Steel structure building

A technology for steel structures and buildings, applied to building components, building structures, roofs, etc., can solve problems such as difficult disassembly, unhygienic, and affecting the service life of steel structure buildings, and achieve good sealing performance and reliable use and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

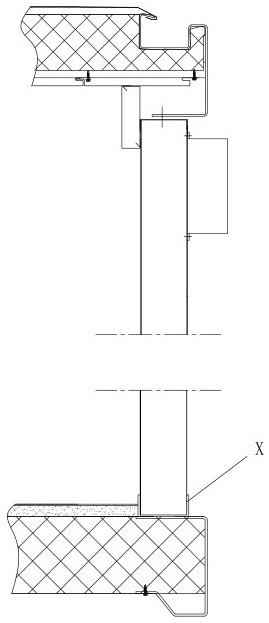

[0022] like figure 1 As shown, a kind of steel structure building in the prior art is provided in the accompanying drawing, only schematically shows the connection structure of the base and the wallboard of this building in the figure, and it comprises base, riser and top beam, can be seen from the figure It can be clearly seen that the base is connected with U-shaped fasteners, the vertical plate is inserted into the U-shaped fastener, and the bottom of the roof beam and the top of the vertical plate are connected by self-tapping screws. For a steel structure building of this structure, the vertical plate and the base There will inevitably be a gap between the U-shaped fastener and the vertical plate at the joint, that is, figure 1 There will be water ingress problems at X in the building, which will reduce the service life of the entire steel structure building and greatly reduce its quality.

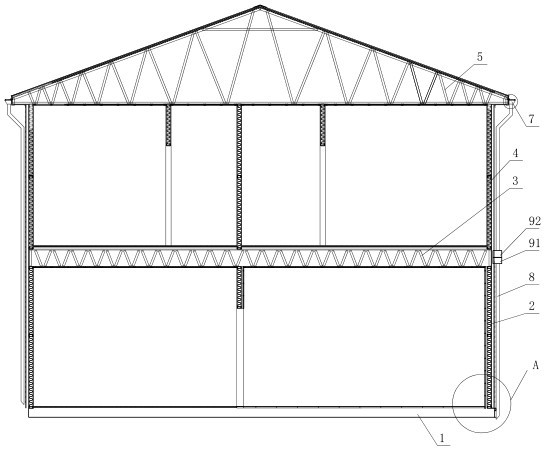

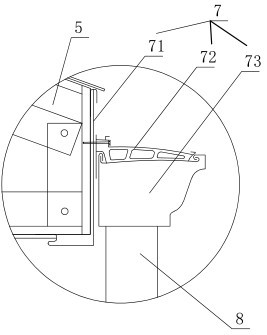

[0023] refer to figure 2 and Figure 4 As shown, the present invention provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com