Steel ladle accident rotation control valve stack

A technology for controlling valves and ladles, which is applied in the direction of manufacturing tools, servo motor components, mechanical equipment, etc. It can solve the problems of electrical system burnout, failure to use electrical control, and accidental rotation of ladles that cannot achieve the intended purpose, so as to prevent electrical power outages or The effect of burning and avoiding major production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the accompanying drawings, the present invention will be further described by examples.

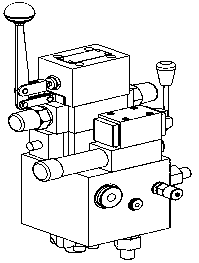

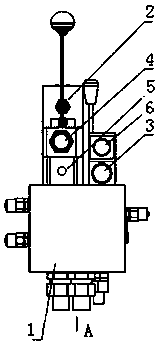

[0020] Refer to attached Figure 1-7 , a steel ladle accident rotation control valve group, including a manifold 1, a manual motor reversing valve 2, a pressure oil pipe joint 3, a superimposed one-way throttle valve 4, an overflow valve 5, a manual clutch reversing valve 6, a decompression Valve 8, hydraulic clutch 9, hydraulic motor 10, oil return pipe joint 11, leakage oil pipe joint 12, lower flange 13, upper flange 14 and clutch control oil pipe joint 15, and the front of the integrated block 1 is equipped with two stacks of left and right hydraulic pressure Valves, the top of the stack on the left is the manual motor reversing valve 2, the middle is the stacked one-way throttle valve 4, the bottom is the relief valve 5, the top of the stack on the right is the manual clutch reversing valve 6, and the bottom is the pressure reducing valve 8. The pres...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap