Lifting device for building construction

A lifting device and construction technology, applied in the direction of lifting devices, lifting frames, lifting equipment safety devices, etc., can solve the problems of difficult installation, waste of manpower, low efficiency, etc., and achieve easy movement and installation, high practicability, and lifting wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

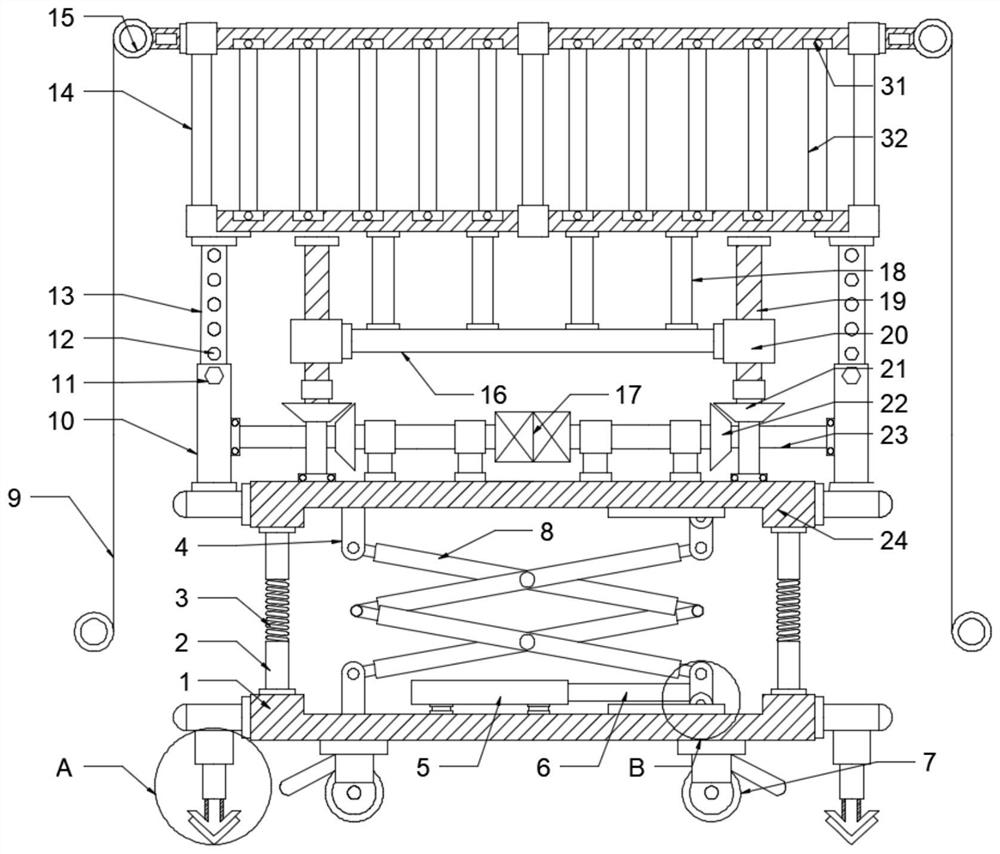

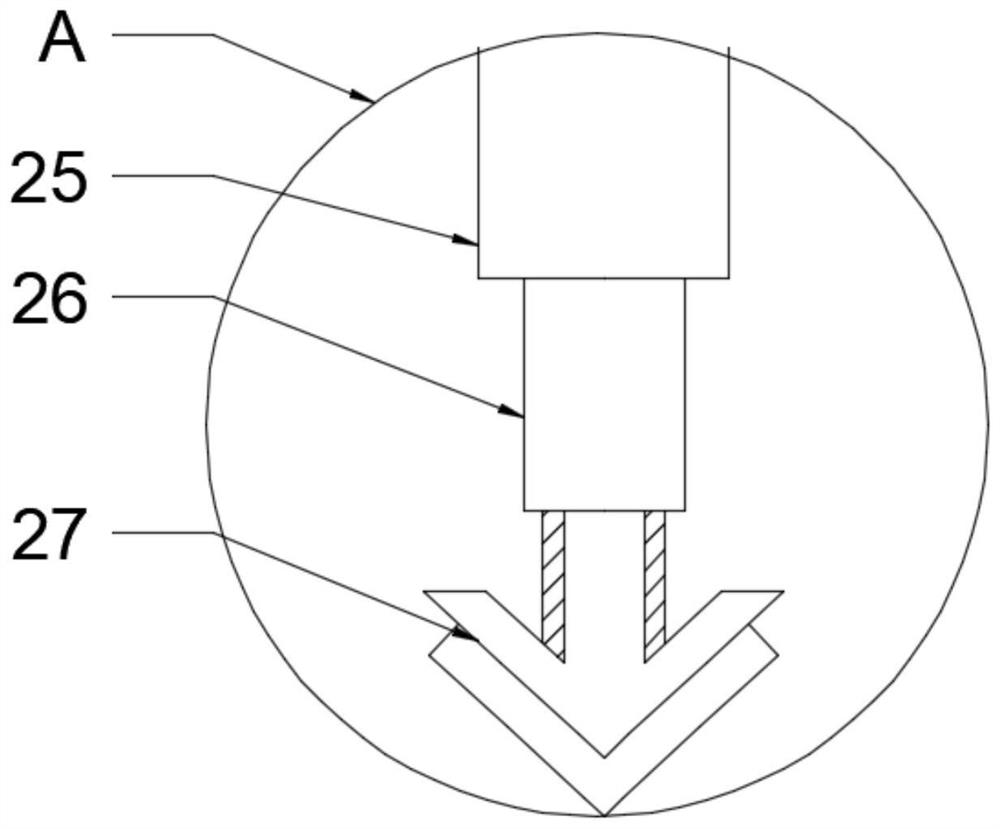

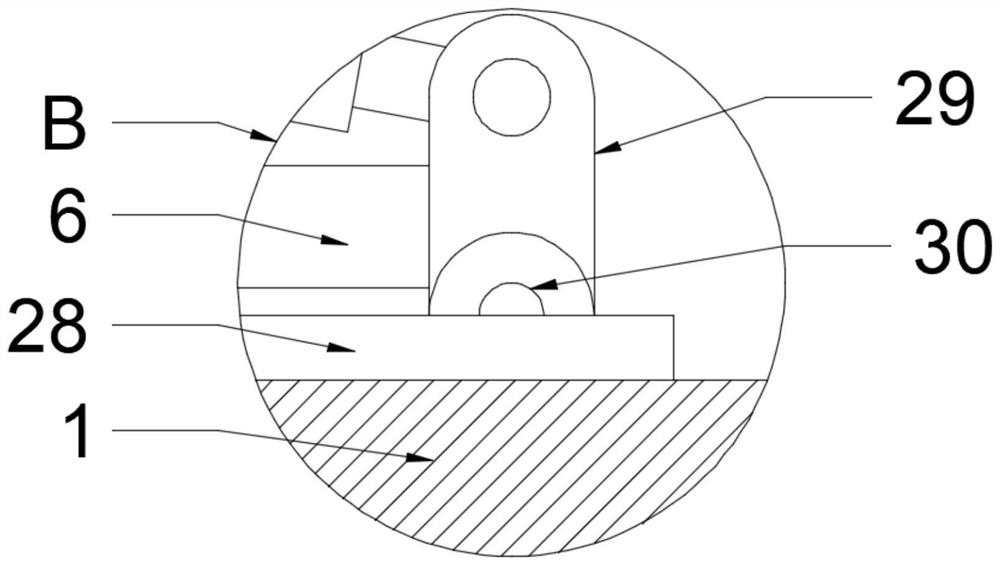

[0021] see Figure 1-3 , a lifting device for building construction, comprising a base 1 and a lifting platform 14, a support plate 24 is installed above the base 1, a cylinder 5 is fixedly installed on the upper surface of the base 1, and the cylinder 5 and the base 1 are fixedly connected by welding , the cylinder 5 is connected to the telescopic rod 6, the end of the telescopic rod 6 away from the cylinder 5 is fixedly connected to the movable seat 29, the bottom of the movable seat 29 is fixedly connected to the pulley 30, and the right side of the cylinder 5 is equipped with a chute 28, The chute 28 is welded on the upper surface of the base 1, the pulley 30 is installed in the chute 28, the pulley 30 can move left and right in the horizontal direction in the chute 28, and the symmetrical installation between the base 1 and the support plate 24 is movable. Seat 29, pulley 30 and chute 28, described movable seat 29 rotates and connects cross lifting rod 8, and fixed seat 4...

Embodiment 2

[0026] see Figure 1-4 , on the basis of Embodiment 1, in order to enable the lifting platform 14 to reach a higher height, the upper surface of the support plate 24 is symmetrically installed with a driving motor 17, and the output end of the driving motor 17 is fixedly connected to the rotating shaft 23, and the rotating shaft 23 is fixed Connect the bevel gear one 22, the left and right sides of the drive motor 17 are symmetrically installed screw mandrels 19, the screw mandrels 19 are rotationally connected with the support plate 24, the bevel gear two 21 is fixedly installed below the screw mandrel 19, the bevel gear one 22 meshes with bevel gear 2 21, and the moving seat 20 is installed on the surface of the screw mandrel 19, and the moving seat 20 on the left and right sides can move up and down in the vertical direction under the rotation of the screw mandrel 19, and the moving seat 20 on the left and right sides The support plate 16 is fixedly installed, and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com