Method for preparing high-foaming egg white by gelatin gel assisted salted egg white desalination

A gelatin gel, gelatin technology, applied in application, food science, food ingredients, etc., can solve the problems of egg white protein denaturation, difficulty in large-scale promotion and practical application, complicated steps, etc., and achieve high foaming and foaming. The effect of stability, ease of large-scale production, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

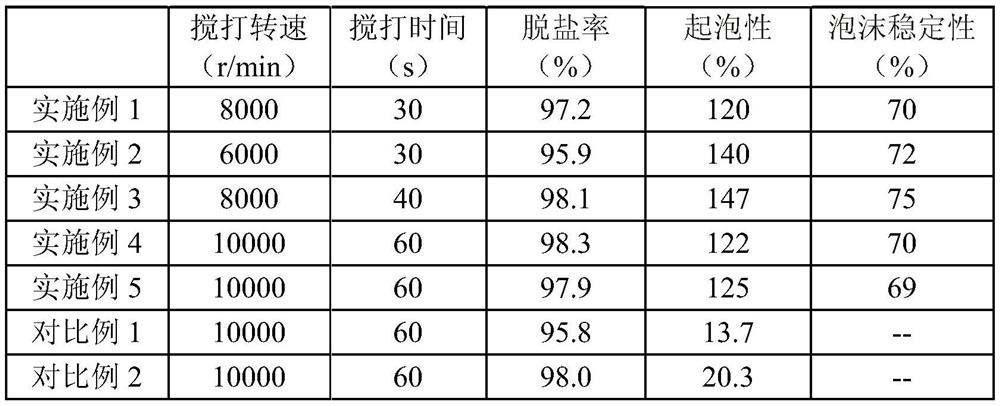

Embodiment 1

[0026] The method of using gelatin gel to assist desalination of salted egg white to prepare high-foaming egg white in this embodiment specifically includes the following steps:

[0027] (1) Separate the egg yolk from the egg white of the salted egg, remove the ligature with tweezers, stir the salted egg white with an electric mixer at a speed of 1000r / min for 30s and then let it stand for 30 minutes, filter the salted egg white with a filter cloth to obtain a uniform salted egg white liquid ;

[0028] (2) Mix the salted egg white solution in step (1) with the prepared 4% gelatin solution in a ratio of 1:1 (equal volume), stir and mix thoroughly for 30 minutes, then put it in a refrigerator at 4°C for 12 hours to obtain egg white- gelatin gel;

[0029] (3) Cut the gel prepared in step (2) into about 1cm 3 Large or small blocks, soak in clean water for 3 hours to remove the salt in the gel, drain the water to obtain the desalted egg white-gelatin gel, that is, desalted egg wh...

Embodiment 2

[0032] The method of using gelatin gel to assist desalination of salted egg white to prepare high-foaming egg white in this embodiment specifically includes the following steps:

[0033] (1) Separate the egg yolk from the egg white of the salted duck egg, remove the ligature with tweezers, stir the salted egg white with an electric mixer at a speed of 1000r / min for 30s and then let it stand for 30 minutes, filter the salted egg white with a filter cloth to obtain a uniform salted egg white liquid ;

[0034] (2) Mix the salted egg white solution in step (1) with the prepared 6% gelatin solution at a ratio of 1:1 (equal volume), stir and mix thoroughly for 120 minutes, then put it in a refrigerator at 4°C for 12 hours to prepare egg white - gelatin gel;

[0035] (3) Cut the gel prepared in step (2) into about 2cm 3 size, soak in water for 4 hours to remove the salt in the gel, drain the water to obtain the desalted egg white-gelatin gel;

[0036] (4) Heat and dissolve the des...

Embodiment 3

[0038] The method of using gelatin gel to assist desalination of salted egg white to prepare high-foaming egg white in this embodiment specifically includes the following steps:

[0039] (1) Separate the egg yolk from the egg white of the salted quail eggs, remove the ligature with tweezers, stir the salted egg white with an electric mixer at a speed of 1000r / min for 30s and then let it stand for 30 minutes, filter the salted egg white with a filter cloth to obtain a uniform salted egg white liquid;

[0040] (2) Mix the salted egg white solution in step (1) with the prepared 8% gelatin solution at a ratio of 1:1 (equal volume), stir and mix thoroughly for 60 minutes, then put it in a refrigerator at 4°C for 12 hours to prepare egg white - gelatin gel;

[0041] (3) Cut the gel prepared in step (2) into 1.5cm 3 size, soak in clean water for 5 hours to remove the salt in the gel, drain the water to obtain the desalted egg white-gelatin gel;

[0042] (4) Heat and dissolve the d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap