CNC predictive maintenance system and method based on machine learning

A machine learning and maintenance system technology, applied in machine learning, transmission systems, instruments, etc., can solve problems such as single data storage means, small equipment storage capacity, and no deep data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

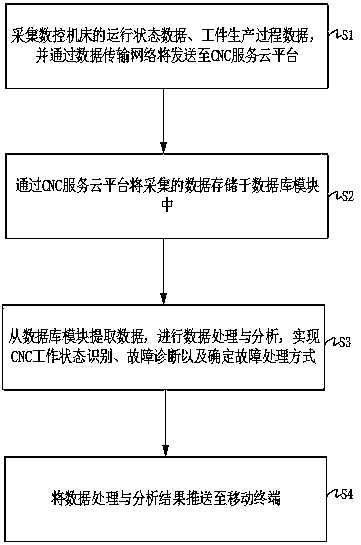

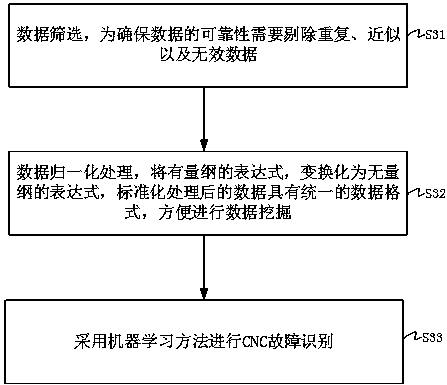

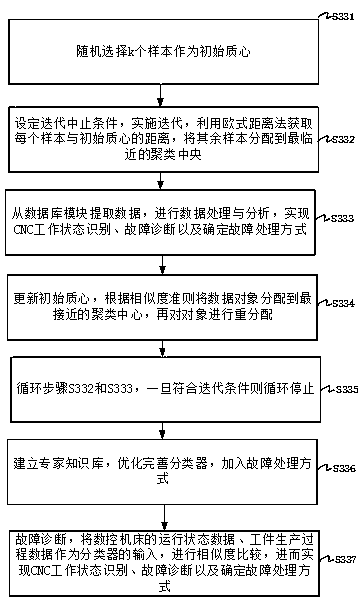

[0047] Below in conjunction with accompanying drawing and example the present invention will be further described:

[0048] see figure 1 , a CNC predictive maintenance system based on machine learning, including: CNC status monitoring system, data transmission network, CNC service cloud platform and mobile terminal. The CNC state monitoring system is used for the collection and monitoring of the running state data of the CNC machine tool and the workpiece production process data, and sends the information data to the CNC service cloud platform through the data transmission network; the data transmission network is used for The collected data is sent to the CNC service cloud platform through wireless communication methods such as WiFi, ZigBee and GPRS; the CNC service cloud platform is used to store, model and analyze the collected data; the mobile terminal, Used to display collected data and analysis results on smartphones and tablets.

[0049] Further, the CNC state monitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com