Plastic substrate thin-film battery with front electrode being led to other side of battery and preparation method

A technology of thin-film batteries and front electrodes, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems affecting the efficiency of batteries and components, limited heat resistance of the substrate, and large electrode shading area, so as to avoid loss of battery efficiency, Effect of reducing welding damage and reducing shading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

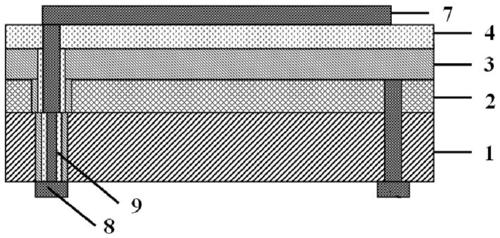

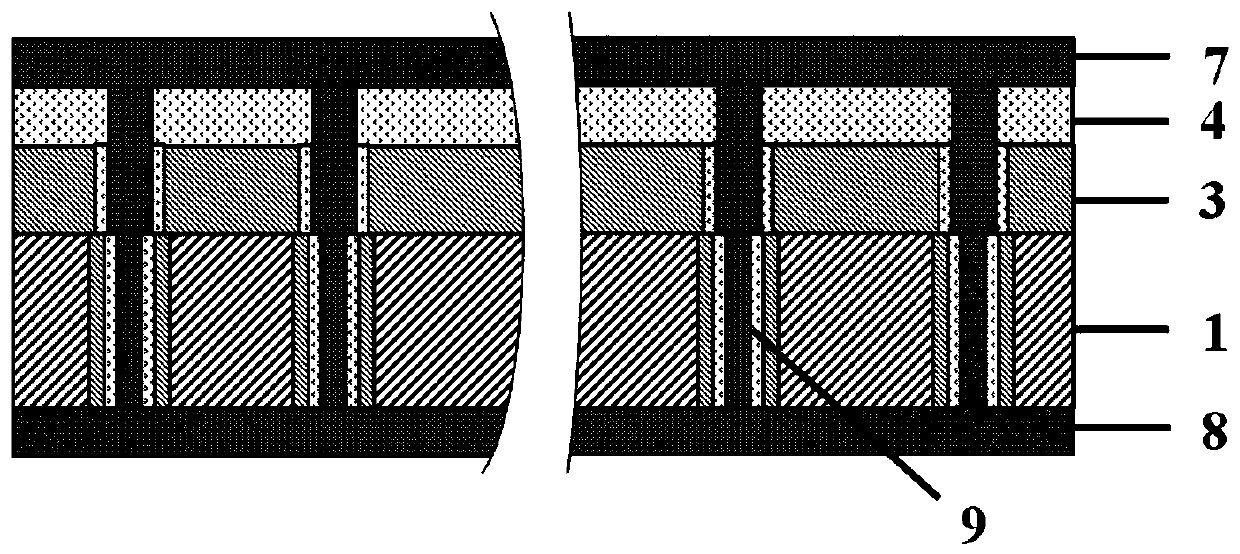

[0030] Step 1: Select 25m polyimide material as the substrate material of the plastic substrate thin-film solar cell, put the rolled polyimide substrate into the magnetron sputtering equipment, perform plasma purging, and clean the polyimide surface, and a silver / zinc oxide layer is sputtered in a high vacuum at 200° C. to form a back electrode 2 .

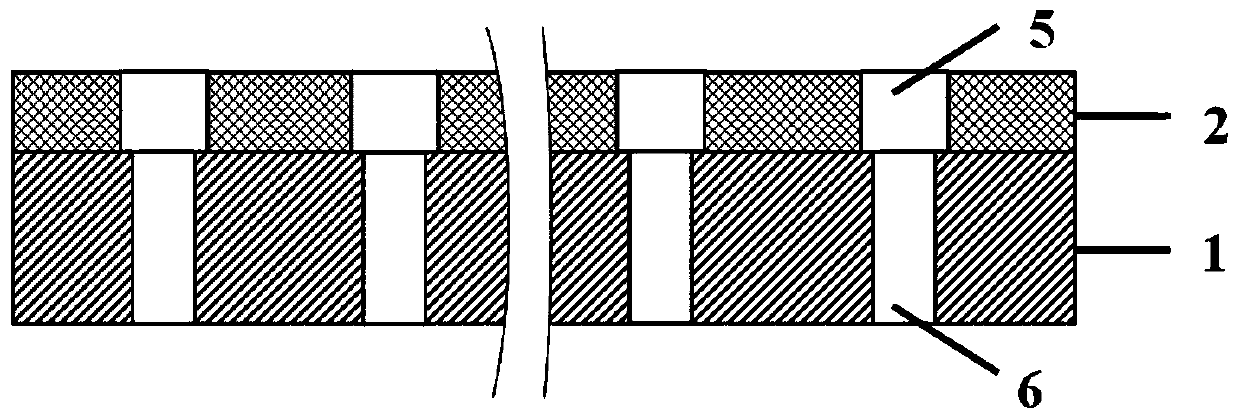

[0031] Step 2: preparation of back electrode stripping grooves 5: using a 1064 nm laser to etch the back electrode 2 to form several stripping grooves 5 with a width of 100 μm.

[0032] Step 3: Carry out mechanical microholes 6 in the back electrode stripping groove 5, and the diameter of the microholes 6 is 60 μm.

[0033] Step 4: Carry out dust removal and adsorption on the laser and mechanically processed materials to remove the residual dust on the materials.

[0034] Step 5: using PECVD (Plasma Enhanced Chemical Vapor Deposition, plasma enhanced chemical vapor deposition) equipment to prepare the battery active layer 3 . Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com