Stranding device for steel wire rope

A technology for a steel wire rope and a wire crimping device is applied in the field of twisting devices, which can solve the problems of inconvenient disassembly and replacement of a pay-off reel and a take-up reel, affecting the production efficiency of the wire rope, and low forming efficiency of the wire rope, etc. High efficiency, easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

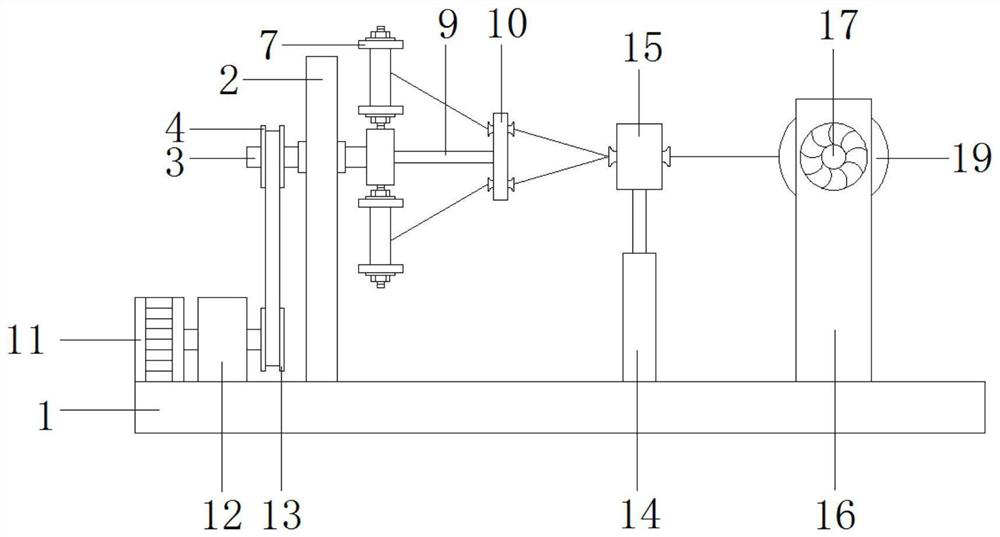

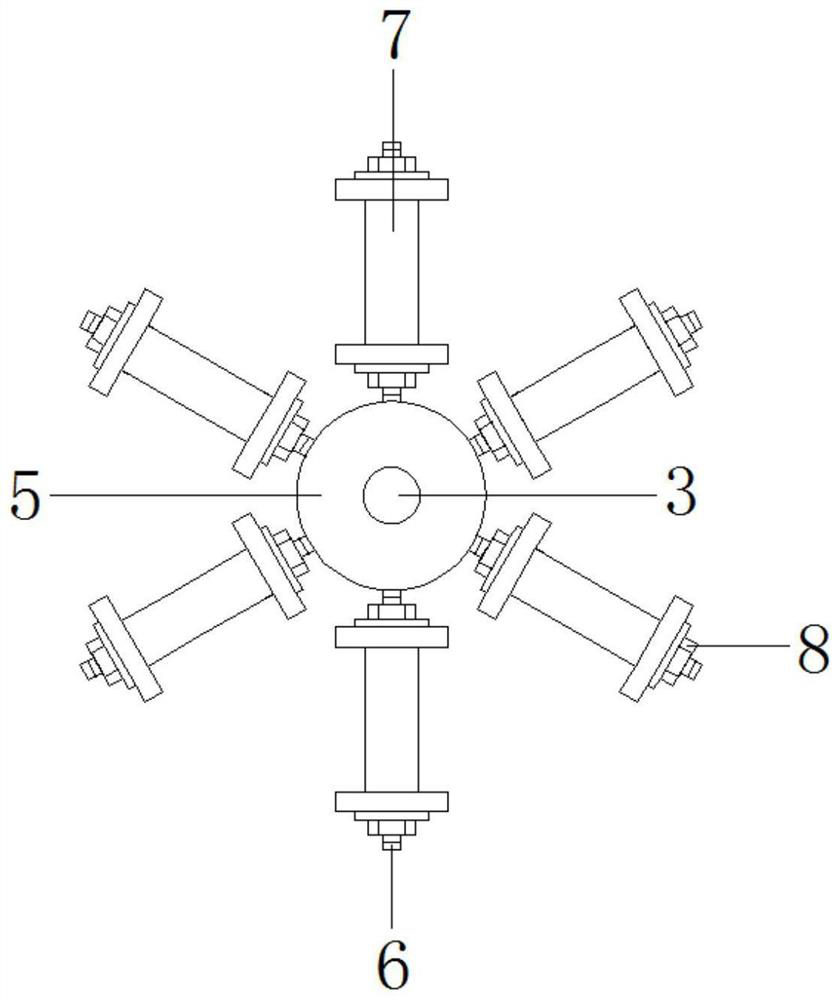

[0020] Such as Figure 1-Figure 4 As shown, the twisting device for steel wire rope provided by the present invention includes a base 1, a vertical plate 2 is fixedly arranged on the top of the base 1, and a pillar 3 is arranged on the top of the vertical plate 2 through a rotating shaft, and a fixed sleeve at one end of the pillar 3 is provided with a The other end of the moving wheel 4 is fixedly provided with a turntable 5, and the outside of the turntable 5 is equidistantly fixed with a first threaded rod 6, and the first threaded rod 6 is connected to the turntable 5 through a rotating shaft, and the outer side of the first threaded rod 6 is sleeved There is a thread reel 7, one side of the turntable 5 is fixedly provided with a rotating rod 9, one end of the rotating rod 9 is fixedly provided with a twisting disc 10, and the top of one side of the base 1 is fixedly provided with a first drive motor 11, and the first drive motor 11 drives The shaft end is fixedly connecte...

Embodiment 2

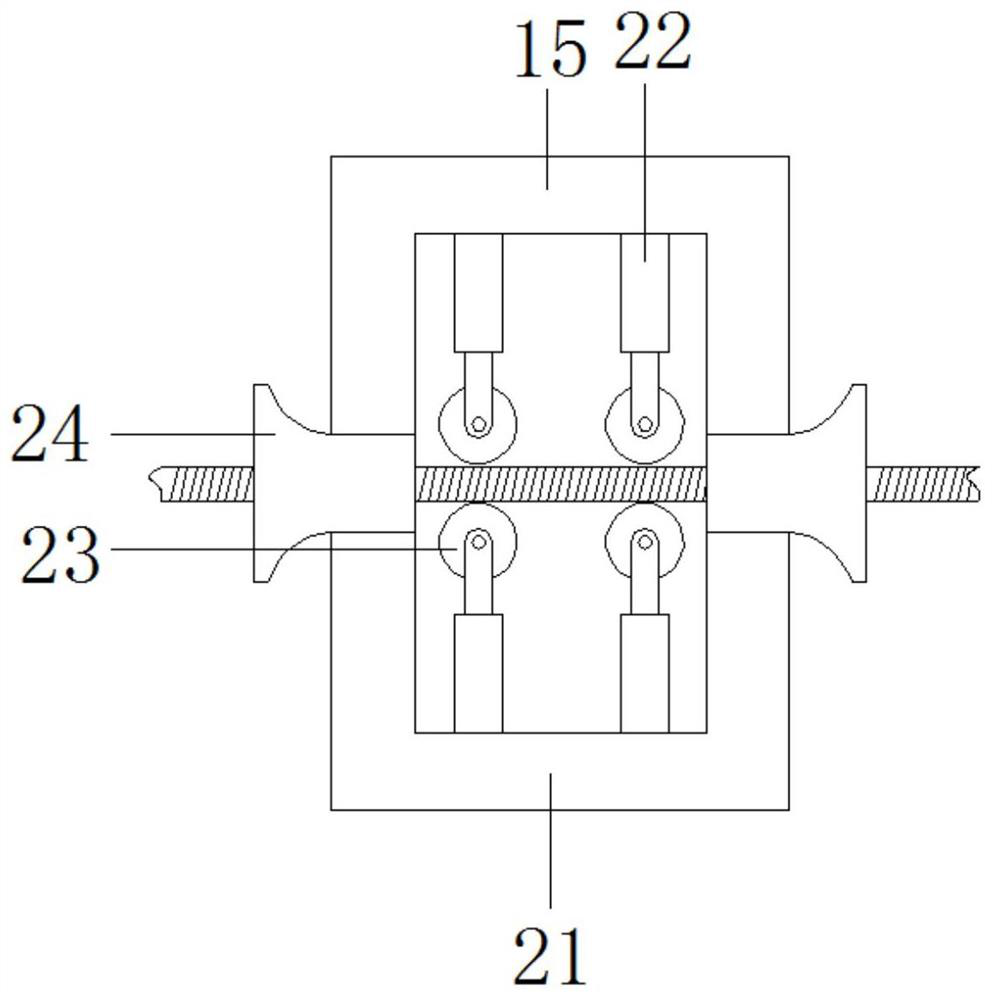

[0025] This embodiment 2 is based on embodiment 1, such as image 3 As shown, the wire crimping device 15 includes an outer shell 21, the top and bottom of the inner cavity of the outer shell 21 are symmetrically fixed with a hydraulic rod 22, the end of the hydraulic rod 22 is fixed with a crimping roller 23, and the two sides of the outer shell 21 are symmetrically provided with threading rods. port 24, and the threading port 24 is set as a funnel, the hydraulic rod 22 can control the lifting of the crimping roller 23, and the crimping roller 23 can integrate the steel wire rope passing through the middle part of the outer housing 21.

[0026] Working principle of the present invention: the first driving motor 11 can drive the driven wheel 4 to rotate through the driving wheel 13, and the driven wheel 4 can drive the turntable 5 and the twisting disk 10 to rotate synchronously through the pillar 3, and the steel wire on the branching reel 7 can be twisted. Wire rope is made,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com