Sampling device for river sewage treatment and using method thereof

A sewage treatment and sampling device technology, applied in the direction of sampling devices, sampling, measuring devices, etc., can solve the problems of hidden safety hazards, inconvenient operation, troublesome use of sampling personnel, etc., and achieve the effect of improving safety and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

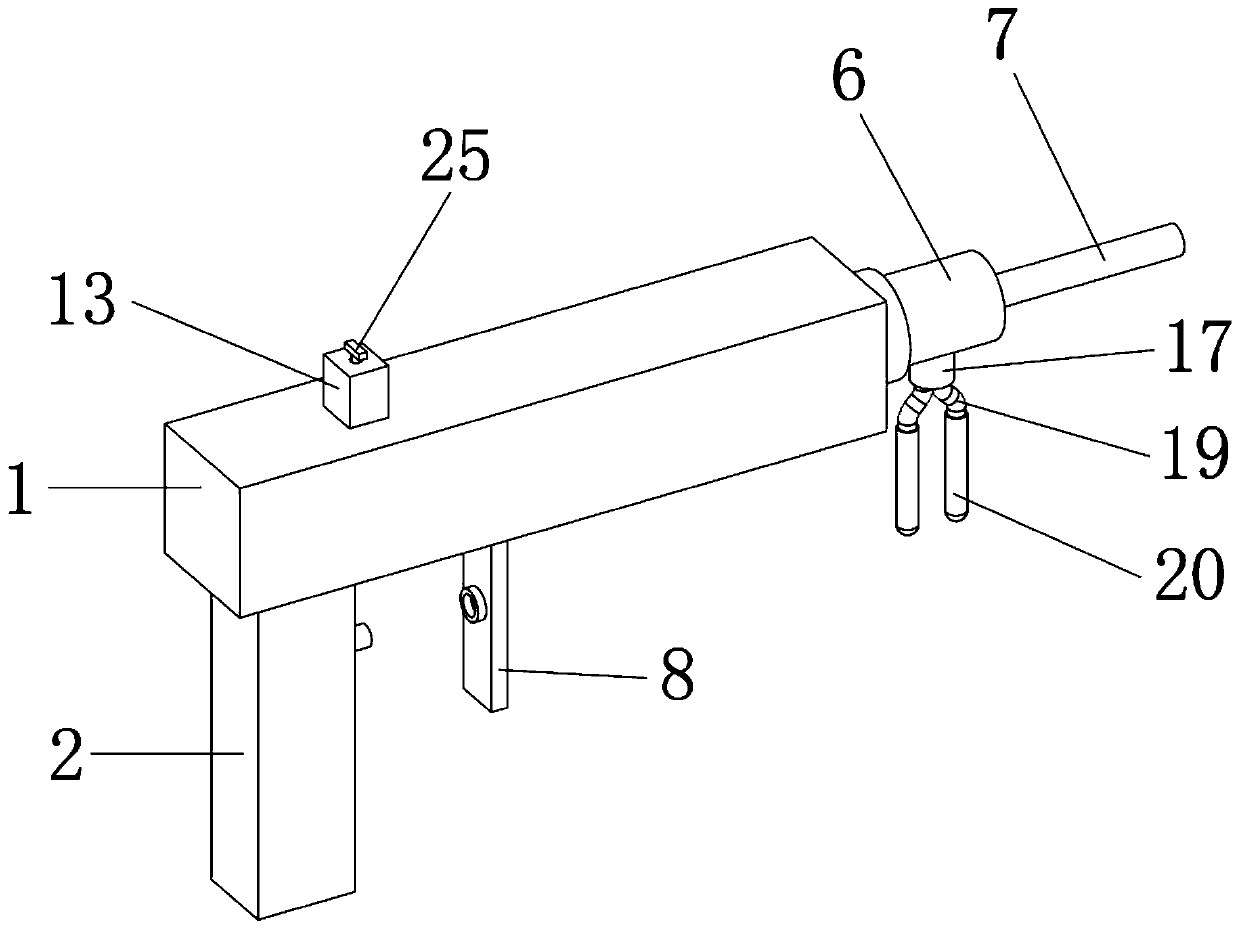

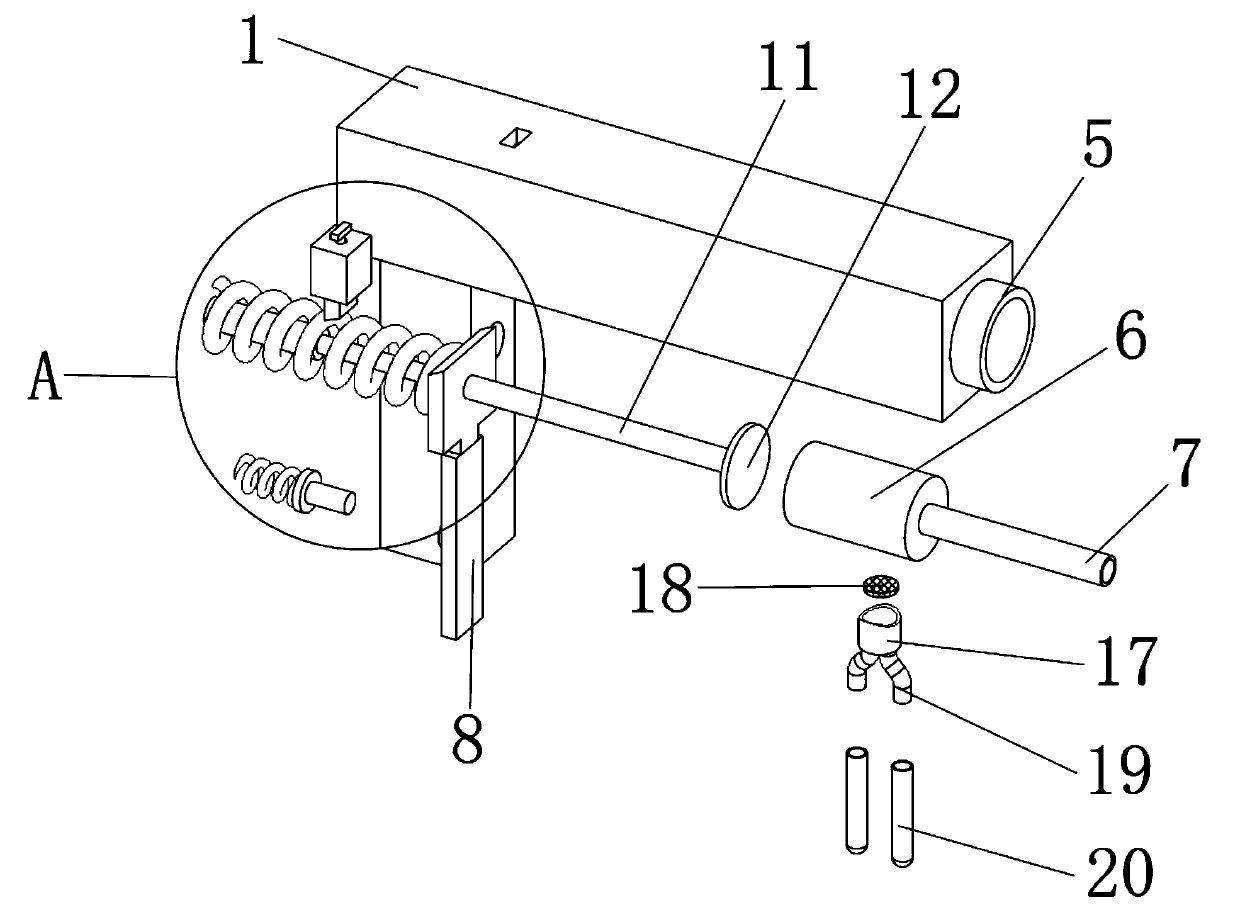

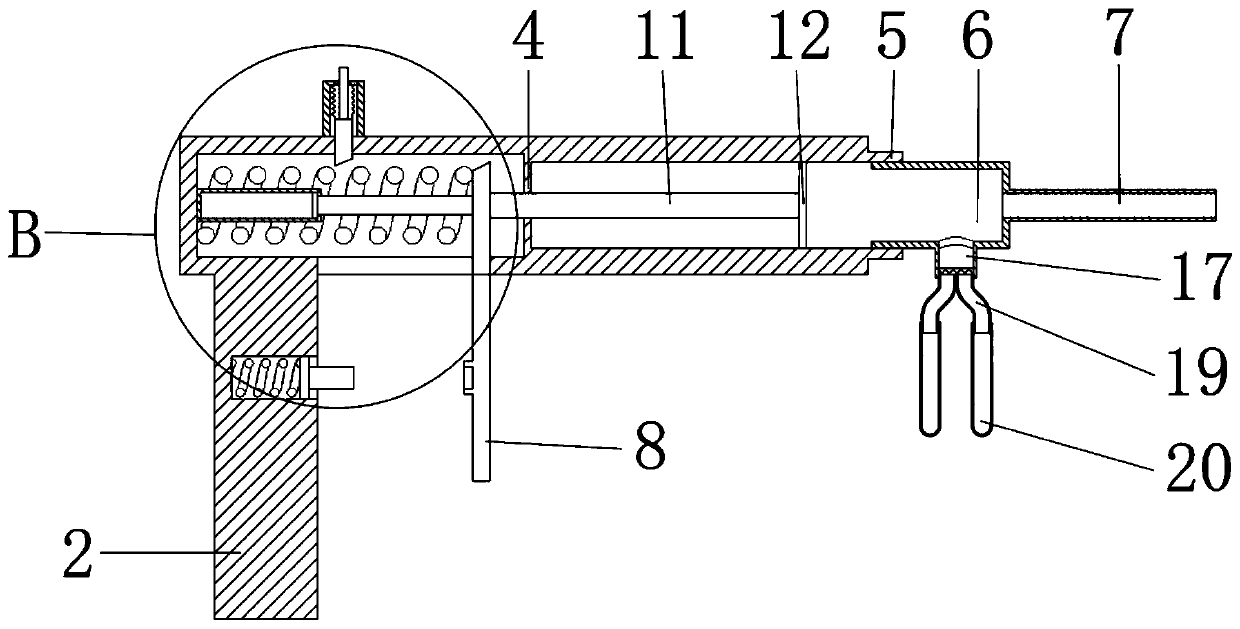

[0033] Embodiment 1. During the actual use of the present invention, the sampling personnel hold the limit vertical rod 2 to place the water inlet pipe 7 in the sewage, and then press the movable vertical plate 8. The top of the movable vertical plate 8 is in the first through groove Sliding in the middle, the movable vertical plate 8 drives the sliding plate 10 to move in the limiting square groove 3, the sliding plate 10 squeezes the limiting spring 9, the limiting spring 9 produces elastic deformation, the limiting spring 9 is compressed, and pushes the movable cross bar 23 Moving in the fixed sleeve 24, when the sliding plate 10 moves, the limit clamp 14 is pushed to move upward in the fixed groove 15, the limit clamp 14 squeezes the second spring 16, and the second spring 16 produces elastic deformation, and the second The spring 16 is compressed, and after the sliding plate 10 moves to the limit clamping plate 14, the second spring 16 restores elastic deformation and push...

Embodiment 2

[0034] Embodiment 2. When the sliding plate 10 moves, it drives the movable pull rod 11 to move. The movable pull rod 11 drives the piston plate 12 to move in the circular groove, and the sewage is pumped into the water collection pipe 6. The sewage enters the outlet pipe 17, and then the sewage passes through The filter screen 18 flows into the two shunt pipes 19 respectively, and then flows into the sampling test tube 20. After the sampling is finished, the sampling test tube 20 is rotated, the sampling test tube 20 is taken off, and the sewage in the sampling test tube 20 is taken out for detection, avoiding the sampling personnel It is inconvenient to squat on the bank of the river and put your hand into the sewage when sampling, which reduces the trouble of sampling personnel and improves the safety of the sampling device for sewage treatment. It is convenient and fast to operate, and it is convenient for rapid sewage sampling. When entering the diversion pipe 19 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com