Double-winch double-cable circulation adverse slope logging method for steep mountain

A technology of skidding and winch, which is applied in the direction of hoisting device and hoisting device, etc., can solve the problems of insufficient gathering efficiency of winches and high labor intensity of workers, so as to solve the problem of insufficient gathering efficiency, improve gathering efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

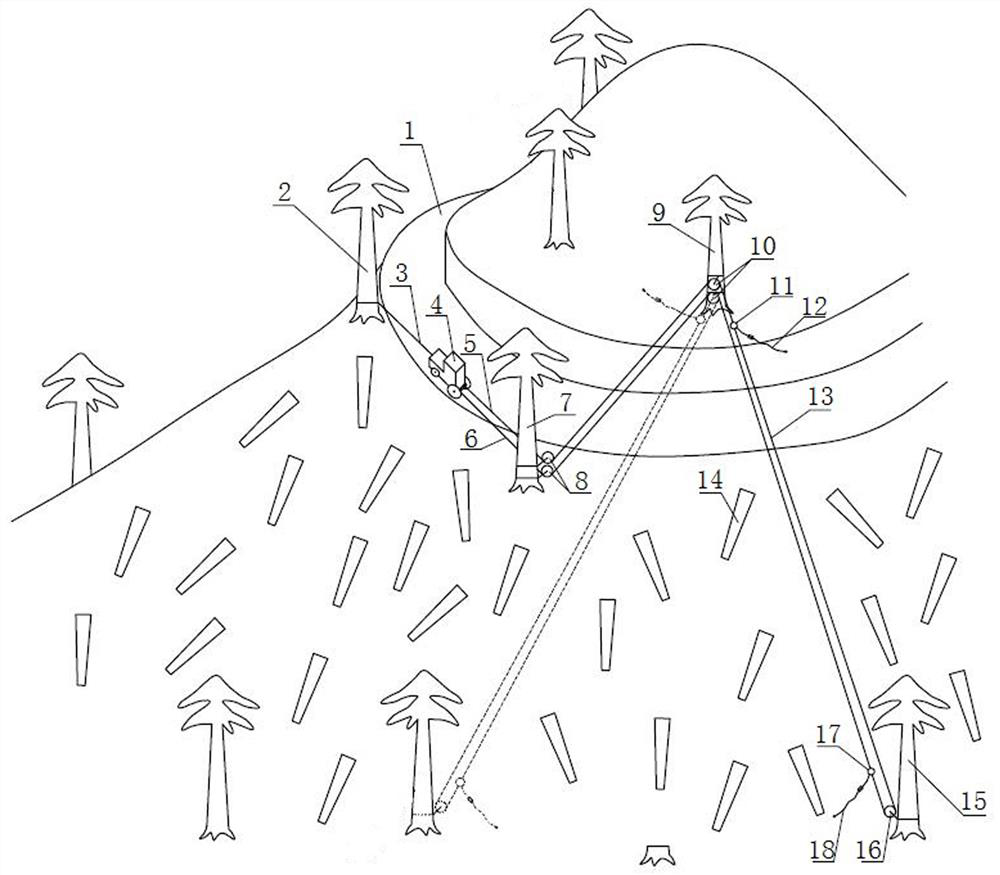

[0023] Such as figure 2 The shown double-winch and double-cable circular reverse-slope logging method for steep mountainous terrain includes the following steps:

[0024] Step 1: Drive the double winch skidding tractor 4 to the forest road 1 above the cutting area, select the anchor wood Ⅰ 2 in front of the double winch skidding tractor 4 to fix the double winch skidding tractor 4, and then use the mandrel 3 to set the double winch Timber tractor 4 is anchored;

[0025] Step 2: Two winches are installed at the tail of the double-winch skidding tractor 4, and the corresponding reels of the two winches are respectively wound around the fixed end of the traction cable I5 and the fixed end of the traction cable II6, and the two reels can be independently controlled Forward and reverse rotation and idling;

[0026] Step 3: Select the anchor wood II7 at the rear and lower part of the skidding tractor 4 with double winches as the first fulcrum of the cable, and fix and install two...

Embodiment 2

[0033] The difference between this embodiment and Example 1 is that: the anchor wood I2, the anchor wood II7, the anchor wood III9 and the anchor wood IV15 are all cut roots.

Embodiment 3

[0035] The difference between this embodiment and embodiment 1 lies in that: the wooden binding cable I12 and the wooden binding cable II18 are respectively connected to the iron ring I11 and the iron ring II17 through hooks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com