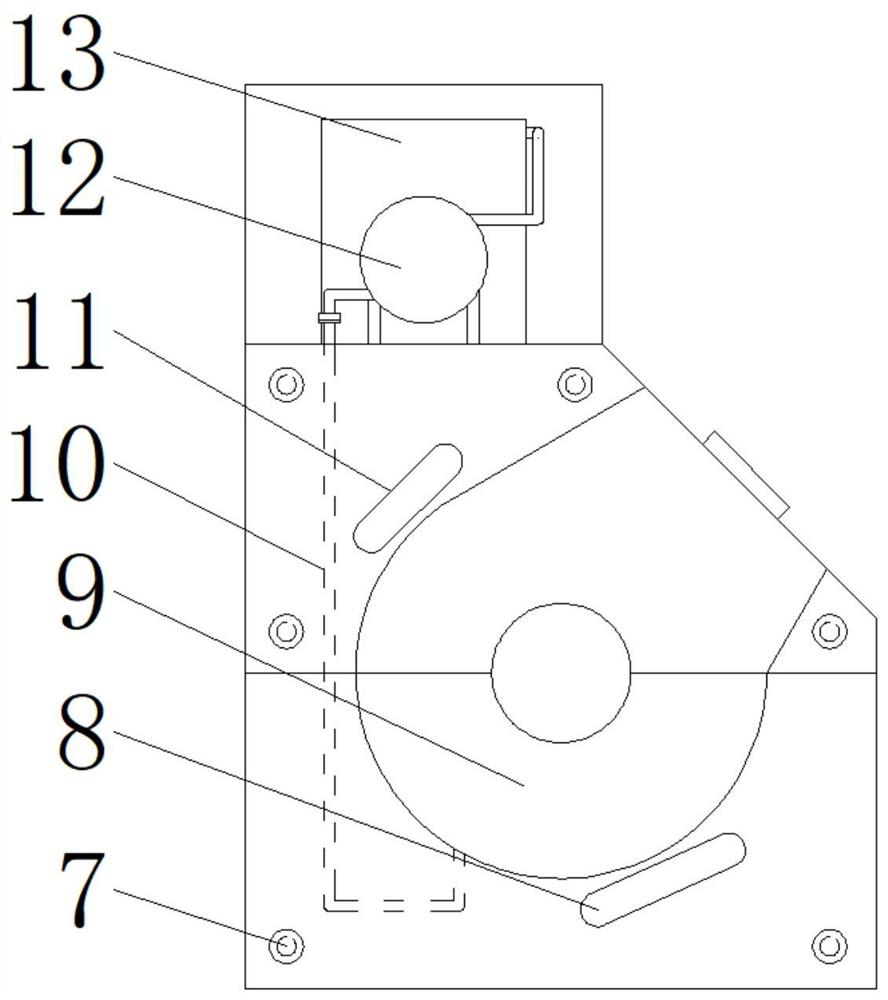

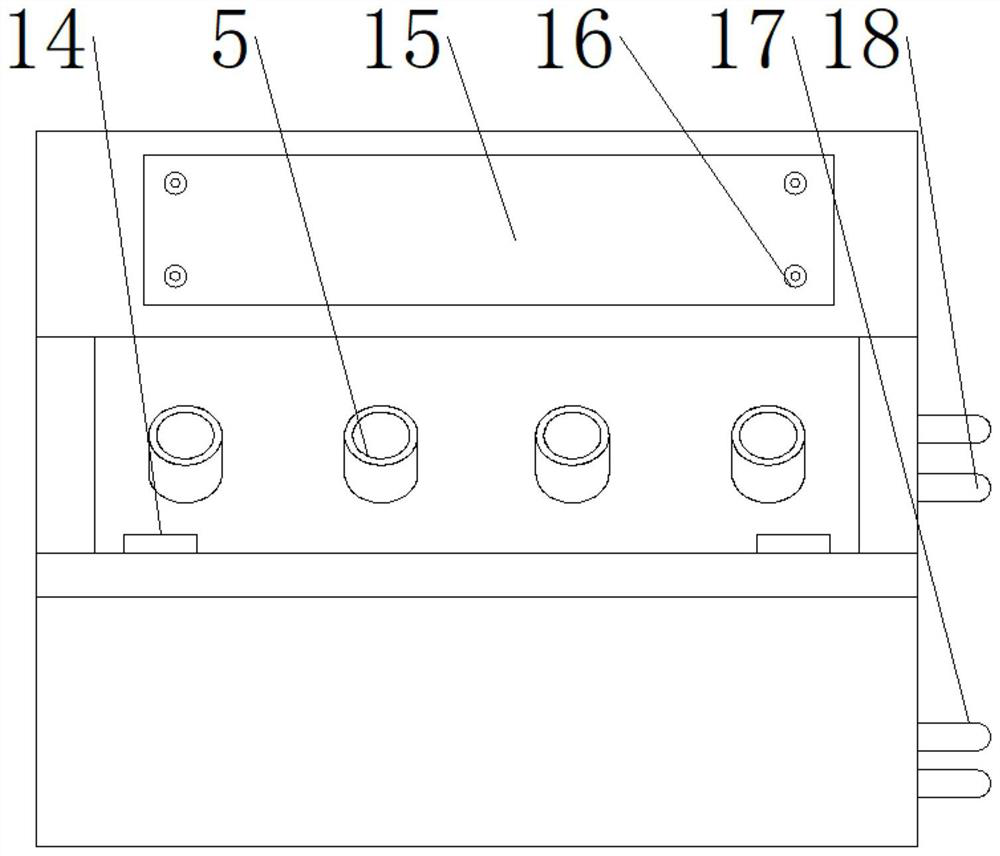

[0042] see Figure 1-4, a constant temperature crankcase with lubricating oil filtering effect, comprising an oil filter box 6, an upper crankcase is connected below the oil filter box 6, a lower crankcase is connected below the upper crankcase, and the upper crankcase and the lower A connecting flange is provided between the crankcases, and connecting bolts 14 are installed on the connecting flanges, and the upper crankcase and the lower crankcase are connected by the connecting bolts 14, and a lubricating oil tank 9 is excavated between the upper crankcase and the lower crankcase. , the top of the lubricating oil tank 9 is dug with an oil injection hole, and the bottom of the lubricating oil tank 9 is dug with an oil outlet hole, which is convenient for changing lubricating oil, and the two ends of the lubricating oil tank 9 are dug with a crankshaft hole 3, and crankshafts and crankshafts are installed in the crankshaft holes 3. A sealed bearing is installed at the hole 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com