Diffraction grating design method and system

A diffraction grating and design method technology, applied in the field of semiconductors, can solve the problems of destroying even diffraction orders and missing orders, reducing the contrast of measurement signals, etc., so as to avoid a large number of calculations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

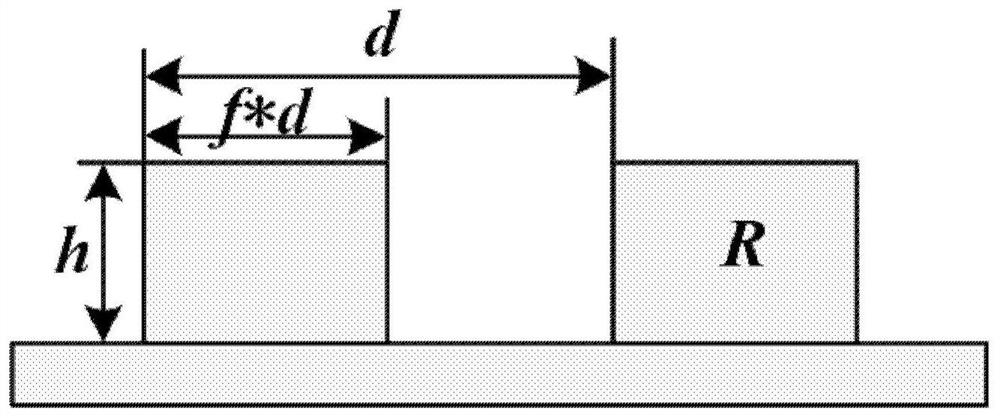

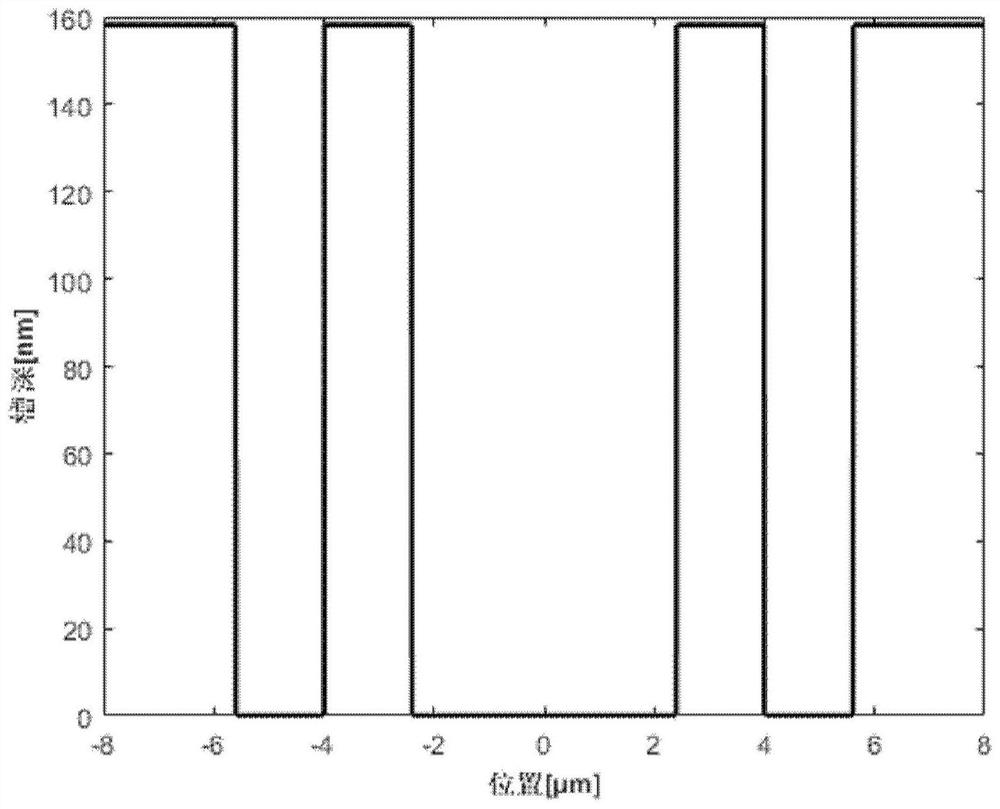

[0031] This publication provides a method and system for designing a diffraction grating, which solves the problem of a large amount of calculation in the process of scanning the grating marking. The method is firstly based on the conditions of each diffraction order enhancement and lack of order, and then according to the phase grating required enhancement and For the diffraction order of lack of order, select the grid level width and position information that meet the requirements, and obtain the phase grating structure that meets the requirements. This method selects the corresponding grid level and grid groove width and position according to the diffraction order that needs to be enhanced. It is necessary to set the entire grating structure as the optimization condition for optimization, avoiding a large number of calculations.

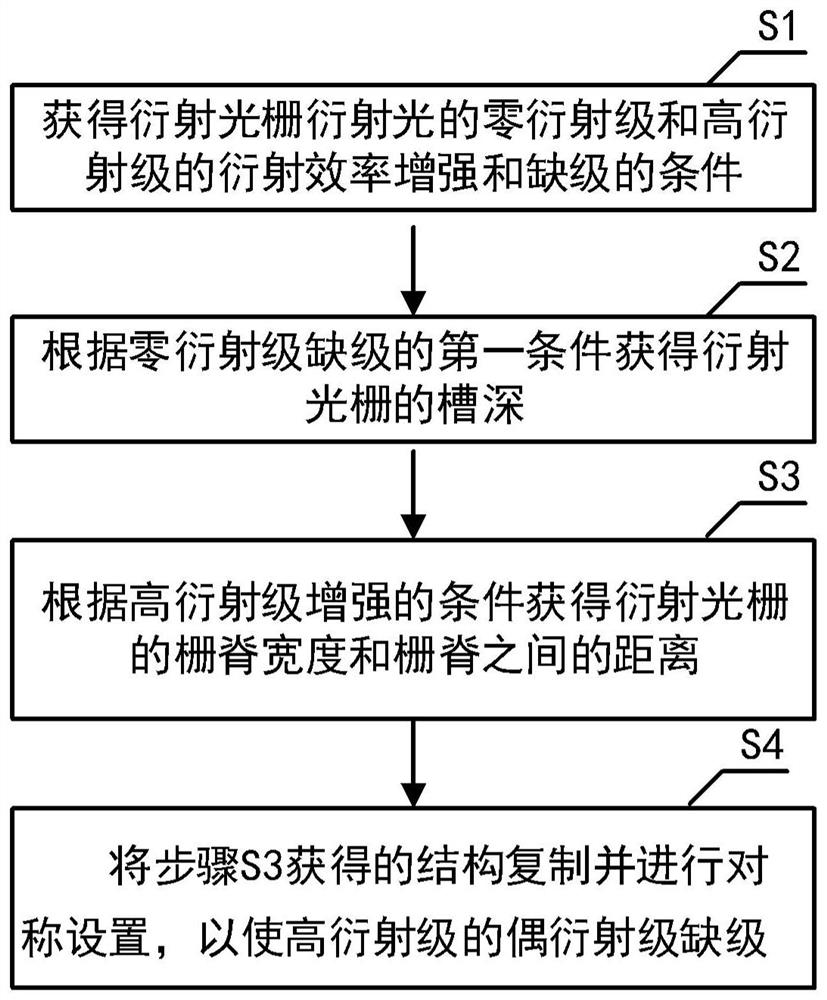

[0032] The present disclosure provides a method for designing a diffraction grating, such as figure 1 As shown, it includes: S1, the conditions f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com