Bean curd skin finishing machine

A technology of bean curd skin and sorting machine, which is applied in the direction of thin material processing, cheese substitutes, and delivery items, etc., can solve the problem of low efficiency of bean curd skin sorting, and achieve the effect of automatic erection operation and high stacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

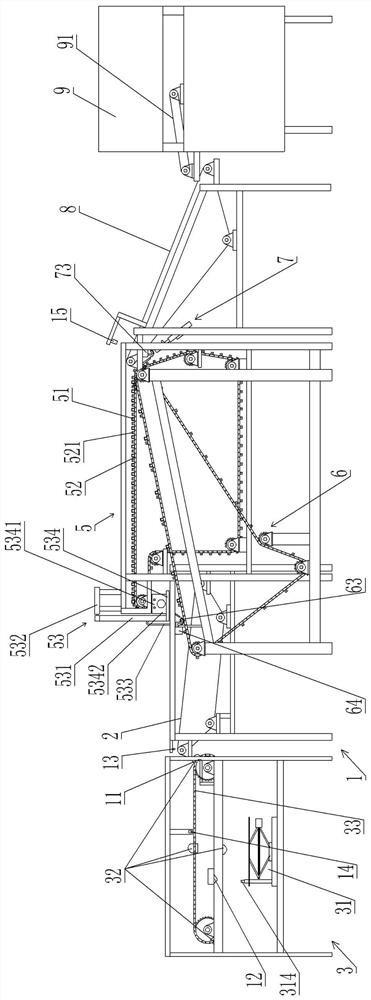

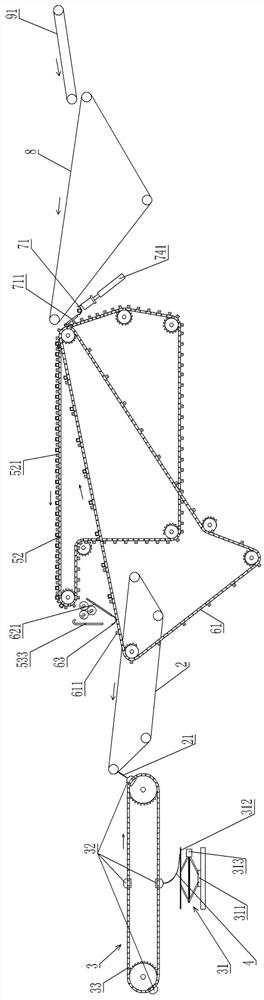

[0032] A kind of tofu skin finishing machine, please refer to Figure 1 to Figure 6 .

[0033] The bean curd skin finishing machine provided by the embodiment of the present invention includes a frame 1, and the frame 1 is used to install and support other components, mechanisms and devices of the bean curd skin finishing machine, so that each component, mechanism and device can cooperate with each other to realize corresponding functions Overall. In this embodiment, the frame 1 is designed as a split type, and it can also be designed as an integral type in other embodiments.

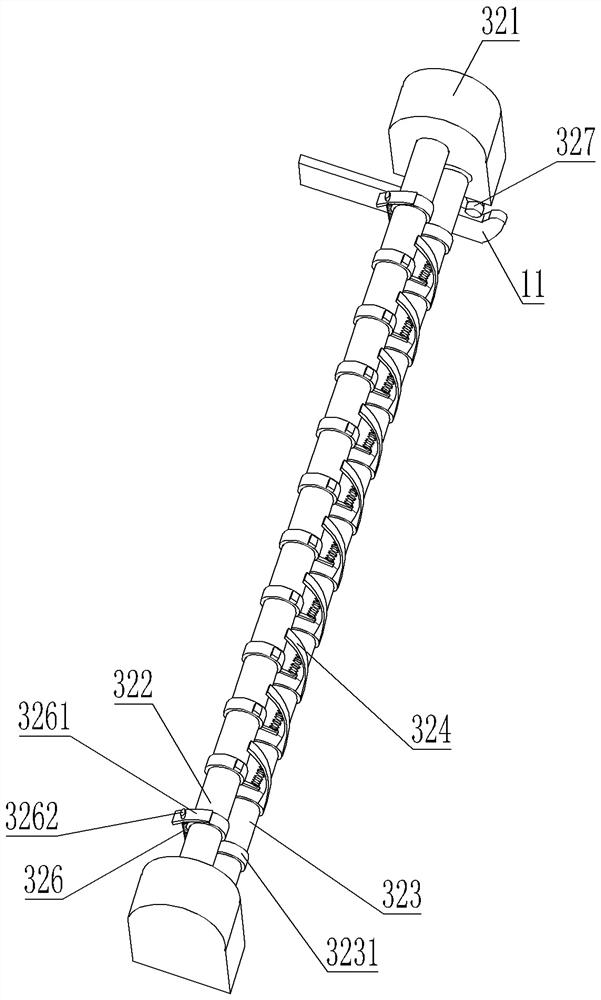

[0034] Such as figure 1 and figure 2 As shown, a bean curd skin conveyor belt 2 is installed on the frame 1, and a bean curd skin stacking device 3 located beside the bean curd skin conveyor belt 2 is installed. The skin is sent to the bean curd skin stacking device 3, and the bean curd skins are stacked one by one by the bean curd skin stacking device 3. The transmission motor of the mechanical k...

Embodiment 2

[0076] A kind of tofu skin finishing machine, please refer to Figure 1 to Figure 7 .

[0077] The difference from Embodiment 1 is that the tofu skin flattening mechanism 53 in the tofu skin finishing machine provided by the embodiment of the present invention uses a driving mechanism to drive the support rod 534 to swing at a certain angle, so that the take-up rod 51 rolls off from the support rod 534 .

[0078] Concretely, this driving mechanism comprises a vertical rod 535 and a cylinder 536. The middle part of the support rod 534 is hinged on the top of the vertical rod 535, and the rear end is hinged on the top of the cylinder 536. The vertical rod 535 and the cylinder 536 are installed on the frame where the tofu skin conveyor belt 2 is superior. After the bean curd skin 4 on the pole 51 falls, the piston rod of the operating cylinder 536 is retracted, and the supporting rod 534 can be pulled to swing a certain angle clockwise, so that the pole 51 comes off, and the ne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap