Forming manufacturing process for clutch discs

A clutch plate and manufacturing process technology, which is applied in the field of clutch plate forming and manufacturing technology, can solve the problems of low usage of forming devices, affecting the forming quality of glass fiber filaments, and damage to glass fiber filaments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

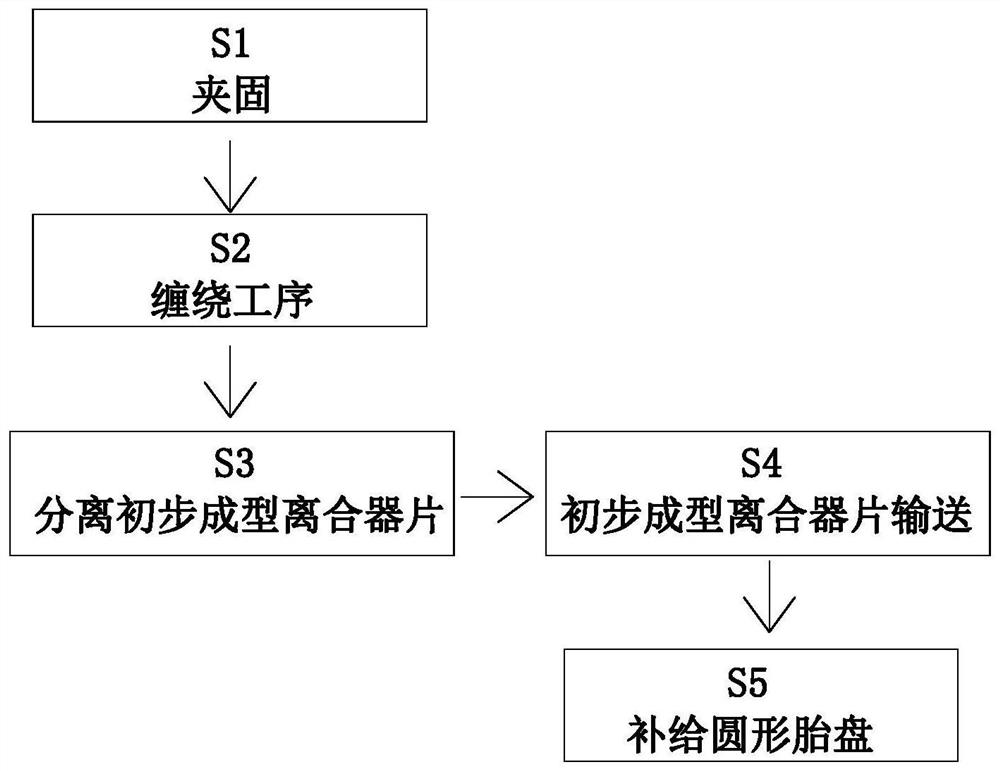

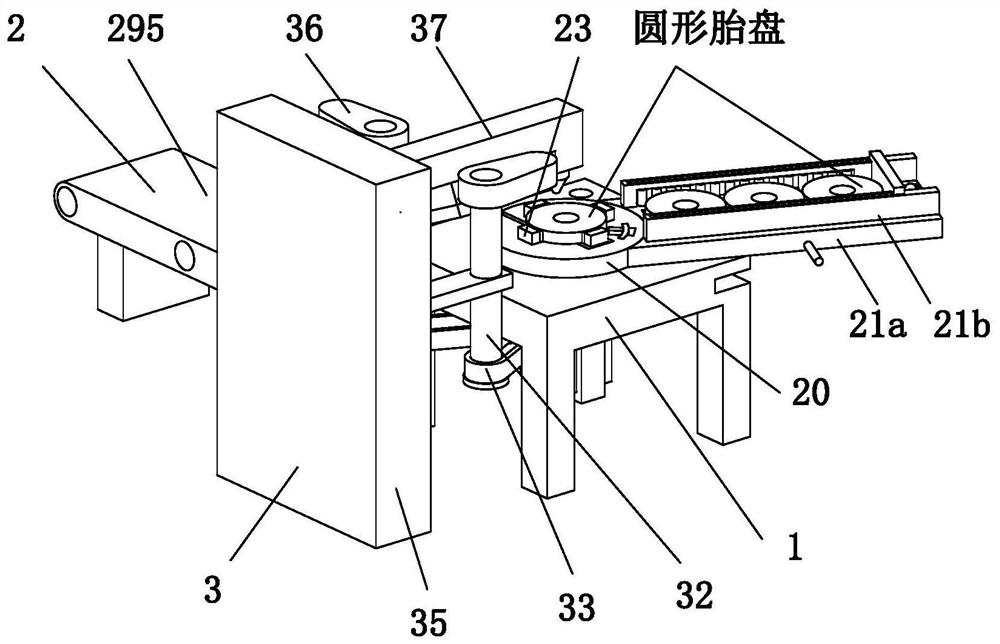

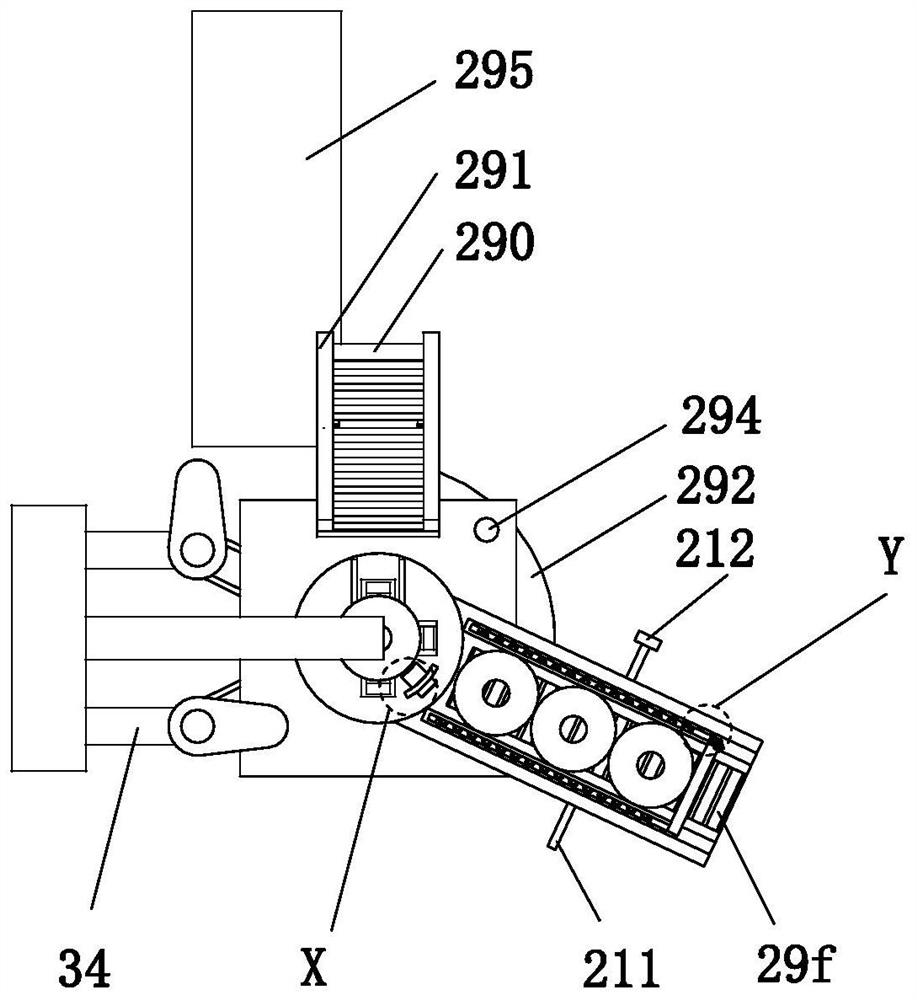

[0040] like Figure 1 to Figure 10 As shown, a clutch plate forming manufacturing process uses a clutch plate forming manufacturing device, the clutch plate forming manufacturing device includes a workbench 1, a pinching mechanism 2 and a winding mechanism 3, and is carried out by using the above-mentioned clutch plate forming manufacturing device. The specific molding and manufacturing process of the clutch plate is as follows:

[0041] S1. Clamping: Driven by the No. 1 electric slider 22, the connected splint 23 moves upward for a corresponding distance, and the splints 23 cooperate with each other to clamp the circular placenta to the upper end surface of the round table 20;

[0042] S2. Winding process: the motor 30 drives the round table 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com